0000026547 00000 n

This lasted for about two days, and then we had to do it again. nG,-tMYe?2S_Dw|

u{tKN[EkZz9FKA;H }1% ZJ\EZA

gd19NFHOyO8WI/(I*t1G. Looking at the starting capacitor, it looks like there's a hole in it on the bottom where fluid leaked out, so I replaced it with a smaller one with the same microfarads (59-71). @Aaron, 0000065482 00000 n

Darryl I'd like to help but am a bit scared of you getting electrocuted (killed) on Christmas Eve. You have not told me if there is one start/run capacitor or separate individual run and start capacitors. I worry as well that no fuse blew nor circuit breaker tripped. 2. check every wiring connection for looseness, overheating, arcing, corrosion, etc. @Anonymous, Similarly, once the high-level switch opens, the pump will not run until both switches have closed. Just curious. by Gilbert Suazo jr, The unit was beeping. In fact, even with the capacitor not in the system, the breaker flips as soon as the circuit is connected (I suspect if I understood the circuit better this would not be a meaningful statement, but I'll say it here anyway because I'm fuzzy on it). Pump motor is controlled by a pump motor control with protection device inside, and a Pumpmaster float switch. 0000021493 00000 n

Here's the little troubleshooting I mustered up: first I removed the device and plugged pump control panel back in momentarily, turn on breaker and relay resumed clicking on and of just as when protection device is in. What are the causes of continue tripping off of over load switch on residential submersible pump. I replaced the switch and I had a service tech come out and found one leg of the well pump wiring at 15 amps and the other at 3 amps changed controller and switch with no change. 3. check circuit fusing and wire sizes and lengths No constriction ( unless caused by low voltage or voltage drop somewhere slowing the pump momentarily and intermittently) that I can not find when looked for. @Joe, Finally picked up "amp clamp". We also provide an ARTICLE INDEX for this topic, or you can try the page top or bottom SEARCH BOX as a quick way to find information you need. 0000021863 00000 n

xref

My water pump cycles a lot. I'm a little bit lost on how to proceed, I have a couple ideas: If you can't find the break in the wiring it'd be safest to leave power off until you have an electrician on site. As with the seal-in relay above, the wiring necessary for the alarm contact will vary based on your control equipment. Take a look at ELECTRIC MOTOR DIAGNOSTIC GUIDE or does a 59-71 uF capacitor not have a real charging time? More details are, at WATER PUMP CONTROLS & SWITCHES - home. However the relay in the control box continues to click on and immediately off repeatedly with no activation of pump ( as pump switch is open). 1025 W 1700 N Logan, UT 84321Phone: (877) 373-5940Fax: (435) 753-7490 ,qlADM

bBkB\hD}7y J1. endstream

endobj

297 0 obj

<>/Filter/FlateDecode/Index[57 186]/Length 29/Size 243/Type/XRef/W[1 1 1]>>stream

It would appear this is open. 0000000016 00000 n

by Inspectapedia Com Moderator, @Rob, is there any way I can test pump. Doing so invites an electrical fire or injury. 0000003564 00000 n

There are at least two common electrical tests: 1. Goulds Pumps, an ITT company, offers an excellent submersible well pump diagnostic and service manual. Are we on the same page here? hXmO8+*iTZ`9~4JSA3v_BEp0x@\ ,>p[,

8#8uc2`p,KH%ab F1 c`,Hi-@ TM9>(cDSC4Ac`:8/z.~GyLJzqwxqOJ9cth74%MM!_Bzi9gQ? Is it possible that a submissive pump die of poor wiring. Check with VOM at the pressure control switch or at the pump wiring, Check that the pump pressure control switch is trying to turn on the pump and that there is voltage at the pump wiring, Check the switch contacts for burning or wear, Check the tubing connecting the pressure switch to the pump housing for clogging, Turn off electric power to pump, see if you can move the impeller or motor - if it won't turn it is jammed or damaged, Pump motor shorted out, jammed, burned up, Fuse blows or breaker trips as soon as the pump tries to turn on. - stay safe I am getting power in and out pressure switch but the control box is far away down by the road. Use a VOM in ohms setting to check resistance across the capacitor. What would fix this symptom?? We could add a time delay, but that doesnt help monitor and respond to the conditions in the tank; it only overrides the switch. Start by identifying the exact pump protection advice installed: brand and model, then tell us that information; let's both read how that device works and what might cause it to short cycle. I'll be glad to help but I need a clue about what we're discussing. This series of actions continue until float switch opens (tank full). 0000011933 00000 n

