We may use this info to send you notifications about your account, your institutional access, and/or other related products. If the pressure ratio across the nozzle is at least: then the flow at the throat will be sonic (\(M = 1\)) and the flow in the diverging section will be supersonic. enthalpy plus the square of the exit velocity divided by two. Here, the pressure at the exit is referred to as the back-pressure, and the pressure at the entry is the stagnation pressure. Nozzle Analysis: Variations in Mach Number and Pressure Along a Converging and a Converging-diverging Nozzle. ratio depends on the exit static pressure and the In a converging-diverging nozzle, the converging section is followed by a divergent nozzle section and is designed in a way such that flow gets choked at the throat of the converging section, thereby fixing the mass flow rate in the system. Here, m-dot is the mass flow rate through the nozzle, T-zero is the stagnation temperature, AT is the area of the throat, and p-zero is the stagnation pressure. Connect the pressure measurement system to the data acquisition interface to collect real-time data readings. The back-pressure (pB) is the driving factor that determines the flow condition in the nozzle. We can also determine the nozzle total Open the mechanical flow control valve to start the airflow. &= \sqrt{\frac{2 \gamma}{\gamma - 1} \mathcal{R} \frac{T_c}{\mathcal{M}} \left(1 - \left( \frac{p_e}{p_c} \right)^{\frac{\gamma - 1}{\gamma}} \right)}\end{split}\], \[\frac{p_e}{p_c} \rightarrow 0 \quad \Rightarrow \quad 1 - \left( \frac{p_e}{p_c} \right)^{\frac{\gamma - 1}{\gamma}} \rightarrow 1\], \[\frac{A_1}{A_2} = \frac{v_2 \rho_2}{v_1 \rho_1}\], \[\frac{A_1}{A_2} = \frac{M_2}{M_1} \left( \frac{1 + \frac{\gamma - 1}{2} M_1^2}{1 + \frac{\gamma - 1}{2} M_2^2} \right)^{\frac{\gamma + 1}{2 (\gamma - 1)}}\], \[\frac{p_c}{p_e} > \left( \frac{\gamma + 1}{2} \right)^{\frac{\gamma}{\gamma - 1}} \sim 1.8\], \[v_t = \sqrt{\gamma R T_t} = \sqrt{\frac{2 \gamma}{\gamma + 1} R T_c}\], \[\dot{m} = A_t v_t \rho_t = A_t p_c \frac{\gamma}{\sqrt{\gamma R T_c}} \left( \frac{2}{\gamma + 1} \right)^{\frac{\gamma + 1}{2 (\gamma - 1)}}\], \[F = A_t p_c \sqrt{\frac{2 \gamma^2}{\gamma - 1} \left( \frac{2}{\gamma + 1}\right)^{\frac{\gamma + 1}{\gamma - 1}} \left(1 - \left( \frac{p_e}{p_c} \right)^{\frac{\gamma - 1}{\gamma}} \right)} + (p_e - p_a) A_e\], \[C_F = \sqrt{\frac{2 \gamma^2}{\gamma - 1} \left( \frac{2}{\gamma + 1}\right)^{\frac{\gamma + 1}{\gamma - 1}} \left(1 - \left( \frac{p_e}{p_c} \right)^{\frac{\gamma - 1}{\gamma}} \right)} + \frac{p_e - p_a}{p_c} \frac{A_e}{A_t}\], \[\begin{split}\epsilon &= \frac{A_e}{A_t} = \frac{\rho_t v_t}{\rho_e v_e} \\ The MFP increases with decreasing back-pressure ratio up until 0.6, which corresponds to expected behavior, as mass flow should increase as the back-pressure ratio decreases. We recommend downloading the newest version of Flash here, but we support all versions 10 and above. Please click here to view a larger version of this figure. The overall trends inp/pOdistribution matches theoretical trends fromFigure 3. FromFigure 8, we observe that as thepB/pOratio decreases(until 0.5283), flow at every section of the nozzle is subsonic and increases with decreasing area. thrust and specific impulse). Substituting = 1.4 (specific heat ratio for dry air) in Equation 2, we obtain a back-pressure ratio of: Equation 3 defines the boundary between the non-choked and choked flow regimes. EPR depends on the pressure ratio of all vacuum) engine. This allows the design of a nozzle geometry which will accelerate the flow the high speeds needed for rocket propulsion. Subsonic flow that reaches choked condition but does not attain supersonic velocities (considered isentropic). JoVE, Cambridge, MA, (2022). More. JoVE, Cambridge, MA, (2022). thrust equation slide. As back-pressure is decreased, the flow velocity along the converging section increases, as well as the Mach number, with its peak value at the throat. We use cookies to enhance your experience on our website. The station of minimum area in a converging-diverging nozzle is known as the nozzle throat. temperature from the engine temperature ratio Schematic of a converging nozzle. We can also look at the Mach number across the length of the converging-diverging nozzle to examine flow conditions at varying back-pressure ratios. The purpose of a rocket is to generate thrust by expelling mass at high velocity. Please check your Internet connection and reload this page. All rights reserved, A nozzle begins at the point where the chamber diameter begins to decrease. Connect the pressure measurement system to the graphical software interface for real-time pressure data reading. One of the governing isentropic relations between Mach number (M), nozzle area (A), and velocity (u) is represented by the following equation: where u is the velocity, A is the nozzle area, and M is the Mach number. A subscription to JoVE is required to view this content.You will only be able to see the first 20 seconds. Most modern passenger and military aircraft are powered by

Subsonic flow that never reaches choked condition. Consider two gas states, 1 and 2, which are isentropically related (\(s_1 = s_2\)). , ETR. Over-expanded flow the pressure at the nozzle exit is lower than the ambient pressure, causing the jet exiting the nozzle to be highly unstable with huge variations in pressure and velocity as it travels downstream. However, it should be noted that the data at the throat corresponds to port 9, which is slightly before the actual throat. thrust equation for the amount of thrust The rest of this page derives the nozzle flow theory, and demonstrates other features of proptools.nozzle. Beyond the throat exit, there is uncontrolled expansion of the flow, leading to supersonic Mach numbers. Here, the normal shock causes a sudden drop in velocity and an increase in back-pressure, as indicated by the sudden increase in. Unable to load video. Figures 8 and 9 show the variation in pressure ratio and Mach number across the length of the nozzle (normalized based on total nozzle length) for various back-pressure settings for the converging and converging-diverging nozzles, respectively. This is the thrust coefficient, \(C_F\): For an ideal nozzle, the thrust coefficient is: Note that \(C_F\) is independent of the combustion temperature or the engine size. Mount the converging nozzle in the center of the nozzle test rig, as shown in. Your access has now expired. If the pressure at the nozzle exit is lower than the ambient pressure, the jet exiting the nozzle is highly unstable with variations in pressure and velocity. The nozzle accelerates the gas by converting some of the gass thermal energy into kinetic energy. For vehicles like rockets and military aircraft, which must travel at and above the speed of sound, a converging-diverging nozzle, as illustrated in Figure 2, is used. You have unlocked a 2-hour free trial now. This is why many rockets burn hydrogen and oxygen: they yield a high flame temperature, and the exhaust (mostly H2 and H2O) is of low molar mass. An efficiency factor nn has been included here to account for all the Analysis of the converging-diverging nozzle provides insight into how supersonic flow velocities can be achieved once flow gets choked at the throat. is equal to the static Another common nozzle is the converging-diverging nozzle, which has a section of decreasing area, followed by a section of increasing area. Decrease the back-pressure ratio in steps of 0.1, down to a ratio of 0. total enthalpy ht Therefore, the flow is adiabatic. This result is expected as flow increases up to the choked condition. pressure ratio NPR. Please enjoy a free 2-hour trial. If you do not see the message in your inbox, please check your "Spam" folder. With a Rotate the valve to adjust the flow rate to obtain a back-pressure ratio (. Now, take the zero flow condition pressure reading. You can explore the design and operation of \(c^*\) is independent of the nozzle expansion process. Subsonic flow that reaches choked condition, with the resulting supersonic flow forming a normal shock, which then experiences subsonic deceleration. Based on Figure 3, the following are the flow conditions that can be observed in a converging nozzle: Figure 3. The fixed-expansion nozzles perform well at their design altitude, but have lower \(C_F\) than a matched nozzle at all other altitudes.

