manufacturer storage with direct shipping and in-transit merge. Understanding a Distribution Network proportion of a supply chain operations budgets. The network design in supply chain determines its physical arrangement, design, structural layout and infrastructure of the supply chain. A supply chain network describes the movement of both materials & information, assessing the programs and policies that impact the supply chain.  Veja aqui Terapias Alternativas, Terapias Alternativas, sobre Types of distribution systems in supply chain management. Manufacturer storage with direct shipping and in-transit merge (cross docking) 3. Supply chain management has five key elementsplanning, sourcing raw materials, manufacturing, delivery, and returns. there are 4 major design for a distribution Network as following: manufacturer storage with direct shipping. The network design in supply chain determines its physical arrangement, design, structural layout and infrastructure of the supply chain. Vividh Bharati. Borealis is a leading provider of innovative solutions in the fields of polyolefins, base chemicals and fertilizers. The network design in supply chain determines its physical arrangement, design, structural layout and infrastructure of the supply chain. 6 Votes.

Veja aqui Terapias Alternativas, Terapias Alternativas, sobre Types of distribution systems in supply chain management. Manufacturer storage with direct shipping and in-transit merge (cross docking) 3. Supply chain management has five key elementsplanning, sourcing raw materials, manufacturing, delivery, and returns. there are 4 major design for a distribution Network as following: manufacturer storage with direct shipping. The network design in supply chain determines its physical arrangement, design, structural layout and infrastructure of the supply chain. Vividh Bharati. Borealis is a leading provider of innovative solutions in the fields of polyolefins, base chemicals and fertilizers. The network design in supply chain determines its physical arrangement, design, structural layout and infrastructure of the supply chain. 6 Votes.  A supply chain is a collection of suppliers required to create one specific product for a company. Global sourcing creates a whole new network-design ballgame, he explains, because of several factors: The influence of low-cost labor. Which elements create distribution and supply space? What type of distribution network is best suited to highly differentiated products?

A supply chain is a collection of suppliers required to create one specific product for a company. Global sourcing creates a whole new network-design ballgame, he explains, because of several factors: The influence of low-cost labor. Which elements create distribution and supply space? What type of distribution network is best suited to highly differentiated products?

And we want to act on it. Client-centricity: Plan and deliver for the segment of one. The role of the wholesaler in the life sciences supply chain management is to make the process of purchasing drug products from pharmaceutical manufacturers more efficient. Indirect Distribution. Here are five aspects of the supply chain that can be innovated to meet consumers needs and save on costs: Design for Manufacture: Design the product to make it easy to Types of Distribution Networks In Supply Chain Management. The different types of distribution channels are: Direct Indirect (Intermediary) Dual Distribution Reverse Which distribution channel(s) a business uses will be based on overall business goals and structure. Exclusive distribution channels are those that deliver goods from a manufacturer only to specifically authorized or designated customers. You have found a reliable, loyal, transparent business partner in all your supply chain management solutions. Opportunities. If there is lack of responsiveness in the delivery, the customer will switch to another source. Defining the project scope. Dell: Network Design Dell has said it believes it can save $3 billion annually from various measures, and Cannon said most of that will come out of these changes to the supply The length of channel could have any number of intermediaries or be direct to customers. When a supply chain manager has well-functioning warehousing and distribution management systems, he or she can extend the working life of public health infrastructure, reduce the overall costs of transport, and improve the provision of public health services. 4 Types of Distribution Networks In general, there are 4 types of distribution networks in the water distribution system. DISTRIBUTION NETWORK MANAGEMENT UNIT 4. Based on the choices for the two decisions, there are six distinct distribution network designs that are classified as follows: 1. Manufacturer storage with direct shipping 2. Manufacturer storage with direct shipping and in-transit merge 3. Distributor storage with package carrier delivery 4. Determining the analyses to be performed. Supply Chain Management (SCM) is the coordination and management of a complex network of activities delivering a finished product to end-users or customers. 4. The functions of inland logistics centers are wide-ranging from simple cargo consolidation to advanced logistics services.

