Our systems come in kits for those interested in customizing their installation. When your assembly line is running smoothly and performing efficiently, your company can move faster and smarter.

These virtual drawings help visualize interaction points before your conveyor shows up to your site. Common automated conveyor systems are listed and described below: Consisting of a looped belt of metal or rubber linked sections, belt conveyors are some of the most common type of conveyor systems. Thomas Register and Each unit has at least two pulleys, one that operates under power and an idle one. The TAVA Systems line of conveyors is produced with the highest quality components. See 870-732-5191. Learn more about Bastian Solutions' Conveyor >. An escalator is an example of a chain-driven conveyor system. {{#each product.specData:i}}

Dont leave conveyor automation to chance. With hygiene system solutions you will be able to maintain the demanded level of hygiene for your industry. As the wheels turn, the chain advances. There are many benefits to applying Dorners assembly and industrial automation conveyor technology, such as: The assembly automation market has driven us to create machines that drive automation. Parque Industrial Nogales, 128 Jalan Permatang Damar Laut, Bayan Lepas 11960, 2022 Dorner Mfg. Looking to expand your greenhouse production operation?

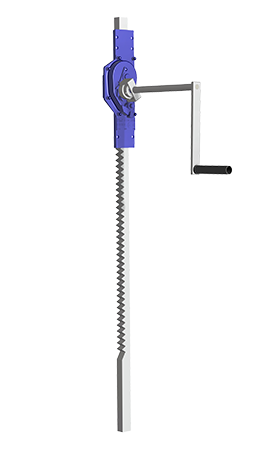

them on two or more lanes and conveys them toward Patented spring loadeddriveshaft connections. While conventional conveyor systems such as moving walkways and grocery store conveyors are straight, sometimes, the unit needs to turn to deliver the items to the proper location. For modern warehouses, manual transfer operations are unable to keep up with throughput levels required for speedy order fulfillment cost-efficiently. - Reinke and Schomann, Inc. Along with all the conveyor brands we integrate, we also design and manufacture best-in-class conveyor and ancillary conveyor products. What is the maximum weight of the products? 870-732-5050 Our automated conveyor systems solutions have been applied to: Technologies employed in our automated conveyor systems include: In addition to transporting and routing, Kraken offers value-added accessories for automated conveyor systems, which include: Kraken will work with your automated conveyor systems requirements. Without a subpoena, voluntary compliance on the part of your Internet Service Provider, or additional records from a third party, information stored or retrieved for this purpose alone cannot usually be used to identify you. Increasing manipulation speed between areas. In fact, here at Dorner, we set the industry standard for systems designed around unit handling automation challenges. A screw conveyor is a large screw that transports materials by turning. What is the dimensional data for each product? With this we gained many experience, which ensure us to provide solutions that are perfect for our customers needs. Different widths: 200 - 2500 mm Often used in the auto industry, a chain conveyor consists of a large chain fashioned in a loop around two pulley wheels. Even with the , Among the 10 companies honored in 2020 for utilizing technologies that will shape tomorrows supply chains, NextGen has recognized 6 , The e-commerce boom has increased the load on warehouses and distribution centers. Storing pending parts 10+ million models from leading OEMs, compatible with all major CAD software systems. Through the COVID-19 crisis, that focus is fueling our efforts to provide tools, methodologies, and recommendations to keep front-line workers in the warehouse safe while they keep our supply chains moving. The belt forms a closed loop around the pulleys so it can continually rotate. Dorner conveyors easily integrate with robots, workers and equipment. This system minimizes human error, lowers workplace risks and reduces labor costs among other benefits.

7 Reasons Why Warehouse Robots Beat Traditional Automation, Scaling up for peak fulfillment this season, Eight Warehousing Trends Continuing in 2022: What You Need to Know, The ultimate guide to warehouse order picking, Top 52 logistics conferences and events to attend in 2020. Slight Tlesto is a manual or automated air handling system. MSK Transtech pallet conveyors Learn More. -Central lubrication system for the cleated chain. Bastian Solutions will work with you to determine the optimal conveyor solutions, placement, and integration with other technologies to ensure that you achieve throughput and quality goals now and in the future.