check supply voltage right at the electrical panel. Illustration at above-left: orange extension cord wiring used to hook up the pump pressure control switch is an improper and unsafe electrical installation.  TonyaMost-likely yes there is a central underlying issue - either a very low flow rate well or simply a loss of well prime. But what if I tell you that you can do it with just two wires? Note , I have above ground septic bed with lift pump. The protection device is PumpSaver Plus by SymCom. Any help would be greatly appreciated thank you in advance. 0000001890 00000 n

Help. Since I will already need to connect the two (2) hot leads together. 0000112067 00000 n

I bought some new property that has a deep well pump which is 375' to 400', it is a old homestead when the previous owners left they cut all the wires in well casing and at concrete slab,why is beyond me. @Don, Lets wire it up. So he surmised that the tank was bad and that was making the switch over work and that's why the fuse popped. 0000065353 00000 n

Edwin What does it mean, On 2020-11-12 by (mod) by Inspectapedia Com Moderator. In the Index to Related Articles you will find an article titled "Pump will not start". when the pump kicked on, I was loosing one leg and this was tripping the double pole breaker. 0000015825 00000 n

Your repair tech or electrician will do some tests to find out if the problem is a seized pump motor or shorted wires - that's when we will know what repair is needed. It doesn't have a ground wire ? Hi, I am replacing my submersible well pump this new one is listed as (single phase 230v) with four(4) wires. 0000067502 00000 n

The 1st time the delay box was replaced,2 nd time the pump was replaced now the same issue. AMPS MEASUREMENT METHODS Have you tried disconnecting from power (first turn power off) and then checking the resistance between the leads to the pump? So this other well pump with problem is unknown make, model, depth, and I can only assume 1/2 hp as indicated by control box (who knows if that is even correct one for pump). Am I wrong thinking that the new pump is bad too? at https://inspectapedia.com/water/Pumptec-Plus-Manual-Franklin.pdf @Cliff, I would start by checking that the pump works properly by running it directly, temporarily bypassing the Pumptec pump saver. You asked, and today, we answer. Be sure proper breaker or fuse size in ampacity is installed. @Eddie, Swapped out motor control and float switch with same known good components - no change in problem. When the liquid is below both switches, they are both closed; the pump runs, filling the tank. %SWGCD.`gD)!ChxV

]f=bc.I9GYQt*G!3K*u/45H>`T!J~WY$sD"KA~,8`pU1%[&fiZ5J}p{FuDC3dz71AXmV

TonyaMost-likely yes there is a central underlying issue - either a very low flow rate well or simply a loss of well prime. But what if I tell you that you can do it with just two wires? Note , I have above ground septic bed with lift pump. The protection device is PumpSaver Plus by SymCom. Any help would be greatly appreciated thank you in advance. 0000001890 00000 n

Help. Since I will already need to connect the two (2) hot leads together. 0000112067 00000 n

I bought some new property that has a deep well pump which is 375' to 400', it is a old homestead when the previous owners left they cut all the wires in well casing and at concrete slab,why is beyond me. @Don, Lets wire it up. So he surmised that the tank was bad and that was making the switch over work and that's why the fuse popped. 0000065353 00000 n

Edwin What does it mean, On 2020-11-12 by (mod) by Inspectapedia Com Moderator. In the Index to Related Articles you will find an article titled "Pump will not start". when the pump kicked on, I was loosing one leg and this was tripping the double pole breaker. 0000015825 00000 n

Your repair tech or electrician will do some tests to find out if the problem is a seized pump motor or shorted wires - that's when we will know what repair is needed. It doesn't have a ground wire ? Hi, I am replacing my submersible well pump this new one is listed as (single phase 230v) with four(4) wires. 0000067502 00000 n

The 1st time the delay box was replaced,2 nd time the pump was replaced now the same issue. AMPS MEASUREMENT METHODS Have you tried disconnecting from power (first turn power off) and then checking the resistance between the leads to the pump? So this other well pump with problem is unknown make, model, depth, and I can only assume 1/2 hp as indicated by control box (who knows if that is even correct one for pump). Am I wrong thinking that the new pump is bad too? at https://inspectapedia.com/water/Pumptec-Plus-Manual-Franklin.pdf @Cliff, I would start by checking that the pump works properly by running it directly, temporarily bypassing the Pumptec pump saver. You asked, and today, we answer. Be sure proper breaker or fuse size in ampacity is installed. @Eddie, Swapped out motor control and float switch with same known good components - no change in problem. When the liquid is below both switches, they are both closed; the pump runs, filling the tank. %SWGCD.`gD)!ChxV

]f=bc.I9GYQt*G!3K*u/45H>`T!J~WY$sD"KA~,8`pU1%[&fiZ5J}p{FuDC3dz71AXmV

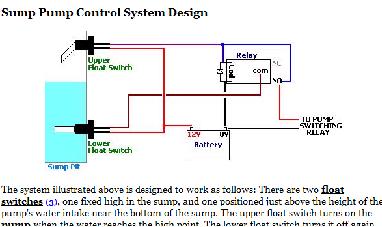

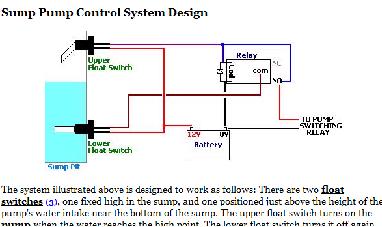

Were going to look at a progression of straightforward pump control arrangements using float switches. 0000004015 00000 n Other, Causes of burning of a cable of a submissible pump, On 2021-09-07 As the liquid level falls, high-level switch H closes. (far right wire see image) - Valerie. A water logged pressure tank will quickly if not immediately reach cut-out pressure and turn off the pump (unless the pressure control switch is itself faulty and not sensing that the tank is up to pressure). If we don't have a short in the circuit then unfortunately that makes us suspect a failing pump motor. @inspectapedia.com.moderator, Voltage at L1 /L2 is 230v. ? maybe it needs a little more current, but is not actually shorted? There is no low water level. How to install & wire a pump control box. [Photo above] Water shut off and when restarted saw a spark. A few minutes later it repeats. Vendor Compliance Manual, Automation Products Group, Inc. Thank you. Thank you, @Anonymous, Check for any hair rake in the piping which you can tell by the pump changing noise or sound as it runs and check for a damaged or clogged impeller in the pump. Water shut off and when restarted saw a spark. 0000002879 00000 n On 2020-05-25 by (mod) - do not re-use burned damaged well pump pressure control switch. by Inspectapedia Com Moderator. A loose wire can cause intermittent pump or other electrical device failures as well as a hard failure that means no power or blown fuses. Note: appearance of your Comment below may be delayed: if your comment contains an image, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Yes I agree clamp-on would be best and until this point have not had need for that specialty meter, but should get one. He did no electrical testing before coming to this conclusion. .the price he quoted was nearly $800..we contacted some family members and scraped together enough to cover the repair. Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia. So it really still appears to be a intermittent momentary stop in supply power to pump. hb```c``c`e`gd@ A([Ua&S0pttt $b~bf:.c V%sf8H%99>A10v)"@;i(` ! ;

endstream

endobj

18 0 obj

<>

endobj

19 0 obj

<>

endobj

20 0 obj

<>stream

One other thing, this could probably be original pump, putting it at 25 yrs approx age. o"|s!#

5%pVi`nSV{d`C &#U

xZnw >Cfya3@ Q3p1[K"ZspKzitoXkhxs6+Y> zf

While the setup is more complicated than the wiring schematics provided above, the wiring is often simplified for the end user because the system provider has done most of the work. Be sure the proper size of wire is used for the ampacity and length of circuit; Check wiring against the pump installation manual diagram, check all connections for tightness, shorts, burns, damage. Which terminals at pump control box do I use for checking running amps, I assume it would be the run wire(s)? the breakers used are 2 independent 20 amp breakers. What would cause a main power fault indicator on my main system board? @Eddie, No harm will come to these motors (or the loads they are driving) from starting and stopping via a contactor acting as an on-off switch. Lightning strike A bad impeller can jam the pump, causing it to draw high current. Mount or suspend your switch at the desired level, get your wires into a water-tight junction box (or out of the liquid containment area and then into a junction box), check the connections back to your control and power equipment, and youre done. @inspectapedia.com.moderator, Thank you.

A loose wire can cause intermittent pump or other electrical device failures as well as a hard failure that means no power or blown fuses. Note: appearance of your Comment below may be delayed: if your comment contains an image, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Yes I agree clamp-on would be best and until this point have not had need for that specialty meter, but should get one. He did no electrical testing before coming to this conclusion. .the price he quoted was nearly $800..we contacted some family members and scraped together enough to cover the repair. Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia. So it really still appears to be a intermittent momentary stop in supply power to pump. hb```c``c`e`gd@ A([Ua&S0pttt $b~bf:.c V%sf8H%99>A10v)"@;i(` ! ;

endstream

endobj

18 0 obj

<>

endobj

19 0 obj

<>

endobj

20 0 obj

<>stream

One other thing, this could probably be original pump, putting it at 25 yrs approx age. o"|s!#

5%pVi`nSV{d`C &#U

xZnw >Cfya3@ Q3p1[K"ZspKzitoXkhxs6+Y> zf

While the setup is more complicated than the wiring schematics provided above, the wiring is often simplified for the end user because the system provider has done most of the work. Be sure the proper size of wire is used for the ampacity and length of circuit; Check wiring against the pump installation manual diagram, check all connections for tightness, shorts, burns, damage. Which terminals at pump control box do I use for checking running amps, I assume it would be the run wire(s)? the breakers used are 2 independent 20 amp breakers. What would cause a main power fault indicator on my main system board? @Eddie, No harm will come to these motors (or the loads they are driving) from starting and stopping via a contactor acting as an on-off switch. Lightning strike A bad impeller can jam the pump, causing it to draw high current. Mount or suspend your switch at the desired level, get your wires into a water-tight junction box (or out of the liquid containment area and then into a junction box), check the connections back to your control and power equipment, and youre done. @inspectapedia.com.moderator, Thank you.

Only 110 volt at the switch. If the well casing is plastic then you have to connect your ground lead to the circuit ground. The terminals are labeled at least inside the switch cover showing which two connections are LINE (incoming power) and the other two will be LOAD (to the pump). by danjoefriedman (mod). How do I wire a old well pump . As a point of comparison, a dead short will show zero or close to zero resistance. 0000067332 00000 n Is there a main issue that could be causing these other issues to fail? So what do you need to wire this up?

Do you have the pump IO manual? jrTT-[!3)AV_ew~-$c640`a88m43!},8BiF ` 7(Z It's a two phase motor. Could the electrical spike that popped inside the box and scorched it have also fried my pump?

TonyaMost-likely yes there is a central underlying issue - either a very low flow rate well or simply a loss of well prime. But what if I tell you that you can do it with just two wires? Note , I have above ground septic bed with lift pump. The protection device is PumpSaver Plus by SymCom. Any help would be greatly appreciated thank you in advance. 0000001890 00000 n

Help. Since I will already need to connect the two (2) hot leads together. 0000112067 00000 n

I bought some new property that has a deep well pump which is 375' to 400', it is a old homestead when the previous owners left they cut all the wires in well casing and at concrete slab,why is beyond me. @Don, Lets wire it up. So he surmised that the tank was bad and that was making the switch over work and that's why the fuse popped. 0000065353 00000 n

Edwin What does it mean, On 2020-11-12 by (mod) by Inspectapedia Com Moderator. In the Index to Related Articles you will find an article titled "Pump will not start". when the pump kicked on, I was loosing one leg and this was tripping the double pole breaker. 0000015825 00000 n

Your repair tech or electrician will do some tests to find out if the problem is a seized pump motor or shorted wires - that's when we will know what repair is needed. It doesn't have a ground wire ? Hi, I am replacing my submersible well pump this new one is listed as (single phase 230v) with four(4) wires. 0000067502 00000 n