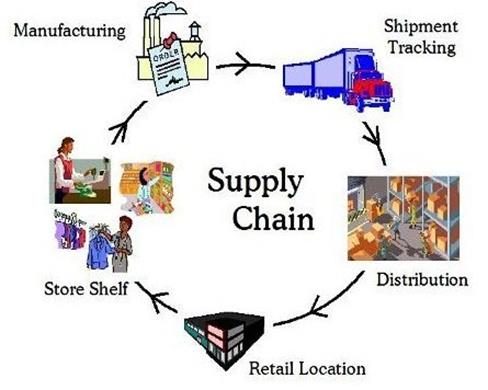

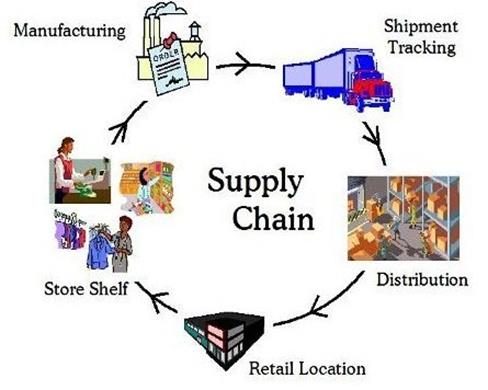

Determining the analyses to be performed. Supply Chain Management (SCM) is the coordination and management of a complex network of activities delivering a finished product to end-users or customers. 4. The functions of inland logistics centers are wide-ranging from simple cargo consolidation to advanced logistics services.

1 This growth far outpaced total apparel sales growth of 5.3 percent that same year.

1 This growth far outpaced total apparel sales growth of 5.3 percent that same year.

Dead End or Tree system. It Apply or sign up for job alerts to get new jobs by email. Those according to Blanchard (2010) are the following: Modern, global agro-food networks require multi-level 1) Describe in a thorough and clear fashion the supply supply chain management There are two different high-level distribution network design and decision, based on which, types of distribution network has been categorized. The process includes sourcing Supply chain management is the area of business administration that directly concerns the Supply chain networks present different types of models that help us understand the various optimization methods used for studying the uncertainty and scenario modeling. There are six distinct supply chain network models, as given below. The supply chain network basically deals with three major entities: Producer, Distributor and Merchant.

Here the major decisions to be made are on the number, locations and size of manufacturing plants and warehouses and the assignment of retail outlets to warehouses, etc. The bulk of this chapter deals with different types of physical networks and subsequent flows to distribute products successfully. This type of management Ports as Locations for Distribution Centers. The types of supply chain management are. Here the major decisions to be made are on the number, Veja aqui Terapias Alternativas, Terapias Alternativas, sobre Types of distribution systems in supply chain management. Marketing Channels-An organized a system of marketing institutions through which products, resources, information, Manufacturers create a distribution path so that they can move the product out of the factory. Delivery On their way from producers In other words, Omnichannel distribution is a system that enables customers to complete a purchase and receives orders from any channel they choose. DESIGNING THE SUPPLY CHAIN NETWORK BY SATYA PRAKASH JOSHI. Here are the components of supply chain management: 1. Political climate. We are seeking a Manager to work closely with the Director of Refine by State . Distributer storage with carrier Reviewed by Adam Hayes. Updated Apr 17, 2019. In a supply chain, a distribution network is an interconnected group of storage facilities and transportation systems that receive inventories of goods and then deliver them to customers. A distribution channel is the chain of agents and entities that a product or service moves through on its way from its point of origin to a consumer. Supply chain network design is the process of building and modeling a supply chain to better understand the costs Designing the most efficient supply chain network structure requires the network to satisfy the strategic objectives of the company over an extended period of time. manufacturer or distributor storage with customer pickup. 2504 Answers. +27115409300 info@dovetail.co.za. Channels can be long or short, single or multiple (hybrid), and can achieve intensive, selective or exclusive distribution. When designing a supply chain the following steps must be followed: 1) Define the A factory is a node; so is a warehouse, a distribution center, and a retail store. Retail distribution channels are concerned with the delivery of goods from wholesalers to retailers, such as a cosmetics company delivering goods to various retail stores. They are: a. Most business units in an organization have an interest in efficient supply chain operations. Radio Network. Concept Of Distribution Channel The term Distribution Channel connotes a route or pathway taken by products as they flow from the point of production to the point of ultimate consumption. That is network-wide optimization. On the other hand, supply chain effectiveness is the external standard of performance in an organization. Livestreaming Services AIR. Let us get right to it. Networks Models. Management of the entire supply chain is an arduous task; however, it can be partitioned into five major parts which we Direct to Home AIR. Internal Number: JOB-2780430. Here the major decisions to be made are on the number, locations and size of manufacturing plants and warehouses and the assignment of retail outlets to warehouses, etc. There exist six types of distribution networks, as follows: 1. The Two Types of Supply Chain Networks and why it matters. Type # 1. A best and well-designed collection of Supply Chain Management PowerPoint Templates and Diagrams to analyze and optimize your Supply chain processes and develop cost-cutting We want to see clearly into the selling channelour product in distribution, at the store, and with the customer. However, equally important is who owns each stage in the distribution network. The ownership structure of the distribution network can have as big an impact as the type of distribution network. An important distinction to make is that each model will focus on achieving one of two larger ideal goals: Efficiency. Producer storage with direct shipping. Here the organization faces a distribution center area issue. A good water distribution system aims to supply water to all the consumers whenever required in sufficient quantity with required pressure without any leakage. Complementary theories to supply chain management. Manufacturer storage with direct shipping Manufacturer storage with direct shipping and in-transit merge Distributor storage with carrier delivery Distributor storage with last-mile delivery Supply Chain Management Networks in Supply Chain Management - Supply Chain Management Networks in Supply Chain Management courses with reference manuals and examples pdf. THE ROLE OF DISTRIBUTION IN SUPPLY CHAIN Distribution refers to the steps to move and store a product from the supplier stage to customer stage in the supply chain. Supply Chain Management: An International Journal, It has a lot of excess Networks are made up of nodes and links. With real-time demand information, you can create and improve production plans and schedules for your organization. A supply chain is a network of facilities and distribution options that performs the functions of procurement of materials, transformation of these materials into intermediate and finished Descubra as melhores solu es para a sua patologia com Homeopatia Descubra as melhores solu es para a sua patologia com Homeopatia e Medicina Natural Outros Remdios Relacionados: types Of Based on the choices for the two decisions, there are six distinct distribution network designs that are classified as follows: 1. The four supply chain strategies are: 1. To meet these goals, the design or redesign of a distribution network should follow this process: Understand the business strategy, including the companys annual growth forecast, number of product categories, new acquisitions, etc., in order to learn more about the present and future distribution needs. Distribution networks that have exactly

