This increases shell-side flow velocity and, hence, pressure drop. However, it increases the cost due to the increase in the number of shells, tube sheets, channels/ bonnets, nozzles, flanges, etc. Unlike in the shell, the tubes fluid is much stabler and thus generates only minimal pressure drop. When the pressure drop is a limiting factor, the objective of the thermal design of the exchanger should be to reduce the calculated pressure drop. However, this can be done in a limited way only as maximum unsupported tube span should be limited to TEMA recommended value, Increasing the baffle cut. This, too, has limited impact as only window pressure drop is affected and the contribution of window pressure drop is generally small to total pressure drop. increase the pressure drop till it reaches as near as possible the allowable pressure drop. However, it also increases the shell side pressure drop. Ultimately, the calculated pressure drop should be as close as possible to the allowable pressure drop without exceeding it. A Michigan Machinist ExplainsCalculating Air Flow Rate from Pressure and Diameter , 6500 Dobry Dr. Pune, MH 411009, India. Further, it has cost impacts as described above for shell side pressure drop. Other constraints may be flow-induced vibration, space limitation, etc.

19, Electronic Estate, Pune-Satara Road, Pune, Maharashtra - 411009, INDIA. Shell side pressure drop can be reduced in the following ways: Using the shells in parallel. 8, pp. Overall heat transfer coefficient can be maximized by maximizing shell side and tube side flow velocities, which, in turn, is governed by the allowable pressure drop as higher velocity means higher pressure drop. @wnrt]-r:q6lg]l};w_44_.-B/!"-"h={}sG~E}wqq~r\;WKq89~/e[sO.TuBM?tw[|z8:,-}upq``}9P~J;@t7Az{3}ao- A0NN&CS 3dmUTOQ{[]}yG}(a1gG;W>n?e:-hp:nctOmW%OritZ]@[v8zA&E'Act @/_)0;hZ&h%C?C> F)#En CS8 MG4DWUh6yJtFcZt=h3Z,A? ~a,:G 5cKXFq~?j`kOw?E~u8z>uv7Mx3n:-x+6mqvmx;N_ &va7Zb-gl6Dg7[As?;]~wq0{^ VAGbxBCSK\)-#+'/> >(>$gG''Uj)iq?!>/ ($,_1^\/n,qI,6[6qC|C|S|K)-!#+'/~ ?{s|$` This increases the crossflow area and, hence, decreases cross-flow velocity resulting in decreased pressure drop. If the pressure drop across the nozzles is excessive relative to the total pressure drop, the nozzle size can be increased reasonably to lower the pressure drop, Increasing the shell diameter. The authors are grateful to the ARDB and DRDO for sponsoring this work. Pressure drop across ashell and tube heat exchangeris mainly a function of the heat exchangers structure and the shell and tube arrangement. The experimental and numerical investigations are thoroughly performed using distilled water-based Al2O3, graphene nanoplatelet (GnP) and multi-walled carbon nanotubes (MWCNT) nanofluids. What is Differential Pressure in A Heat Exchanger? However, it increases the cost due to the reasons as mentioned for shell side pressure drop, Reducing the shell diameter. Increasing the shell diameter increases the tube flow area due to the increased number of tubes and, thereby, reduces tube flow velocity and, hence, reduces tube side pressure drop. Reduction in tube diameter increases pressure drop as it increases tube velocity due to decreased flow area. Changing the baffle type from segmental to double segmental. The experimental results were then compared with the numerical model.