In summary, we learned how varying cross sections of nozzles accelerate or decelerate flow in propulsion systems. There are two main types of nozzles: the converging nozzle and the converging-diverging nozzle. One of the governing isentropic relations between Mach number (. ) Ideal nozzle flow is a simplified model of the aero- and thermo-dynamic behavior of fluid in a nozzle. """, # Exhaust heat capacity ratio [units: dimensionless], # Exhaust molar mass [units: kilogram mole**1], # Thrust coefficient [units: dimensionless], # Characteristic velocity [units: meter second**-1], # Propellant mass flow [units: kilogram second**-1], \(\frac{p_0}{p} = \left( \frac{T_0}{T} \right)^{\frac{\gamma}{\gamma - 1}}\), 'Isentropic flow relations for $\gamma={:.2f}$'. The stagnation enthalpy \(h_0\) is the sum of the static enthalpy and the specific kinetic energy: For a calorically perfect gas, \(T = h / c_p\), and the stagnation temperature is: It is helpful to write the fluid properties in terms of the Mach number \(M\), instead of the velocity. 1, recording the measurements at each increment like before. Next, using the data collected, we can calculate the mass flow parameter, MFP, using the equation shown. b. As the nozzle area decreases, the flow velocity increases, with the maximum flow velocity occurring at the nozzle throat. Aeronautical Engineering. At subsonic speeds, Mach number increases as the area is decreased. However, the experimental results showed the mass flow parameter decreasing for lower values of back-pressure ratio instead of plateauing once the maximum value was achieved, as predicted by theory. %IshDDJJ 7&I@&IIy= I X$n- A2,S6z+5]KyU=*kB*ij*6UOQtBNJ'zHzbo2Mv^/eq@)tTh @'V4`=3[[)0T`;Bj#v)`+xV3c[yhf".0OY=g3V>~suWx;p*RJ0 9a+{'-)2Mq. Figure 4 shows the following seven profiles in the position versus pressure ratio plot. Record the stagnation pressure and atmospheric pressure from the pressure measurement system and the temperature from the temperature sensor. Please recommend JoVE to your librarian. Choked flow, where any pressure drop does not accelerate the flow. In order to design nozzles to suit a given application, an understanding of the flow behavior and factors that affect said behavior for a range of flow conditions is essential for designing efficient propulsion systems. sea level) engine has a smaller expansion ratio than the second stage (e.g.

The mass flow parameter versus the back-pressure ratio is also plotted and studied for both the nozzles.

Please click here to view a larger version of this figure. conditions. The following plot shows \(C_F\) vs altitude for our example engine with two different nozzles: a small nozzle suited to a first stage application (blue curve) and a large nozzle for a second stage (orange curve). To conserve mass, the ratio of areas between any two points along the nozzle axis must be: Use the isentropic relations to write the velocity and density in terms of Mach number, and simplify: We can use proptools to plot Mach-Area relation. The nozzle performance equations work just as well for rocket a. It is the ratio of exit area to throat area: The expansion ratio appears directly in the equation for thrust coefficient. nozzle simulator program which runs on your browser. ETR depends on the temperature ratio of all the other

A comparison of the pressure trends obtained for both the converging and converging-diverging type nozzles with theoretical results was excellent. Tt8 divided by Tt5 is 1.0. At very low back-pressure ratios, the flow isentropically expands and remains supersonic throughout the diverging nozzle, reaching Mach numbers greater than one. The nozzles are run for different back-pressure settings to analyze the internal flow in the nozzles under varying flow conditions, identify the various flow regimes, and compare the data to theoretical predictions. As the nozzle area decreases, the flow velocity increases, with the maximum velocity occurring at the throat. Nozzle Analysis: Variations in Mach Number and Pressure Along a Converging and a Converging-diverging Nozzle. Small expansion ratios are used for space launch boosters or tactical missiles, which operate at low altitudes (high ambient pressure). If the problem continues, please, An unexpected error occurred. 377, No. As the back-pressure decreases, the Mach number increases across the converging section while decreasing across the diverging section. At this point, the flow at the throat gets choked, meaning that any further increase of inlet flow velocity will not increase the flow velocity at the throat.