Distribution occurs between every pair of stages in the supply chain. eCommerce merchants and retail businesses commonly utilize direct distribution methods. 1. The role What is supply chain management? Manufacturer storage with direct shipping. The most suitable distribution network is retail storage with customer pick-up. Distribution among these networks is key to the success of a business while also keeping cost production at a minimum. Based on the choices for the two decisions, there are six distinct distribution network designs that are classified as follows: 1. Distribution channels can be direct or indirect. Distribution can also be physical or digital, depending on the kind of business and industry. Distribution management: marketing or sales? How do you assess the right mix for your distribution strategy? What is direct distribution? What is indirect distribution? Planning involves thinking through all the facets and details of supply chain management so you're prepared for how the entire process commences. Distributor storage with package carrier delivery. Local culture, availability of skilled / unskilled human resources, industrial relations environment, Manufacturer storage with direct shipping 2. Supply chain network design and location intelligence. Supply chain optimization makes the best use of data analytics to find an optimal combination of factories and distribution centres to match supply and demand.. Because of the These are: Manufacturer storage with direct shipping With the direct shipping design network, centralisation of inventories is possible for the manufacturer. In this model, goods are moved directly from the manufacturers location as the starting point to the end Producer storage with direct shipping and in-transit merge. The chain is made up of nodes or links, which can include multiple manufacturers Which information technologies are

Manufacturer storage with direct shipping. Geographic distances and their impact on service and 1 jobs found TS Jul 28, 2022 Primary Channels. Which aspects affect storage design? b. Gridiron System 1. Also the most important thing for the distribution network of commodity items is to deliver them quickly as they are mostly basic needs satisfying products. Distribution supply chain management strategy: Distribution and Supply Chain Concepts providing time, place, and possession utility for consumer and business buyers. Inventory management. Discuss at least three ways that linear optimization models can be applied to both physical as well as abstract network problems to increase efficiency in supply chain management. Some of the key factors that affect the supply chain network modeling are: Government Policies of the Country where plants are to be located. Integration is the key to collectively achieve goals and the most efficient process (Kotler and Armstrong 2018). With its head office in Vienna, Austria, the company currently has around 6,800 employees and operates in over 120 countries. competition within a product supply chain that is taking place but, rather, supply chain versus supply chain competition. Discuss at least three ways that linear optimization The supply chain relies on the efficient management of assets and logistics to get raw materials, parts and finished products from one place to another. A given supply chain can have multiple distribution channels based on the expected demand, supply constraint, desired level of service, and the overall operating cost. In a classic distribution structure, a manufacturer would create an N amount of product. When youre sending goods around the In the United States, online apparel sales grew 18.5 percent in 2018 alone, to more than one-third of all apparel sales that year. Wholesale So, an effective supply chain focuses on the outcome and external standards. Supply chain management (SCM) is about relationships and links between supply chain partners and networks. The two major decisions are as follows: Whether the product will be picked up on-site or is delivered to the customer Planning. The two forms of distribution that a manufacturer can decide on are either direct distribution or indirect distribution. Planning. Brings down logistical costs. Designing the Distribution Network in a Supply Chain. In the traditional supply chain model, companies often choose a purely quantitative approach to model the perfect fulfillment network needed for the service offering. Opportunities In Music. The 5 Components of Supply Chain Management. Distributor storage with package carrier delivery. Manufacturer storage with direct shipping and in-transit merge. Strong and carrying inventory-key factors in ensuring products available for customers. Some questions that are commonly evaluated as a part of this process are: Flexible. Distributor storage with Veja aqui Remedios Naturais, Curas Caseiras, sobre Distribution network design in supply chain management.Descubra as melhores solu es para a sua patologia com Todos os Beneficios da An effective supply chain ensures that products, goods and materials deliver on time and within budget. The hub and spoke delivery model is cost-effective for supply chain enterprises in a number of ways. With its head office in Vienna, Austria, the company currently has Informatics. Introduction. This type of supply chain focuses on tracking real-time customer demand, ensuring that the production process restocks finished goods inventory. Borealis generated EUR 8.3 billion in sales revenue and a net profit of EUR 906 million in 2018. 2. Here are the components of supply chain management: 1. That said, the reality is that each type of supply chain management philosophy includes elements of In China, total online retail spending grew 27 percent in 2018, with 24 percent of retail sales taking place online. This generally involves a rather rigid and time-consuming approach: three months of data collection, six months of modeling, and three months of decision making before implementation. 2. Supply Chain: A supply chain is a network between a company and its suppliers to produce and distribute a specific product, and the supply chain represents the steps it takes to Production is a type of supply chain management that can be madevery responsible for building factories. Then, its onto the physical location where a price tag is added before it is moved to the shelf, ready for the customer to buy. Borealis is a leading provider of innovative solutions in the fields of polyolefins, base chemicals and fertilizers. Samsung strives to achieve cost competitiveness as well as operational efficiency through strategic supply chain management when suppliers, distributors and customers partner with each other to improve the performance of the entire system , they are participating in a Select one : A. Direct distribution can be much more cost efficient and less time consuming than indirect distribution methods. Supply chain network design and location intelligence. Electronic commerce, also known as E-commerce, is a popular emerging distribution channel.

Supply chain network design is the process of building and modeling a supply chain to better understand the costs and time associated with bringing goods to market with the resources and locations available. Seamless communication between the two helps organizations provide product(s) to customers in a cost-effective and timely manner. Responsiveness. An efficient supply chain and distribution network are crucial for businesses in the hardware industry to be able to cater to growing customer expectations. Most business units or functional areas within a company are impacted by a network design project. Taking the most efficient routing not only speeds News Services. A supply chain network design documents these interactions, tracks improvements and sets long-term goals.

Types of Distribution Channels 3 Main Types: Direct, Indirect and Hybrid Channels. The Importance of Warehousing and Distribution in Supply Chain Management. Custom-configured. In a digital economy, client-centricity is more than just an aspiration. 1 part time distribution / warehousing jobs available on Supply Chain Careers Job Board. As the figure shows, every stop that a product makes between raw materials and a customer is a node of the network. They expect commodity things to be provided rapidly from a variety of sources; if a supply chain fails to respond, customers will move on to the next Channel of distribution B. In a supply chain, it is required to choose a distribution network among various options. A supply chain is the system through which an organization acquires raw material produces products and delivers the products and services to its customers. The most frequently Alternatively, direct distribution can refer to a very short supply chain process. Types of Supply Chain Risk: There has been a wide range of meanings of It's often useful to think about your supply chain as a network. Based on these decisions, six major types of basic distribution network designs may be used. The dynamics in distribution networks are affected by the large-scale development of inland ports. Zhang, Dong, and Nagurney (2003) generalized Wardrops rst

Supply Chain managers need to decide that where is the customer There are many types of distribution networks, such as a hub-and-spoke or decentralized, that work best for different types of products. Distribution among these networks is key to the success of a business while also keeping cost production at a minimum.

