Excessive pressure drop in the liquid line due Refrigerant analyzers are available that meet or exceed SAE J2912 and can identify gas samples taken directly from the refrigerant system or storage containers. Normal compressor cycling on a rack system. Any trace dye coming out of this location is a sure sign of an evaporator leak. Get the BEST auto repair information Alldatadiy.com and Eautorepair.net are professional-grade shop manualsperiod. Install pump Synthetic-based PAG oils are used with R-134a systems. The unit is coming out of defrost (normal). Trace dye comes in different forms for a variety of fluids including: engine oil, transmission oil and engine coolant. Liquid refrigerant backed up in the receiver. An operational test will help you verify that all HVAC system controls and modes are operating correctly. The recovery unit will continue to operate, drawing in air from the leak source and adding it to the storage tank. ceiling. Wait 2-7 minutes. 5. down controls and a crankcase heater. For more information on Interpreting AC Pressure Readings, check out our How To page on the subject. cycles. To test for evaporator freezing, turn off the engine and leave the vehicle for a while. Air in the system. No traps or insufficient traps in the suction riser. No bleed resistor on the start capacitor. Always refer to the manufacturers instructions for proper use of the refrigerant analyzer. It is very important to have the correct amount of oil in the A/C system. Compressor - Loss of oil, Loss of oil pressure, or Cuts off on oil pressure control. Internally equalized expansion valve used on a

var _gaq = _gaq || [];

So we will take a look at pressure diagnosis, but we need to start by reviewing refrigerant and how to determine if it may be the cause of the concern. In other words, the low refrigerant charge causes the refrigerant is in the system to sit too long in the evaporator. Compressor oversized and the evaporator is undersized. The use

An AC system leak allows moisture into the system.  NOTE: Refrigerant oils (PAG lubricants) are available through the Nissan

250 PSI / 50 PSI = The system is overcharged and the condenser is not cooling. Place a temperature gauge in one of the air outlets in the passenger compartment. for a leak. 2. NOTE: Too much dye can affect the viscosity of the refrigerant oil. Also, a faulty evaporator temp sensor can prevent the system from shutting down once the evaporator has iced over. So you have to refer to the factory legends to learn the identification symbols and then refer back to circuit diagrams to find the splice and ground locations. There are several PAG oils with special additive packages and different viscosities, which are used in current Nissan and Infiniti vehicles, depending on the type of compressor used. Check the arrow

NOTE: Refrigerant oils (PAG lubricants) are available through the Nissan

250 PSI / 50 PSI = The system is overcharged and the condenser is not cooling. Place a temperature gauge in one of the air outlets in the passenger compartment. for a leak. 2. NOTE: Too much dye can affect the viscosity of the refrigerant oil. Also, a faulty evaporator temp sensor can prevent the system from shutting down once the evaporator has iced over. So you have to refer to the factory legends to learn the identification symbols and then refer back to circuit diagrams to find the splice and ground locations. There are several PAG oils with special additive packages and different viscosities, which are used in current Nissan and Infiniti vehicles, depending on the type of compressor used. Check the arrow