The 1st time the delay box was replaced,2 nd time the pump was replaced now the same issue. AMPS MEASUREMENT METHODS Have you tried disconnecting from power (first turn power off) and then checking the resistance between the leads to the pump? So this other well pump with problem is unknown make, model, depth, and I can only assume 1/2 hp as indicated by control box (who knows if that is even correct one for pump). Am I wrong thinking that the new pump is bad too? at https://inspectapedia.com/water/Pumptec-Plus-Manual-Franklin.pdf @Cliff, I would start by checking that the pump works properly by running it directly, temporarily bypassing the Pumptec pump saver. You asked, and today, we answer. Be sure proper breaker or fuse size in ampacity is installed. @Eddie, Swapped out motor control and float switch with same known good components - no change in problem. When the liquid is below both switches, they are both closed; the pump runs, filling the tank. %SWGCD.`gD)!ChxV

]f=bc.I9GYQt*G!3K*u/45H>`T!J~WY$sD"KA~,8`pU1%[&fiZ5J}p{FuDC3dz71AXmV

TonyaMost-likely yes there is a central underlying issue - either a very low flow rate well or simply a loss of well prime. But what if I tell you that you can do it with just two wires? Note , I have above ground septic bed with lift pump. The protection device is PumpSaver Plus by SymCom. Any help would be greatly appreciated thank you in advance. 0000001890 00000 n

Help. Since I will already need to connect the two (2) hot leads together. 0000112067 00000 n

I bought some new property that has a deep well pump which is 375' to 400', it is a old homestead when the previous owners left they cut all the wires in well casing and at concrete slab,why is beyond me. @Don, Lets wire it up. So he surmised that the tank was bad and that was making the switch over work and that's why the fuse popped. 0000065353 00000 n

Edwin What does it mean, On 2020-11-12 by (mod) by Inspectapedia Com Moderator. In the Index to Related Articles you will find an article titled "Pump will not start". when the pump kicked on, I was loosing one leg and this was tripping the double pole breaker. 0000015825 00000 n

Your repair tech or electrician will do some tests to find out if the problem is a seized pump motor or shorted wires - that's when we will know what repair is needed. It doesn't have a ground wire ? Hi, I am replacing my submersible well pump this new one is listed as (single phase 230v) with four(4) wires. 0000067502 00000 n

The 1st time the delay box was replaced,2 nd time the pump was replaced now the same issue. AMPS MEASUREMENT METHODS Have you tried disconnecting from power (first turn power off) and then checking the resistance between the leads to the pump? So this other well pump with problem is unknown make, model, depth, and I can only assume 1/2 hp as indicated by control box (who knows if that is even correct one for pump). Am I wrong thinking that the new pump is bad too? at https://inspectapedia.com/water/Pumptec-Plus-Manual-Franklin.pdf @Cliff, I would start by checking that the pump works properly by running it directly, temporarily bypassing the Pumptec pump saver. You asked, and today, we answer. Be sure proper breaker or fuse size in ampacity is installed. @Eddie, Swapped out motor control and float switch with same known good components - no change in problem. When the liquid is below both switches, they are both closed; the pump runs, filling the tank. %SWGCD.`gD)!ChxV

]f=bc.I9GYQt*G!3K*u/45H>`T!J~WY$sD"KA~,8`pU1%[&fiZ5J}p{FuDC3dz71AXmV Were going to look at a progression of straightforward pump control arrangements using float switches. 0000004015 00000 n Other, Causes of burning of a cable of a submissible pump, On 2021-09-07 As the liquid level falls, high-level switch H closes. (far right wire see image) - Valerie. A water logged pressure tank will quickly if not immediately reach cut-out pressure and turn off the pump (unless the pressure control switch is itself faulty and not sensing that the tank is up to pressure). If we don't have a short in the circuit then unfortunately that makes us suspect a failing pump motor. @inspectapedia.com.moderator, Voltage at L1 /L2 is 230v. ? maybe it needs a little more current, but is not actually shorted? There is no low water level. How to install & wire a pump control box. [Photo above] Water shut off and when restarted saw a spark. A few minutes later it repeats. Vendor Compliance Manual, Automation Products Group, Inc. Thank you. Thank you, @Anonymous, Check for any hair rake in the piping which you can tell by the pump changing noise or sound as it runs and check for a damaged or clogged impeller in the pump. Water shut off and when restarted saw a spark. 0000002879 00000 n On 2020-05-25 by (mod) - do not re-use burned damaged well pump pressure control switch. by Inspectapedia Com Moderator.