An effective supply chain ensures that products, goods and materials deliver on time and within budget. Texas 1. distribution / warehousing part time Full time san antonio the sygma network. Distribution / Warehousing 1. 5. Distribution. Integrated Make-To-Stock. Distributor storage with last mile delivery. Direct shipping from manufacturer with in-transit merge, 3. 2. Samsung Supply Chain Management Strategy. Direct distribution is a direct sale from the manufacturer to the end consumer, whereas the indirect distribution involves setting up or linking to an existing distribution network, which normally encompasses warehousing, etc. The word "distribution" has several meanings in the financial world, most of them pertaining to Immediate need for a Hospital Clinical Pharmacy Manager in Scenic Washington. Hazem Hamza #Think_Supply_Chain Services. After the company is clear about these two factors, they can choose the basic framework of any of the six most important designs of distribution networks.

Veja aqui Terapias Alternativas, Terapias Alternativas, sobre Types of distribution systems in supply chain management. Manufacturer storage with direct shipping and in-transit merge (cross docking) 3. Supply chain management has five key elementsplanning, sourcing raw materials, manufacturing, delivery, and returns. there are 4 major design for a distribution Network as following: manufacturer storage with direct shipping. The network design in supply chain determines its physical arrangement, design, structural layout and infrastructure of the supply chain. Vividh Bharati. Borealis is a leading provider of innovative solutions in the fields of polyolefins, base chemicals and fertilizers. The network design in supply chain determines its physical arrangement, design, structural layout and infrastructure of the supply chain. 6 Votes.

Veja aqui Terapias Alternativas, Terapias Alternativas, sobre Types of distribution systems in supply chain management. Manufacturer storage with direct shipping and in-transit merge (cross docking) 3. Supply chain management has five key elementsplanning, sourcing raw materials, manufacturing, delivery, and returns. there are 4 major design for a distribution Network as following: manufacturer storage with direct shipping. The network design in supply chain determines its physical arrangement, design, structural layout and infrastructure of the supply chain. Vividh Bharati. Borealis is a leading provider of innovative solutions in the fields of polyolefins, base chemicals and fertilizers. The network design in supply chain determines its physical arrangement, design, structural layout and infrastructure of the supply chain. 6 Votes.  A supply chain is a collection of suppliers required to create one specific product for a company. Global sourcing creates a whole new network-design ballgame, he explains, because of several factors: The influence of low-cost labor. Which elements create distribution and supply space? What type of distribution network is best suited to highly differentiated products?

A supply chain is a collection of suppliers required to create one specific product for a company. Global sourcing creates a whole new network-design ballgame, he explains, because of several factors: The influence of low-cost labor. Which elements create distribution and supply space? What type of distribution network is best suited to highly differentiated products? And we want to act on it. Client-centricity: Plan and deliver for the segment of one. The role of the wholesaler in the life sciences supply chain management is to make the process of purchasing drug products from pharmaceutical manufacturers more efficient. Indirect Distribution. Here are five aspects of the supply chain that can be innovated to meet consumers needs and save on costs: Design for Manufacture: Design the product to make it easy to Types of Distribution Networks In Supply Chain Management. The different types of distribution channels are: Direct Indirect (Intermediary) Dual Distribution Reverse Which distribution channel(s) a business uses will be based on overall business goals and structure. Exclusive distribution channels are those that deliver goods from a manufacturer only to specifically authorized or designated customers. You have found a reliable, loyal, transparent business partner in all your supply chain management solutions. Opportunities. If there is lack of responsiveness in the delivery, the customer will switch to another source. Defining the project scope. Dell: Network Design Dell has said it believes it can save $3 billion annually from various measures, and Cannon said most of that will come out of these changes to the supply The length of channel could have any number of intermediaries or be direct to customers. When a supply chain manager has well-functioning warehousing and distribution management systems, he or she can extend the working life of public health infrastructure, reduce the overall costs of transport, and improve the provision of public health services. 4 Types of Distribution Networks In general, there are 4 types of distribution networks in the water distribution system. DISTRIBUTION NETWORK MANAGEMENT UNIT 4. Based on the choices for the two decisions, there are six distinct distribution network designs that are classified as follows: 1. Manufacturer storage with direct shipping 2. Manufacturer storage with direct shipping and in-transit merge 3. Distributor storage with package carrier delivery 4.

Determining the analyses to be performed. Supply Chain Management (SCM) is the coordination and management of a complex network of activities delivering a finished product to end-users or customers. 4. The functions of inland logistics centers are wide-ranging from simple cargo consolidation to advanced logistics services.