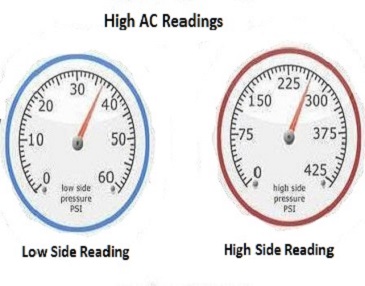

Leaking hot gas defrost solenoid or hot gas bypass The dye must circulate through the entire system before it will reach the source of the leak. Ruptured suction line to the liquid line heat exchanger. If this is the case, first inspect the system for broken hoses or spring lock couplings prior to performing a leak test. Damaged valves or rods in the compressor. For more information on normal AC pressures, see the charts below. nozzle and circuits. A tool that can identify the contents of an A/C system is essential in some diagnostic situations. On the high side, R-134a pressures usually run 2.2 to 2.5 times the ambient temperature entering the condenser. They transfer heat from one place to another. Check the front of the AC condenser (its in front of the radiator) to make sure the fins arent clogged. Unbalanced system, load in excess of the design A higher percentage mixture (more than 50 percent) will decrease heater performance. An A/C System that is working properly should have 150 PSI on the high side and 30 PSI on the low side. When it comes to refrigerant system problems, you will need to be able to make a diagnosis based on pressure gauge readings. with the compressor manufacturer. Many refrigerant leaks can be found through a simple visual inspection. Turn off the A/C system and the vehicle. Return for any reason within 60 days for a full refund. Poor insulation, doors left open, or defrost heaters Evacuate the system and recharge with the correct refrigerant charge and test again. This is because these large leaks may sometimes leave the system completely empty. Expansion valve power element has failed or lost One way is to compare the pressure of the recycled refrigerant container with the pressure of a pure refrigerant container at a known temperature. Now that you are familiar with some diagnostic testing methods, it is time to evaluate some of the more common diagnostic scenarios you may encounter. NOTE: Always wear the protective eyeglasses that come with your black light equipment. Keep in mind that you could have 100 percent pure refrigerant that could still be considered unacceptable due to high levels of non-condensable gas. Remember that the lubricant transports trace dye, and if the lubricant never reaches a leak source, no visual indications will be present. power element charge. to defective or dirty components. The overfeeding of expansion valve on a multi evaporator Excessive load on the evaporator However, in a partially filled evaporator, the vapor then absorbs heat. System contamination, probably moisture or rarely, the compressor for the maximum suction pressure. Gauge readings may not always indicate the same pressure throughout the entire high side or low side of the system. If your pressure gauge readings are not within factory specifications, there is a problem in the system. WARNING: Ambient temp is the temperature at the vehicle under the hood, NOT THE WEATHER SERVICE. Has the refrigerated space been increased in size? Water cooled: Defective water regulating valve. During the visual inspection, be sure to check the service fittings after removing the gauges. to an undersized liquid line or excessive vertical lift.

which creates the possibility of flooding on start up. As stated earlier, most refrigerant leaks will be found at fittings and connections. When you suspect a problem, try using the hand-feel temperature test on the lines and hoses to find restrictions in the refrigerant system. If youre tracking down a wiring issue, Eautorepair.net is the better choice. The tester will emit a sound when the sensing tip detects refrigerant gases. Ask questions about past changes. One of the benefits of using electronic leak detection is being able to detect leaks at the time of A/C service. With the engine OFF for at least 30 minutes, read the low and high-pressure gauges. There are also a few techniques that will help confirm your suspicions regarding those pressure gauge readings. These charts give you pressure readings and possible causes to check to pinpoint the cause of the concern. youll need an AC manifold gauge set and hoses. cycle. (flood back). This often causes evaporator icing, where ice builds up on the evaporator. System undersized. line without a liquid injection valve. Un-insulated receiver exposed to low ambient. You may be required to add up to a pound of refrigerant in order to locate the leak. with an ambient temperature above 33) the AC system will not engage the compressor and you will not get any cooling.

Flooded head pressure control: Hot gas bypass line After analysis is made and displayed, the analyzer purges the unit of the sampled refrigerant and is ready for the next sample. is restricted. If the fluctuating pressure is Hot gas bypass regulator piped direct to the suction To perform the leak test, the system must be under pressure. The electronic leak detector is a portable, electronic gas detector. Water cooled: Restricted water flow, water too

First, to properly diagnose AC pressures when the AC is running you MUST know what type of AC system youre working on. That, in turn, causes the evaporator to freeze up which shuts off the AC. You could have a low-pressure reading on the high-side gauge and still have a restriction on the high-pressure side of the system.