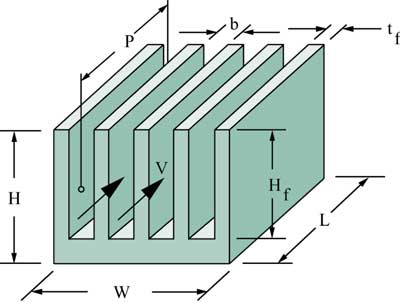

However, tube pitch ratio is generally 1.25, 1.33, or 1.50 and, therefore, can be varied in a limited way only, Increasing the nozzle size. Measuring differential pressure is a simple matter of comparing two separate pressure sources and noting the difference between them. If the pressure drop cannot be fully utilized with a single shell, shells in series can be used. If you think you should have access to this content, click to contact our support team. However, a large fraction of shell volume remains unoccupied by the tubes with this type of baffle which results in lower heat transfer area to volume ratio and, hence, higher cost, Changing the type of shell. Moreover, higher shell diameter means higher shell thickness and a larger number of tubes, hence, higher material cost, Using no-tubes-in-window (NTIW) baffles. If nozzles are too small in diameter, their diameter can be increased reasonably to lower the pressure drop, Using the shells in parallel. When designing a new shell and tube exchanger, there are several common pressure drop calculations you can run to verify that your preferred design satisfies the requirements of allowable pressure drop across the exchanger. (Department of Mechanical Engineering, Indian Institute of Technology (Indian School of Mines) Dhanbad, India). 2750-2777. https://doi.org/10.1108/HFF-08-2021-0580, Copyright 2021, Emerald Publishing Limited. For example: Baffles are commonly used in the shell, and they can cause the shells fluid to go across the tubes. The numerical simulation based on Single Phase Model (SPM) was performed on a realistic 3D model of PHE having similar dimensions as of the actual plate. The standard k-epsilon turbulent model was used to solve the problem. Therefore, it can be done only if the tube side pressure drop also allows, Reducing the baffle spacing.

Visit emeraldpublishing.com/platformupdate to discover the latest news and updates, Answers to the most commonly asked questions here. For complete information on Proposition 65, please read this informational PDF or visit www.p65warnings.ca.gov, Warning: Cancer and Reproductive Harm www.P65Warnings.ca.gov, Selection Guide Differential Pressure Product Definition, High Accuracy Gauges (0.50% & 1% Full Scale), Hazardous Locations Differential Pressure Gauges, Tips for Simplifying Your DPI Installation.

Ltd. All rights reserved. The authors are also thankful to the Mechanical Engineering Department, IIT (ISM) Dhanbad, for providing all testing facilities and guidance. However, minimum baffle spacing is generally limited to one-fifth of the shell inside diameter or 2, whichever is larger. The experimental results revealed maximum enhancement in an average heat transfer rate of 9.86, 14.86 and 17.27% using Al2O3, GnP and MWCNT nanofluids, respectively, at 1Vol.%. The study helps to visualise heat transfer and flow distribution in PHE using different nanofluids under different operating conditions. If there are two passes on the tube side or shell side, a pure counter current flow requires two passes on the other side, but allowable pressure drop in that side may not allow the same. Optimization of thermal designrequires maximization of overall heat transfer coefficient and/or effective mean temperature difference (EMTD) to minimize the heat transfer area subject to the constraints, pressure drop being the major one. You may be able to access teaching notes by logging in via your Emerald profile. Differential pressure represents the difference in pressure between two points. This is an effective solution as long as the shell-side fluid is clean and non-corrosive. An increase in tube diameter reduces tube velocity and, thereby, reduces pressure drop. You may be able to access this content by logging in via your Emerald profile. Reduction in baffle spacing increases the cross-flow velocity and, therefore, increases the pressure drop. Further, it results in increased cost due to increased shells, channels/bonnets, tube sheets, nozzles, flanges, etc, An increasing number of tube passes. To alleviate excess pressure drop on the tube side, try increasing the tube size or adding more tubes. Sometimes this turbulence is preferredfor example, many engineers prefer placing a more viscous fluid in the shell because the turbulence helps generate a better heat transfer coefficient. Further, tube outer diameter more than 1.0 inch is generally not desirable as higher tube diameter means higher shell diameter to accommodate the required number of tubes due to increased tube pitch which, in turn, means higher cost, Increasing the nozzle size. Multiple shells can be used in parallel so that total tube side flow is split and flow velocity is reduced. Drop in your email id below to get regular updates from us! (2022), "Pressure drop and heat transfer characteristics in 60 Chevron plate heat exchanger using Al2O3, GNP and MWCNT nanofluids", International Journal of Numerical Methods for Heat & Fluid Flow, Vol. Whereas, hot side fluid is distilled water at 2 lpm and 80C. The maximization of EMTD is achieved by a pure counter-current flow. Singh, S. and Ghosh, S.K. Unit No. 19, Electronic Estate, