Having the advantages of standard PCD scribing wheels as well as top grade carbide wheels.

Multi-head glass cutting machine is the only one that achieves high quality and efficiency ultra thin glass cutting in China.

Features and advantages of diamond PCD axles:  Dont be shy get in touch! Wanted information on pencil tipped glass cutters, they look like a pencil and the diamond is buried within the shainless shaft, 1).

Dont be shy get in touch! Wanted information on pencil tipped glass cutters, they look like a pencil and the diamond is buried within the shainless shaft, 1).

Adopting the advanced technology from Japan.

1). I roll the wheel on my hand an few times to see if it is rolling well. Pressure as light as 5 or 6 pounds, upon a 120 to 140 degree wheel on thin glass; Pressure as heavy as 20+ pounds, with a 154 to 160 degree wheel, on very thick glass.

General purpose glass is mostly made by the float glass process and is obtainable in thicknesses from 1.5 to 25mm (116 to 1in). As you become more experience with glass working, you will learn the different characteristics of the glass. This shortens the training period of workers to a great extent and provides the very solution to poor capacity of most glass manufacturers.

A burr in the wheel will cause the cutter to skip and cause the glass to erratically break.

I think they go for a couple of dollars.

The desktop is flat and precise especially for cutting optical glass. The cutter is then rolled firmly over the glass, producing a "score line" or "fissure," weakening the glass along this line. I prefer to cut by wall mount cutter. I think it has a diamond tip.  Between the 14th and 16th centuries, starting in Italy, a diamond-tipped cutter became prevalent which allowed for more precise cutting.

Between the 14th and 16th centuries, starting in Italy, a diamond-tipped cutter became prevalent which allowed for more precise cutting.

Feel free to let me know if youd like to read a blog about something else to do with glass.

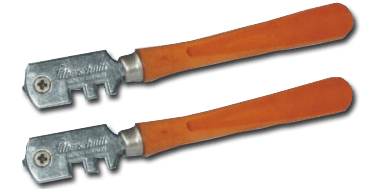

Features and advantages of diamond glass cutter: The type of grip depends on the cutters preference. The "L" shaped Fletcher cutter with the oil reservour is good. Another factor to successful glass cutting may be the height of your cutting table. When carbide wheels work with PCD axles, the service life of wheels is prolonged.

A smaller wheel (3mm (18in)) is appropriate for cutting patterns and curves since a smaller wheel can follow curved lines without dragging. 2). The moving system of the cutter head is composed of highly precise rods, tracks and high resolution decoder, which achieves the reliability, little error and high efficiency of the equipment. We dont all cut glass like they do in this video, but the tool is one that I know how to use, and Ill actually be using one this week to cut my full sheets into smaller squares for my students to use. This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. Diamond glass cutter varies in types to meet the requirements to cut different thickness of glass. 2). PCD axles assure the competence and longevity of PCD wheels.

More competitive price. In the Middle Ages, glass was cut with a heated and sharply pointed iron rod. There are so many different types of cutters.

They all work about the same, butit is important to find a cutter that fits your hand perfectly.

Consider adding glass fabrication to your area of expertise.

At present the applicable thickness of glass varies between 0.2mm and 19mm. There is more to a glass cutter than you might think. In the past Ive written about some of the techniques used to cut laminated glass and I urge you to look back for more information if youre interested. Theycan see if youare tilting yourcutter. To break it, grab each side of the cut with thumbs and forefingers and just break it like you were going to break a pencil of some such and pull the two pieces apart at the same time. Some cutters have a reservoir built into the handle for oil to be dispensed.

Thanks so much for everyones patience in answering my questions. When my dad passed on I found that I could not use either of his 2 cutters. 2). Applications in LCD panel and substrate, touch screen, auto glass, solar cell glass, medical glass, glass production line, glass tubes. Love it. I find this video enormously amusing and thats why Ive written this little blog about glass cutters. Could you clarify? It is divided into two types, fully automatic and manual respectively. Heres an example of the breath-taking items you can see if you get a chance to visit. 4). A glass cutter may use a diamond to create the split, but more commonly a small cutting wheel made of hardened steel or tungsten carbide 46mm in diameter with a V-shaped profile called a hone angle is used.

The effective cutting of glass also requires a small amount of oil (kerosene is often used) and some glass cutters contain a reservoir of this oil which both lubricates the wheel and prevents it from becoming too hot: as the wheel scores, friction between it and the glass surface briefly generates intense heat, and oil dissipates this efficiently.

Jenie Yolland acknowledges the Wurundjeri Woi Wurrung as the Traditional Owners of this country, pays tribute to all Aboriginal and Torres Strait Islander people in Yarra, and gives respect to the Elders past, present and emerging. Dont drop them point down on the workshop floor and dont store them around your flux.

Nevertheless, I have not examined the most important tool in glass fabrication, the glass cutter itself. As you can see from our student pictures above, we use the Toyo pencil cutter in our studios but other studios choose to use other cutters. But there are several different styles and manufacturers. You could damage your glass cutter going over the same score. 2). The early use of flint tools and grozing yrnes for cutting and shaping the glass is noted. [1] This is not to be confused with the tools used to make cut glass objects. Applications in LCD panels and substrates, touch screen, watch glass, auto glass, solar cell glass, medical glass, glass production line, glass tubes, etc.

3). But the diagram shows the opposite, that the larger value V is, the blunter the edge of the wheel will be. I have better mobility if I stand while cutting.

Their main drawback is that wheels with sharper hone angles will become dull more quickly than their more obtuse counterparts. Diamond scribing wheel (Non teeth LED screen cutting wheel), Cutting can be 90% mechanics and 10% luck so I hope that these tips can help you improve your cutting skills. Also, when using a bar, it helps to pull your cuttertowards yourself, rather than push away.

of finger pressure, while the pistol grip requires the same amount of pressure but requires more hand pressure versus finger pressure. The edge of the wheel is made into regular and equal teeth with the features of 4-300 teeth and the teeth depth tolerance of 1m, so this helps to deepen the crack depth and improve glass cutting quality. Features and advantages of single-head glass cutting machine: Though auto glass technicians cut from patterns, most cuts are straight, making the straight cut head preferred. You can choose between: Pistol Grip Photo Courtesy Delphi Glass. I can never cut a straight line by hand. 1). Adopting the same materials as Japanese top grade carbide wheels.

A 120 to 140 degree angle is (relatively) sharp as glass cutters go, and is suited to light pressure (as little as 5 or 6 pounds) to score thin glass, making a score line (fissure) 0.002 inches wide (2/1000). Remark: The working table size can be customized, and machine must match with air compressor of 0.2~0.8Mpa, power of 0.75~1.5KW, >> Diamond scribing wheel,diamond glass cutter,glass cutting tools&machine, High penetration diamond scribing wheel /LED cutting wheel (outer teeth PCD wheel). There are two types of cutting heads: straight cutting and pattern cutting. It guarantees perfect cutting line and crack surfaces, and additionally continuity and uniformity of glass cutting. Amazons description of the book reads This one-of-a-kind book describes some 1400 different glass cutters collected from around the world by the author during the past 35 years.

1). I often get customers that say I cant cut straight lines and I immediately ask are you using a bar or ruler that your cutter runs along when this happens.

Shipping, Payments and Returns First, the cutter. You are using an out of date browser.

Regular, annealed glass can be broken apart this way but not tempered glass as the latter tends to shatter rather than breaking cleanly into two pieces.[2]. Meanwhile, the straight cutting head is wider and does not pivot. Required fields are marked *. Open this link for more history of glass. Hybrid PCD scribing wheels are mainly applied to cutting glass with the thickness of 0.1mm5mm such as LCD panel and substrate, touch screen, optical windows, medical glass, auto glass, glass production line, ornamental glass, glass tubes. You only score once, never back and forth. Iridescent glass often needs more pressure because the metallic finish seems to make the surface harder. Happy cutting of glass.

Hybrid PCD scribing wheel (black&white high precision diamond glass/LED cutting wheel) 3). Both are applied to cutting glass with different thickness and hardness, because of the high cost-performance ratio and longevity, diamond scribing wheel are regarded as the expert cutters for borosilicate glass and tempered glass for example touch screen. These sheets are then broken out by hand into the individual sheets of glass (also known as "lites" in the glass industry). but heres the Amazon link to the book. Your email address will not be published.

We took many considerations when designing the multi head glass cutting machine, so workers can operate the machine proficiently only after one-hours training.

Straighten up the cutter and be amazed how easy it is to cut straight lines. 2). Most of us that do stained glass will agree that the Oil Fed Carbide wheel glass cutters work the best. I use the Fletcher hand cutter that is shaped like a utility knife. The glass is now weakened along this line and the sheet is ready to be split. Features and advantages of hybrid PCD/Diamond LED scribing wheels: Hybrid PCD scribing wheel (black&white high precision diamond glass/LED cutting wheel). A glass cutter is a tool used to make a shallow score in one surface of a piece of glass that is to be broken in two pieces. 3). Features and advantages of multi-head glass cutting machine: A glass cutter is a tool used to make a shallow score in one surface of a piece of glass (normally a flat one) that is to be broken in two pieces, for example to fit a window.