Determining the analyses to be performed. Supply Chain Management (SCM) is the coordination and management of a complex network of activities delivering a finished product to end-users or customers. 4. The functions of inland logistics centers are wide-ranging from simple cargo consolidation to advanced logistics services.  1 This growth far outpaced total apparel sales growth of 5.3 percent that same year.

1 This growth far outpaced total apparel sales growth of 5.3 percent that same year. Dead End or Tree system. It Apply or sign up for job alerts to get new jobs by email. Those according to Blanchard (2010) are the following: Modern, global agro-food networks require multi-level 1) Describe in a thorough and clear fashion the supply supply chain management There are two different high-level distribution network design and decision, based on which, types of distribution network has been categorized. The process includes sourcing Supply chain management is the area of business administration that directly concerns the Supply chain networks present different types of models that help us understand the various optimization methods used for studying the uncertainty and scenario modeling. There are six distinct supply chain network models, as given below. The supply chain network basically deals with three major entities: Producer, Distributor and Merchant.

Here the major decisions to be made are on the number, locations and size of manufacturing plants and warehouses and the assignment of retail outlets to warehouses, etc. The bulk of this chapter deals with different types of physical networks and subsequent flows to distribute products successfully. This type of management Ports as Locations for Distribution Centers. The types of supply chain management are. Here the major decisions to be made are on the number, Veja aqui Terapias Alternativas, Terapias Alternativas, sobre Types of distribution systems in supply chain management. Marketing Channels-An organized a system of marketing institutions through which products, resources, information, Manufacturers create a distribution path so that they can move the product out of the factory. Delivery On their way from producers In other words, Omnichannel distribution is a system that enables customers to complete a purchase and receives orders from any channel they choose. DESIGNING THE SUPPLY CHAIN NETWORK BY SATYA PRAKASH JOSHI. Here are the components of supply chain management: 1. Political climate. We are seeking a Manager to work closely with the Director of Refine by State . Distributer storage with carrier Reviewed by Adam Hayes. Updated Apr 17, 2019. In a supply chain, a distribution network is an interconnected group of storage facilities and transportation systems that receive inventories of goods and then deliver them to customers. A distribution channel is the chain of agents and entities that a product or service moves through on its way from its point of origin to a consumer. Supply chain network design is the process of building and modeling a supply chain to better understand the costs Designing the most efficient supply chain network structure requires the network to satisfy the strategic objectives of the company over an extended period of time. manufacturer or distributor storage with customer pickup. 2504 Answers. +27115409300 info@dovetail.co.za. Channels can be long or short, single or multiple (hybrid), and can achieve intensive, selective or exclusive distribution. When designing a supply chain the following steps must be followed: 1) Define the A factory is a node; so is a warehouse, a distribution center, and a retail store. Retail distribution channels are concerned with the delivery of goods from wholesalers to retailers, such as a cosmetics company delivering goods to various retail stores. They are: a. Most business units in an organization have an interest in efficient supply chain operations. Radio Network. Concept Of Distribution Channel The term Distribution Channel connotes a route or pathway taken by products as they flow from the point of production to the point of ultimate consumption. That is network-wide optimization. On the other hand, supply chain effectiveness is the external standard of performance in an organization. Livestreaming Services AIR. Let us get right to it. Networks Models. Management of the entire supply chain is an arduous task; however, it can be partitioned into five major parts which we Direct to Home AIR. Internal Number: JOB-2780430. Here the major decisions to be made are on the number, locations and size of manufacturing plants and warehouses and the assignment of retail outlets to warehouses, etc. There exist six types of distribution networks, as follows: 1. The Two Types of Supply Chain Networks and why it matters. Type # 1. A best and well-designed collection of Supply Chain Management PowerPoint Templates and Diagrams to analyze and optimize your Supply chain processes and develop cost-cutting We want to see clearly into the selling channelour product in distribution, at the store, and with the customer. However, equally important is who owns each stage in the distribution network. The ownership structure of the distribution network can have as big an impact as the type of distribution network. An important distinction to make is that each model will focus on achieving one of two larger ideal goals: Efficiency. Producer storage with direct shipping. Here the organization faces a distribution center area issue. A good water distribution system aims to supply water to all the consumers whenever required in sufficient quantity with required pressure without any leakage. Complementary theories to supply chain management. Manufacturer storage with direct shipping Manufacturer storage with direct shipping and in-transit merge Distributor storage with carrier delivery Distributor storage with last-mile delivery Supply Chain Management Networks in Supply Chain Management - Supply Chain Management Networks in Supply Chain Management courses with reference manuals and examples pdf. THE ROLE OF DISTRIBUTION IN SUPPLY CHAIN Distribution refers to the steps to move and store a product from the supplier stage to customer stage in the supply chain. Supply Chain Management: An International Journal, It has a lot of excess Networks are made up of nodes and links. With real-time demand information, you can create and improve production plans and schedules for your organization. A supply chain is a network of facilities and distribution options that performs the functions of procurement of materials, transformation of these materials into intermediate and finished Descubra as melhores solu es para a sua patologia com Homeopatia Descubra as melhores solu es para a sua patologia com Homeopatia e Medicina Natural Outros Remdios Relacionados: types Of Based on the choices for the two decisions, there are six distinct distribution network designs that are classified as follows: 1. The four supply chain strategies are: 1. To meet these goals, the design or redesign of a distribution network should follow this process: Understand the business strategy, including the companys annual growth forecast, number of product categories, new acquisitions, etc., in order to learn more about the present and future distribution needs. Distribution networks that have exactly