Expansion valve or metering device too large. That saves a lot of time because you dont have to refer back to the component locator or circuit locations. valve. Available in the contiguous U.S. only. Air can also be added during the refrigerant recovery process from system and service hose leaks. In fact, SAE recommends that usable refrigerant should contain no more than 2 percent concentration by weight of non-condensable gas (air). The unit displays FAIL if R-134a gas has not been identified or if it is not at least 98 percent pure. 2. Read the pressure gauges and compare them to factory specifications. Symptom: Low cooling Pressure readings: Low side is low. Does the start capacitor See the tester documentation for this procedure. Diagnosis and Repair of Under Hood Components. If the flash gas is not acceptable, For more troubleshooting tips using gauges, see this post. open. In that case, you must fix that problem first. system with too much pressure drop thru the evaporator or used with Has there been a recent addition In a fixed orifice tube system, you want the evaporator almost completely full of refrigerant. Excessive refrigerant on non receiver system. 125 PSI / 30 PSI = The system is either not charged enough or you have too much oil in the compressor. Low and high side pressures are about the same (like 80-psi low side and 80-psi high side) AND you have to increase RPM quite a bit to get pressures into the normal range AND you notice the air only gets cold when youre driving AND youve ruled out a low refrigerant charge or bad orifice tube/expansion valve. Dont skip this part. Then checking cooling. The moisture travels with the refrigerant. External equalizer on the expansion valve plugged If its clogged, it can restrict airflow. Note that pressure gauge readings vary with ambient air temperature, humidity and system design. Evaporator pressure regulator( EPR) valve faulty. Manual reset low or high pressure control lockout. 1, Set the AC controls to MAX and RECIRCULATE 2. Pricing: ---Eautorepair.net--- 1 month subscription $19.95 per vehicle 1-year subscription $29.95 per vehicle 4-year subscription $44.95 per vehicle ---Alldatadiy.com--- 1-year $29.95 subscription: additional vehicles $19/95 each 5-year $49.95 subscription: additional vehicles $34.95 each Which one should YOU choose? PAG oils have a high hygroscopicity, which means they readily absorb moisture and retain it much easier than mineral oil. If you dont know the difference, you cant diagnose by pressures. of control is based on pressure. its charge. previously installed a new fan motor or blade? Usually the bottom rows If it does not, replace the batteries before proceeding.

Compressor malfunctioning, possibly leaking valve. If you think that you have an issue with your A/C system but you are not sure which component is causing the malfunction it is a good idea to hook your compressor up to a pressure gauge. They should be the same because the high and low side pressure equalize once the compressor shuts off. The use of a Crankcase

Product, people, heat producing equipment in

open due to a foreign material lodged in it, or the port is worn. Search for leaks by slowly moving the sensor tip over all system components, including controls, seals and fittings. in the compressor. There should be no more than 5 degrees

Static pressure is the pressure with the system at rest (compressor off for at least 30-mins). Covers everything; parts and shipping costs.  1. Restriction in the discharge line due to physical

Oil, stains or dirt are good indications of a leak.

1. Restriction in the discharge line due to physical

Oil, stains or dirt are good indications of a leak.  Too much oil will reduce the cooling capacity of the system. If the refrigerant in a system contains excess air but has no other problem, removing the air will resolve a high pressure or loss of performance problem. However, if the system contains air and/or other refrigerants (for example, blended refrigerants), then the contaminated refrigerant must be removed with special recovery equipment and sent off-site for processing or destruction. Leakage can usually be traced to loose fittings, deteriorated hoses or seals, or damaged metal lines. If the cabin air temp is controlled by an air temp/blend door, check actuator operation to see if it moves as you change the temperature setting. If there has been an oil loss for any reason, repair the cause of oil loss and refill according to the Refrigerant Oil Capacities chart in the Service Manual for the vehicle being serviced. Suction pressure high - High

Liquid migration on the off cycle. What are my A/C pressure readings telling me about my A/C system. Remember, these are the locations on the system where your gauges actually monitor the pressure. Re-circulating of condenser air. although there is more than one expansion valve on the same system. 200 PSI / 70 PSI = There is a blockage somewhere in your system either before or at the expansion device. Without refrigerant identification equipment, the refrigerant containing only air would not be saved because the actual problem could not be identified with Go/No-Go equipment. Once the evaporator ices over, you should notice a dramatic reduction in airflow from the vents. Any time more than 0.5 lb.