Observations of the Mach number variation across the nozzle show subsonic flow until the pressure ratio at the throat equals the choked flow condition of 0.5283. Older browsers that do not support HTML5 and the H.264 video codec will still use a Flash-based video player.

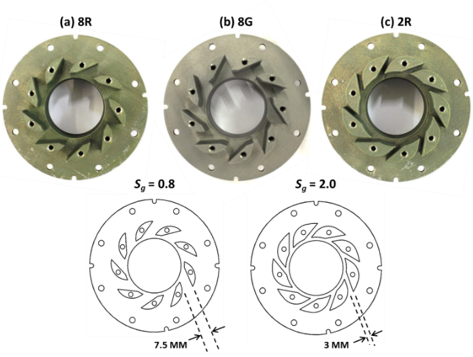

Set state 2 to be the state at the nozzle exit: \(p_2 = p_e, v_2 = v_e\). Please click here to view a larger version of this figure. You have already requested a trial and a JoVE representative will be in touch with you shortly. As the pressure ratio goes to zero, the exit vleocity approaches its maximum for a given \(T_c, \mathcal{M}\) and \(\gamma\). Beyond the throat/nozzle exit, there is uncontrolled expansion of the flow, leading to supersonic Mach numbers. turbojet and rocket nozzles with our interactive Copyright 2019 by Song Chen and Mihai Mihaescu. 2159, 2022 American Institute of Aeronautics and Astronautics, American Institute of Aeronautics and Astronautics, Journal of Guidance, Control, and Dynamics, Journal of Thermophysics and Heat Transfer, Source Localization of Crackle-Related Events in Military Aircraft Jet Noise, Coherence Analysis of the Noise from a Simulated Highly Heated Laboratory-Scale Jet, Modelling of jet noise: a perspective from large-eddy simulations. Figure 6. When the stagnation pressure equals the back-pressure, there is no flow. The trends inMFPfollow theoretical results untilpB/pO= 0.6 but start decreasing instead of plateauing for lower values of back-pressure ratios. Converging nozzles, as shown in Figure 1, are tubes with an area that decreases from the nozzle entry to the exit (or throat) of the nozzle. thrust developed by a jet engine. Geometry of converging nozzle. Recall that the back-pressure measurement was made at port 10. Let's look at the Mach number across the length of the nozzle. Nozzle flow theory can predict the thrust and specific impulse of a rocket engine. and Accessibility Certification, + Equal Employment Opportunity Data Posted Pursuant to the No Fear Act, + Budgets, Strategic Plans and Accountability Reports. This could be the most likely reason for the incorrect MFP reading. sets the total mass flow rate through the Results for the converging-diverging nozzle (from top-right, clockwise) variation in pressure ratio across the nozzle; variation in Mach number across the nozzle; and variation in mass plow parameter with back-pressure ratio. Considering the energy equation for It depends only on the heat capacity ratio, nozzle pressures, and expansion ratio (\(A_e / A_t\)). As observed in Figure 3, until choked flow, the MFP continues to increase. Using this of jet engines, but all jet engines have some partsin common. It is therefore a figure of merit for the combustion process and propellants. The stagnation state is the state a moving fluid would reach if it were isentropically decelerated to zero velocity. The first stage (e.g. The condition at which choked flow occurs can be calculated using the isentropic relation: where is the specific heat ratio of the fluid. nozzle total pressure. A convergent-divergent nozzle will have supersonic At supersonic speeds (\(M > 1\)), Mach number increases as area increases. The pressures are measured using an external sensor, and the mass flow rates are measured by a pair of rotameters connected in series right before the nozzle exhaust. Referring to our station Based on the design of the converging-diverging nozzle, the flow velocity after the nozzle throat can either: (i) decrease to subsonic velocities, (ii) become supersonic, cause a normal shock, and then decrease to subsonic velocities at the nozzle exit, or (iii) remain supersonic throughout the diverging section. Alternatively, the flow can form a shock when it expands in the diverging section. Please click here to view a larger version of this figure.