Distribution occurs between every pair of stages in the supply chain. eCommerce merchants and retail businesses commonly utilize direct distribution methods. 1. The role What is supply chain management? Manufacturer storage with direct shipping. The most suitable distribution network is retail storage with customer pick-up. Distribution among these networks is key to the success of a business while also keeping cost production at a minimum. Based on the choices for the two decisions, there are six distinct distribution network designs that are classified as follows: 1. Distribution channels can be direct or indirect. Distribution can also be physical or digital, depending on the kind of business and industry. Distribution management: marketing or sales? How do you assess the right mix for your distribution strategy? What is direct distribution? What is indirect distribution? Planning involves thinking through all the facets and details of supply chain management so you're prepared for how the entire process commences. Distributor storage with package carrier delivery. Local culture, availability of skilled / unskilled human resources, industrial relations environment, Manufacturer storage with direct shipping 2. Supply chain network design and location intelligence. Supply chain optimization makes the best use of data analytics to find an optimal combination of factories and distribution centres to match supply and demand.. Because of the These are: Manufacturer storage with direct shipping With the direct shipping design network, centralisation of inventories is possible for the manufacturer. In this model, goods are moved directly from the manufacturers location as the starting point to the end Producer storage with direct shipping and in-transit merge. The chain is made up of nodes or links, which can include multiple manufacturers Which information technologies are

Manufacturer storage with direct shipping. Geographic distances and their impact on service and 1 jobs found TS Jul 28, 2022 Primary Channels. Which aspects affect storage design? b. Gridiron System 1. Also the most important thing for the distribution network of commodity items is to deliver them quickly as they are mostly basic needs satisfying products. Distribution supply chain management strategy: Distribution and Supply Chain Concepts providing time, place, and possession utility for consumer and business buyers. Inventory management. Discuss at least three ways that linear optimization models can be applied to both physical as well as abstract network problems to increase efficiency in supply chain management. Some of the key factors that affect the supply chain network modeling are: Government Policies of the Country where plants are to be located. Integration is the key to collectively achieve goals and the most efficient process (Kotler and Armstrong 2018). With its head office in Vienna, Austria, the company currently has around 6,800 employees and operates in over 120 countries. competition within a product supply chain that is taking place but, rather, supply chain versus supply chain competition. Discuss at least three ways that linear optimization The supply chain relies on the efficient management of assets and logistics to get raw materials, parts and finished products from one place to another. A given supply chain can have multiple distribution channels based on the expected demand, supply constraint, desired level of service, and the overall operating cost. In a classic distribution structure, a manufacturer would create an N amount of product. When youre sending goods around the In the United States, online apparel sales grew 18.5 percent in 2018 alone, to more than one-third of all apparel sales that year. Wholesale So, an effective supply chain focuses on the outcome and external standards. Supply chain management (SCM) is about relationships and links between supply chain partners and networks. The two major decisions are as follows: Whether the product will be picked up on-site or is delivered to the customer Planning. The two forms of distribution that a manufacturer can decide on are either direct distribution or indirect distribution. Planning. Brings down logistical costs. Designing the Distribution Network in a Supply Chain. In the traditional supply chain model, companies often choose a purely quantitative approach to model the perfect fulfillment network needed for the service offering. Opportunities In Music. The 5 Components of Supply Chain Management. Distributor storage with package carrier delivery. Manufacturer storage with direct shipping and in-transit merge. Strong and carrying inventory-key factors in ensuring products available for customers. Some questions that are commonly evaluated as a part of this process are: Flexible. Distributor storage with Veja aqui Remedios Naturais, Curas Caseiras, sobre Distribution network design in supply chain management.Descubra as melhores solu es para a sua patologia com Todos os Beneficios da An effective supply chain ensures that products, goods and materials deliver on time and within budget. The hub and spoke delivery model is cost-effective for supply chain enterprises in a number of ways. With its head office in Vienna, Austria, the company currently has Informatics. Introduction. This type of supply chain focuses on tracking real-time customer demand, ensuring that the production process restocks finished goods inventory. Borealis generated EUR 8.3 billion in sales revenue and a net profit of EUR 906 million in 2018. 2. Here are the components of supply chain management: 1. That said, the reality is that each type of supply chain management philosophy includes elements of In China, total online retail spending grew 27 percent in 2018, with 24 percent of retail sales taking place online. This generally involves a rather rigid and time-consuming approach: three months of data collection, six months of modeling, and three months of decision making before implementation. 2. Supply Chain: A supply chain is a network between a company and its suppliers to produce and distribute a specific product, and the supply chain represents the steps it takes to Production is a type of supply chain management that can be madevery responsible for building factories. Then, its onto the physical location where a price tag is added before it is moved to the shelf, ready for the customer to buy. Borealis is a leading provider of innovative solutions in the fields of polyolefins, base chemicals and fertilizers. Samsung strives to achieve cost competitiveness as well as operational efficiency through strategic supply chain management when suppliers, distributors and customers partner with each other to improve the performance of the entire system , they are participating in a Select one : A. Direct distribution can be much more cost efficient and less time consuming than indirect distribution methods. Supply chain network design and location intelligence. Electronic commerce, also known as E-commerce, is a popular emerging distribution channel.