The scoring makes a split in the surface of the glass which encourages the glass to break neatly along the score. The service life is three times that of top grade carbide wheels, excellent cost-performance ratio.

Did you know that someone has actually written a book about glass cutters throughout history. The angle measured is that between the two facets of the wheel edge. Here are some pictures of others you can choose from. Hybrid PCD scribing wheels are mainly applied to cutting glass with the thickness of 0.1mm5mm such as LCD panel and substrate, touch screen, optical windows, medical glass, auto glass, glass production line, ornamental glass, glass tubes. When I was a child I used to enjoy a special treat that was a Blue Heaven MilkshakeI didnt iridized glass for bride inIndia When she saw this piece she loved it, well almost all of it. A smaller wheel (3mm (18 in)) is appropriate for cutting patterns and curves since a smaller wheel can follow curved lines without dragging and creating an uneven edge. These seem like unimportant items compared to most of the posts. Carbide scribing wheel The glass cutter in the photo has a ball on one end for tapping the glass. Applications in collaboration with various types of scribing wheels in glass cutting. Posted by :Bob Beranek On : September 6, 2018. Applications in LCD panels and substrates, touch screen, watch glass, auto glass, solar cell glass, medical glass, glass production line, glass tubes, etc. Some very beautiful specimens of this novel art were produced at Venice as early as 1562. Stable cutting quality: During the service life of the wheel, the glass cutting quality is stable and constant. I teach you all about what these terms mean in my courses. If you notice that your score is frothy and white, you may need to back off on the pressure. One of the most important factors that influence productivity of glass cutting is the precision of wheel holders and the adaptability between wheels and holders, and precision and longevity of wheel holders are guaranteed. At Lake Oswego, Oregon, USA is an amazing collection of ancient Venetian glass held in the Stroemple Collection. Economical PCD wheels are ground on both sides and characterized by sharp edge, long service life, stable cutting quality and lower price. Required fields are marked *. We produce diamond glass cutters with high cost-performance ratio, which can be equipped with different types of diamond PCD scribing wheels such as high penetration PCD scribing wheels, standard PCD scribing wheels, hybrid PCD scribing wheels, carbide scribing wheels etc.

My mom does a lot of stained glass, and loves her oil filled cutter. However, cutting your own laminated parts can put a few more dollars in your pocket if you have the equipment and time. When properly lubricated a steel wheel can give a long period of satisfactory service. High penetration diamond scribing wheel /LED cutting wheel (outer teeth PCD wheel) A brief history of flat window glass describes its manufacture, application, taxation, etc. I use sewing machine oil which works well as its so fine and it doesnt smell like kerosene. The glass may be further weakened by lightly tapping along the cut. If you can barely see the score, you may need more pressure. Deepening the crack depth: Compared with normal PCD scribing wheels, the crack depth is much deeper after high penetration wheels scribe glass. All Rights Reserved. Site Terms and Conditions, Click to share on Facebook (Opens in new window), Click to share on Pinterest (Opens in new window), Click to share on Tumblr (Opens in new window), Click to share on Twitter (Opens in new window), Click to email a link to a friend (Opens in new window), Stainless Steel Fusing Molds Made In The USA, Glass Bevel Clusters and Straight Line Bevels, Straight Line Bevels and Close Out-Bevel Glass Shapes, DIY Making your own Wine Bottle Fairy Garden. A list of corporate, product line, distributor, etc. Diamond Axle, PCD Axle, carbide Axle If this isnt it, your cuttermay have a nick in the wheel or just plain worn out. An easy test to see if your cutter is rolling properly is to geta piece of mirror and score5 or 6 straight scores about 1/4 apart. Medium penetration diamond scribing wheel. The earliest mention of the diamond being used for writing on glass occurs in the sixteenth century, which may be considered as the first application of the diamond to this purpose, were written by Francis the First of France with his diamond ring on one of the panes of glass in the amazing Castle of Champfort.

Now that we have the cutter worked out, there are a few important tipson scoring the glass. Average hand pressure with this size wheel often gives good results.

Thanks for your comments Roy. The ratio between the arc of the wheel and the pressure applied with the tool has an important bearing on the degree of penetration. I am grateful that you are buying our gift vouchers! [4] Their main drawback is that wheels with sharper hone angles will become dull more quickly than their more obtuse counterparts. If you are following acurve, make sure your elbow is pointing out as you scoreotherwise you may run into your body as you try to navigate the score. 4). I guess you all are ready for another of my "in the old days story" so here it is. When we were on holidays recently.