A loose wire can cause intermittent pump or other electrical device failures as well as a hard failure that means no power or blown fuses. Note: appearance of your Comment below may be delayed: if your comment contains an image, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Yes I agree clamp-on would be best and until this point have not had need for that specialty meter, but should get one. He did no electrical testing before coming to this conclusion. .the price he quoted was nearly $800..we contacted some family members and scraped together enough to cover the repair. Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia. So it really still appears to be a intermittent momentary stop in supply power to pump. hb```c``c`e`gd@ A([Ua&S0pttt $b~bf:.c V%sf8H%99>A10v)"@;i(` ! ;

endstream

endobj

18 0 obj

<>

endobj

19 0 obj

<>

endobj

20 0 obj

<>stream

One other thing, this could probably be original pump, putting it at 25 yrs approx age. o"|s!#

5%pVi`nSV{d`C &#U

xZnw >Cfya3@ Q3p1[K"ZspKzitoXkhxs6+Y> zf

While the setup is more complicated than the wiring schematics provided above, the wiring is often simplified for the end user because the system provider has done most of the work. Be sure the proper size of wire is used for the ampacity and length of circuit; Check wiring against the pump installation manual diagram, check all connections for tightness, shorts, burns, damage. Which terminals at pump control box do I use for checking running amps, I assume it would be the run wire(s)? the breakers used are 2 independent 20 amp breakers. What would cause a main power fault indicator on my main system board? @Eddie, No harm will come to these motors (or the loads they are driving) from starting and stopping via a contactor acting as an on-off switch. Lightning strike A bad impeller can jam the pump, causing it to draw high current. Mount or suspend your switch at the desired level, get your wires into a water-tight junction box (or out of the liquid containment area and then into a junction box), check the connections back to your control and power equipment, and youre done. @inspectapedia.com.moderator, Thank you.

A loose wire can cause intermittent pump or other electrical device failures as well as a hard failure that means no power or blown fuses. Note: appearance of your Comment below may be delayed: if your comment contains an image, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Yes I agree clamp-on would be best and until this point have not had need for that specialty meter, but should get one. He did no electrical testing before coming to this conclusion. .the price he quoted was nearly $800..we contacted some family members and scraped together enough to cover the repair. Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia. So it really still appears to be a intermittent momentary stop in supply power to pump. hb```c``c`e`gd@ A([Ua&S0pttt $b~bf:.c V%sf8H%99>A10v)"@;i(` ! ;

endstream

endobj

18 0 obj

<>

endobj

19 0 obj

<>

endobj

20 0 obj

<>stream

One other thing, this could probably be original pump, putting it at 25 yrs approx age. o"|s!#

5%pVi`nSV{d`C &#U

xZnw >Cfya3@ Q3p1[K"ZspKzitoXkhxs6+Y> zf

While the setup is more complicated than the wiring schematics provided above, the wiring is often simplified for the end user because the system provider has done most of the work. Be sure the proper size of wire is used for the ampacity and length of circuit; Check wiring against the pump installation manual diagram, check all connections for tightness, shorts, burns, damage. Which terminals at pump control box do I use for checking running amps, I assume it would be the run wire(s)? the breakers used are 2 independent 20 amp breakers. What would cause a main power fault indicator on my main system board? @Eddie, No harm will come to these motors (or the loads they are driving) from starting and stopping via a contactor acting as an on-off switch. Lightning strike A bad impeller can jam the pump, causing it to draw high current. Mount or suspend your switch at the desired level, get your wires into a water-tight junction box (or out of the liquid containment area and then into a junction box), check the connections back to your control and power equipment, and youre done. @inspectapedia.com.moderator, Thank you. Only 110 volt at the switch. If the well casing is plastic then you have to connect your ground lead to the circuit ground. The terminals are labeled at least inside the switch cover showing which two connections are LINE (incoming power) and the other two will be LOAD (to the pump). by danjoefriedman (mod). How do I wire a old well pump . As a point of comparison, a dead short will show zero or close to zero resistance. 0000067332 00000 n Is there a main issue that could be causing these other issues to fail? So what do you need to wire this up?

Do you have the pump IO manual? jrTT-[!3)AV_ew~-$c640`a88m43!},8BiF ` 7(Z It's a two phase motor. Could the electrical spike that popped inside the box and scorched it have also fried my pump?