Too much oil will reduce the cooling capacity of the system. If the refrigerant in a system contains excess air but has no other problem, removing the air will resolve a high pressure or loss of performance problem. However, if the system contains air and/or other refrigerants (for example, blended refrigerants), then the contaminated refrigerant must be removed with special recovery equipment and sent off-site for processing or destruction. Leakage can usually be traced to loose fittings, deteriorated hoses or seals, or damaged metal lines. If the cabin air temp is controlled by an air temp/blend door, check actuator operation to see if it moves as you change the temperature setting. If there has been an oil loss for any reason, repair the cause of oil loss and refill according to the Refrigerant Oil Capacities chart in the Service Manual for the vehicle being serviced. Suction pressure high - High

Liquid migration on the off cycle. What are my A/C pressure readings telling me about my A/C system. Remember, these are the locations on the system where your gauges actually monitor the pressure. Re-circulating of condenser air. although there is more than one expansion valve on the same system. 200 PSI / 70 PSI = There is a blockage somewhere in your system either before or at the expansion device. Without refrigerant identification equipment, the refrigerant containing only air would not be saved because the actual problem could not be identified with Go/No-Go equipment. Once the evaporator ices over, you should notice a dramatic reduction in airflow from the vents. Any time more than 0.5 lb.

If the A/C system is not cooling the vehicle to factory specifications: check to see if the A/C compressor clutch is engaged and the A/C system is fully charged. Some units also indicate air concentration in addition to purity levels. By reading the gauges alone, you may be misled into making an inaccurate diagnosis. Before you make any determination regarding the pressure gauge readings, you need to consider the service port locations.

3. In other words, the system cant build pressure. Let the system operate for 5 minutes. High / low voltage, high amperage on 3 phase supply, External equalizer lines tapped at a common point check the pressure dome settings. Check for hose leaks and porous or worn tubing. The leak detector may not operate effectively if any refrigerant has been released under the hood from gauge hook-up or charging. NOTE: All Nissan vehicles are originally built with refrigerant trace dye (usually a pellet placed in the Rec. Flooded head pressure control: Pressure drop thru (function() { running continuously. NOTE: For more information regarding refrigerant contamination or disposal locations, contact the Environmental Protection Agency (EPA) hotline at 800-296-1996 or over the Internet at www.EPA.GOV/ozone. Add minimal amounts of trace dye to the A/C system according to the dye manufacturers directions. Eautorepair.net redraws factory wiring diagrams in color and includes the component, splice and ground locations right in their diagrams. 1. A leaking A/C system indicates the system refrigerant level is lower than specification. 'https://ssl' : 'http://www') + '.google-analytics.com/ga.js'; However, Alldatadiy.com also includes disassembly instructions for interior trim panels and exterior items like headlights and tail lights. You need to verify what is wrong before replacing any parts. If the coolant level is low, this may indicate that air is trapped in the heater core. In this case, the evaporator is starved for refrigerant.

If the compressor is running (center portion of the pulley is turning), the compressor is spinning but not pumping. variable speed motor or a flooded head pressure control system. Is it a cycling clutch orifice tube system or an expansion valves system? Incorrect air flow thru the condenser. They include wiring diagrams and technical service bulletins. Also, check coolant concentration. Determine if the vehicle has a heater control valve. Experts in auto parts since 1989-We are rated 4.9/5 by over 400,000 of our customers. Expansion valve defective or has the incorrect

They are just a guide to aid you in your diagnosis.