Please click here to activate your free 2-hour trial. Geometry of converging-diverging nozzle. Please follow the link in the email to activate your free trial account. Science Education (Aeronautical Engineering), Aerodynamic Performance of a Model Aircraft: The DC-6B, Airfoil Behavior: Pressure Distribution over a Clark Y-14 Wing. These equations are fundamental tools for the preliminary design of rocket propulsion systems. A nozzle is a device that is commonly used in aerospace propulsion systems to accelerate or decelerate flow using its varying cross section. The flow is quasi one dimensional.

Use proptools to plot thrust versus chamber pressure for the example engine: Note that thrust is almost linear in chamber pressure. If that doesn't help, please let us know. For the no flow condition, again the Mach number is zero. In this demonstration, the converging and converging-diverging nozzles - two of the most common nozzle types used in aerospace applications - were tested using a nozzle test rig.

Once the flow exits the nozzle, it undergoes an expansion, due to the sudden increase in area that could lead to (uncontrolled) supersonic flow velocities. Figure 8. First, flow reaches the choked condition at the throat and decelerates subsonically in the diverging section. the exit velocity Ve = V8: V8 = sqrt(2 * nn * cp * Tt8 * [1 - (1 / NPR)^((gam -1 ) / gam)] ). Copyright 2022 MyJoVE Corporation. @1m9S6!BhmN-E"7AO?0ZHSvL 1 # Solve for the exit pressure [units: pascal]. velocity, and the mass flow rate through the engine, we can solve the For an ideal rocket at matched exit pressure, \(I_{sp} = v_2 / g_0\).

While the pressures are measured using an external sensor, the mass flow rates in the nozzle are measured by a pair of rotameters placed right before the exhaust of the nozzle test rig. It is for this reason that converging nozzles are used to accelerate fluids in the subsonic flow regime alone and can commonly be found on all commercial jets (except for the Concord) as they travel at subsonic speeds. Both of the nozzles tested have 10 ports, enabling pressure measurements throughout the length of the nozzle. Further reduction ofpB/pOshows three distinct patterns: +

some important design features of the nozzle. Because the flow is quasi- one dimensional, the mass flow through every cross-section of the nozzle must be the same: where \(A\) is the cross-sectional area of the nozzle flow passage (normal to the flow axis). vacuum) engine. At and belowpB/pO= 0.5283, the Mach number at the throat (normalized nozzle distance = 0.93) does not exceed one. + Budgets, Strategic Plans and Accountability Reports Use proptools to compute the mass flow of the example engine: The thrust force of a rocket engine is equal to the momentum flow out of the nozzle plus a pressure force at the nozzle exit: where \(p_a\) is the ambient pressure and \(A_e\) is the nozzle exit area. This clearly demonstrates that the flow is choked at the throat.

some important design features of the nozzle. Because the flow is quasi- one dimensional, the mass flow through every cross-section of the nozzle must be the same: where \(A\) is the cross-sectional area of the nozzle flow passage (normal to the flow axis). vacuum) engine. At and belowpB/pO= 0.5283, the Mach number at the throat (normalized nozzle distance = 0.93) does not exceed one. + Budgets, Strategic Plans and Accountability Reports Use proptools to compute the mass flow of the example engine: The thrust force of a rocket engine is equal to the momentum flow out of the nozzle plus a pressure force at the nozzle exit: where \(p_a\) is the ambient pressure and \(A_e\) is the nozzle exit area. This clearly demonstrates that the flow is choked at the throat.