-Manual width adjustment This may be done via a traditional flat conveyor system, spiral, incline, or through an overhead setup. Enter your email address below and we'll provide you with information you need to get you started. Typically, conveyor systems consist of a belt stretched across two or more pulleys. The design allows for movement of objects that are too heavy or too bulky for humans to carry by hand. Looking For Custom Solutions ? Conveyors are used because they are fairly easy to design and maintain, and the variety of conveyor systems available allows for them to fulfill different roles. These apparatuses still use a belt or chain and pulleys to move heavy items from one point to another.

Stacker cranes for boxes can operate in a variety of circuits, with straight sections, curves, slopes and even different levels.

Layout required only for the conveyor drive and absolutely no consumption for magnetic field generation contribute to significant energy savings. Flexible chain conveyors and pallets for product routing, control and inspection.

Youll also find conveyor systems in airports, where theyre used to transport luggage. Our engineers are available to talk to you about your project details. They are useful in helping to move bulky or heavy items from one point to another. All About Roller Conveyors - Types, Design and Uses, All About Screw Conveyors - Types, Design and Uses, All About Vertical Conveyors - Types, Design and Uses, All About Slat Conveyors - Types, Design and Uses, All About Pneumatic Conveyors - Types, Design, and Uses, All About Drag Conveyors - Types, Design, and Uses, All About Bucket Conveyors - Types, Design, and Uses, All About Overhead Conveyors - Types, Design, and Uses, All About Vibrating Conveyors - Types, Design, and Uses, All About Magnetic Conveyors - Types, Design and Uses, All About Vacuum Conveyors - Types, Design, and Uses, Top Conveyor Manufacturers and Suppliers in the USA, The Best Laptop for Automotive Technicians, According to 10,000 Customer Reviews, Top Battery Enclosure Manufacturers and Suppliers, Top Integrated Circuits Manufacturers in the USA and Internationally, The Best Raspberry Pi Starter Kit (for Beginners and Intermediates), According to 4,000+ Customer Reviews, The Best Tablet for Architects, According to 14,000+ Customer Reviews, Maintenance-free, No-adjustment Motor Brakes Help to Alleviate Worker Shortages, Easter Island's Statues Have Bodies Beneath the Surface, Molded Products Manufacturer Announces $5 Million Expansion, Apple's New Software Lets You Buy Gas from the Comfort of Your Car. The flow of material is smooth and optimized, so the time is effectively used. Privacy Statement and Numerous conveyor systems can are employed in standard applications. A conveyor more or less acts as a central nervous system for operations that receive, handle, store, distribute, manufacture or ship products. {{#i!=(product.specData.length-1)}} Our automated systems are proven to reduce costs while saving time and resources with proper configuration. Railings, Wall and Corner Impact Protection, Total Intralogistics and Material Handling Solutions, Euro Crate, Box, Euro Pallet Box and IBC Container Transporters. *Prices are pre-tax. You should simultaneously consider both product and process requirements. With our DTools configuration process, you can control each step of the design process from choosing materials to selecting a layout. Low maintenance. More complex conveyor systems may have additional rotors throughout the frame. Many ways to hold conveyors in place pictured are stands and monorail cart. Kraken also offers engineering and consultation services that assist process manufacturers in optimizing packaging line performance, efficiency, and reliability. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates. 50 expert warehouse automation tips and best practices. Bastian Solutions engineers use advanced design tools like AutoCAD, Solidworks and Navisworks to develop conveyor system designs quickly and accurately helping you get your system up and running sooner. Our goal is to fill gaps in the marketplace to ensure our customers exceed their systems throughput goals while reducing operational costs. As the screw turns, material follows the direction of revolution to the area of transportation. Automated conveyor systems are ergonomically designed for better comfort and productivity and are user friendly, which makes work easier for employees. The technical storage or access is required to create user profiles to send advertising, or to track the user on a website or across several websites for similar marketing purposes. In case of any questions about automated conveyor system or any other type of storage system, please do not hesitate to contact us, we will be happy to help you. At Kleenline, we understand the diverse and unique requirements of your products. How are the products being conveyed and in what orientation? Kraken designs and manufactures conveyor solutions of any size, from small belt conveyors for vial and gum packets to large pallet conveyor systems. - Roller conveyors & Accumulation conveyors 3850 Southland Drive For years, our Dorner conveyor experts have been developing and producing cutting-edge systems for assembly and industrial needs.

Washable stainless steel rail These units use an electric track inclined to pull the chairs up or down the mountainside. The modules: roller and axial wheels, ball planes, packing tables, frames, supports, couplings, guides adaptation, conveyor belts. Transfer speed short, rapid movement or slow, steady movement. 's Spiral Conveyors can mm/20 - 450 mm/20 - 450 mm

What is the average weight per foot of product? The number of products you need to transport per hour (or per minute) will determine conveyor length and speed.

Take control with our pallet systems and precision move technology in automation. From the beginning, we have focused on empowering associates with the right tools to get the job done. Company. Kraken Automation develops innovative, customized packaging automation technology, as well as turnkey automation solutions, based on over thirty years of industry experience. However, the costs saved by using a conveyor system usually defray maintenance costs. Maintenance can be as simple as replacing belts, oiling shafts, and cleaning out gears. As such, the type of item(s) to be moved will determine the design, dimensions and type of conveyor system to be installed. Totally stainless steel chassis The cutting and forming conveyor is designed for the automatic continuos process of the sponge, reducing any manual work and increasing the product output. 2022 6 River Systems, LLC. This also proves to be beneficial when working in a wet environment where the belt, on a traditional design, can stick to the bed making it difficult, if not impossible, to start the conveyor under full load. ico-arrow-default-right. These precision move pallet systems are flexible, accurate, versatile, and easy to use. Pallet conveyors are designed to manage heavy loads on pallets or skids. If you do not see what you are looking for, please contact us, as there are hundreds of products available. Website Last Modified July 30, 2022. {{#each pushedProductsPlacement5}}, With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation. line cutting machine is used for discharging outer tube.

Once project planning is complete, the next phase is system design and layout.

Screw Conveyor Flighting, courtesy of Reinke & Schomann. We use cookies to optimize our website and our service. If youre considering a conveyor system, consider your budget, the speed at which you need to complete your work, space and other constraints, and of course, your loading and unloading plans. The frames are made of aluminum, the components are made of stainless steel and the roller bed is made of high impact PVC. Our objective like yours is to convey product gently, without damage, while doggedly pursuing maximum throughput and zero loss. It can range from the hundreds of thousands of dollars to millions, depending on factors such as: Current estimates show that a Belt Curve AC and a Roller Curve AC conveyor cost approximately $5,243 and $2,686 per linear foot under the following assumptions: Note: This is just the upfront cost of the conveyor equipment. Maximum load: 50 kg - 100 kgSpeed: 25,000, 45,000, 60,000 mm/minEffective width: 600, 800 mm. REJECTION CONVEYORS Kraken Automation is SOLIDWORKS certified. Conveyor types generally fall into three classificationssortation, accumulation and transportwhich are outlined below, along with informationabout pallet conveyorand conveyor accessories. Our team of engineers is ready to help you achieve your goals. First off, an ideal conveyor system must be: Installing the wrong conveyor system will quickly undermine a warehouses operational efficiency, leading to higher cost and lower customer satisfaction, eventually stripping the business of its competitive advantage. Modular in design and able to handle a wide range of product dimensions, our conveyor has the flexibility to integrate seamlessly throughout your facility. However, conveyance systems can also be entirely mechanized and automated for the transportation of heavier materials and for interaction with automated production lines. Box Conveyor Systems More and more manufacturers of automated equipment are looking to conveyor belts as an integrated part of their systems and products. West Memphis, AR 72301, Call: To accommodate the surge in demand, distribution centers , Fast, flexible, powerful A new way to automate.

Also, certain kinds of conveyors are ideal for certain products. This extremely accurate product control allows Dorner conveyors to easily integrate with robots, workers and equipment. Maximum load: 20, 5 tSpeed: 6,000, 20,000 mm/min. Why warehouse conveyor systems are outdated Crocs' pop-up warehouse ready in time for peak, Warehouse Management, Automation & Fulfillment Blog, Reliable (parts and components engineered to last), Cost-effective (in terms of TCO, or total cost of ownership). This provides a low friction surface for the belt to run on which in turn uses less power, can handle more weight with less wear and tear on individual components.

The PCB is taken over fron the upstream system and handed over to the downstream system. Maximum load: 1,500 kgSpeed: 12,000 mm/min. The use of a firm support unit keeps the belt taut and running efficiently. -Automatic tensioning station for the cleated chain

Get a free consultation. During this phase, our consultants: With the design in place, Bastian Solutions engineers help: Learn more about conveyor system design & integration >. Product orientation must items be positioned in a particular way (for easy scanning of barcodes, transfer, etc.)? As they can be inclined to span multiple levels, they make it simpler to move items up and down floors, a task that, when performed manually by humans, causes physical strain. Maximum load: 25, 50 kgSpeed: 15, 22 mm/min.  The outer tube, inner tube and feed pipe are welded by using CNC automatic welder so as to ensure the coaxiality of outer tube and inner tube as well as the welding KCB belt conveyors to provide our customers with fully functional and versatile belt conveyor systems.

the automatic palletization system positioned downstream. Other examples include escalators and ski lifts. This can be inserted into the EdgeRacer when needed. Global Material Handling System Integrators, Conveyor Systems & Equipment | Material Handling Technologies, Our Culture - Diversity, Equity & Inclusion, render some of our systems in 3D and generate simulations, Product or material traffic rate and routing, In-line equipment ID scanners, scales, print & apply label applicators, Automation technology and system integration. to facilitate this. Products with a smaller footprint may require a powered transfer, while larger and longer products may need gravity rollers. A large plastic chain conveyor is best used for transferring plastic-footed pallets, while a chain-driven roller conveyor is best suited for wooden pallets. Corp.

Transport conveyors move products, cases, totes or pallets from one point to another. Find and evaluate OEMs, Custom Manufacturers, Service Companies and Distributors. The basic premise of our conveyor design is to run the belt across a bed of rollers rather than dragging it across a deck. Dorners conveyors are designed to move product to the exact location, at the exact time and in the exact position it needs to be for the next phase of the production line. There are many types of conveyor systems, including: Each type of conveyor serves a specific purpose. Copyright 2022. -Solid steel construction in painted or stainless-steel version

The power transfer from the drive section to the add-on sections is done via drive shaft for efficient transfer of power.

The outer tube, inner tube and feed pipe are welded by using CNC automatic welder so as to ensure the coaxiality of outer tube and inner tube as well as the welding KCB belt conveyors to provide our customers with fully functional and versatile belt conveyor systems.

the automatic palletization system positioned downstream. Other examples include escalators and ski lifts. This can be inserted into the EdgeRacer when needed. Global Material Handling System Integrators, Conveyor Systems & Equipment | Material Handling Technologies, Our Culture - Diversity, Equity & Inclusion, render some of our systems in 3D and generate simulations, Product or material traffic rate and routing, In-line equipment ID scanners, scales, print & apply label applicators, Automation technology and system integration. to facilitate this. Products with a smaller footprint may require a powered transfer, while larger and longer products may need gravity rollers. A large plastic chain conveyor is best used for transferring plastic-footed pallets, while a chain-driven roller conveyor is best suited for wooden pallets. Corp.

Transport conveyors move products, cases, totes or pallets from one point to another. Find and evaluate OEMs, Custom Manufacturers, Service Companies and Distributors. The basic premise of our conveyor design is to run the belt across a bed of rollers rather than dragging it across a deck. Dorners conveyors are designed to move product to the exact location, at the exact time and in the exact position it needs to be for the next phase of the production line. There are many types of conveyor systems, including: Each type of conveyor serves a specific purpose. Copyright 2022. -Solid steel construction in painted or stainless-steel version

The power transfer from the drive section to the add-on sections is done via drive shaft for efficient transfer of power.

How to build an automated warehouse system: which new technologies do you need and why? Whats the Difference Between Helicoid Flighting and Sectional Flights? The technical storage or access is necessary for the legitimate purpose of storing preferences that are not requested by the subscriber or user. Possibility to integrate an automatic loader / unloader

Carts for transportation belts and for storage. All Rights Reserved. Thanks to the wide range of Intralox plastic modular chain, M.H. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. This is useful to combine or separate PCBs production flows (i.e. The drive unit allows the system to move. These are most often used to gather and line up cartons or unit loads for further processing like sorting, wrapping, palletizing, strapping, or other processes. California Do Not Track Notice. Transporting and routing pouches and bags (up to 60 lbs weights), Transporting and routing cans, trays, and cartons, Transporting and routing unwrapped and wrapped slip sheeted loads and pallets, Standard or sanitary (to USDA standards) belt or rope conveyors, Standard or sanitary (to USDA standards) chain conveyors, Magnetic, vacuum assist, or air cushion conveyors, Standard or sanitary live roller conveyors, Product analysis and reject systems (bar code SKU validation, open flap check, food metal detectors), Product identification and labelling (UV based ID tagging, adhesive/ink jet/laser labelling), Product diversion with speeds of up to 250 PPM.