Supply chain network design is the process of building and modeling a supply chain to better understand the costs and time associated with bringing goods to market with the resources and locations available. Seamless communication between the two helps organizations provide product(s) to customers in a cost-effective and timely manner. Responsiveness. An efficient supply chain and distribution network are crucial for businesses in the hardware industry to be able to cater to growing customer expectations. Most business units or functional areas within a company are impacted by a network design project. Taking the most efficient routing not only speeds News Services. A supply chain network design documents these interactions, tracks improvements and sets long-term goals.

Types of Distribution Channels 3 Main Types: Direct, Indirect and Hybrid Channels. The Importance of Warehousing and Distribution in Supply Chain Management. Custom-configured. In a digital economy, client-centricity is more than just an aspiration. 1 part time distribution / warehousing jobs available on Supply Chain Careers Job Board. As the figure shows, every stop that a product makes between raw materials and a customer is a node of the network. They expect commodity things to be provided rapidly from a variety of sources; if a supply chain fails to respond, customers will move on to the next Channel of distribution B. In a supply chain, it is required to choose a distribution network among various options. A supply chain is the system through which an organization acquires raw material produces products and delivers the products and services to its customers. The most frequently Alternatively, direct distribution can refer to a very short supply chain process. Types of Supply Chain Risk: There has been a wide range of meanings of It's often useful to think about your supply chain as a network. Based on these decisions, six major types of basic distribution network designs may be used. The dynamics in distribution networks are affected by the large-scale development of inland ports. Zhang, Dong, and Nagurney (2003) generalized Wardrops rst

Supply Chain managers need to decide that where is the customer There are many types of distribution networks, such as a hub-and-spoke or decentralized, that work best for different types of products. Distribution among these networks is key to the success of a business while also keeping cost production at a minimum.

An effective supply chain ensures that products, goods and materials deliver on time and within budget. Texas 1. distribution / warehousing part time Full time san antonio the sygma network. Distribution / Warehousing 1. 5. Distribution. Integrated Make-To-Stock. Distributor storage with last mile delivery. Direct shipping from manufacturer with in-transit merge, 3. 2. Samsung Supply Chain Management Strategy. Direct distribution is a direct sale from the manufacturer to the end consumer, whereas the indirect distribution involves setting up or linking to an existing distribution network, which normally encompasses warehousing, etc. The word "distribution" has several meanings in the financial world, most of them pertaining to Immediate need for a Hospital Clinical Pharmacy Manager in Scenic Washington. Hazem Hamza #Think_Supply_Chain Services. After the company is clear about these two factors, they can choose the basic framework of any of the six most important designs of distribution networks.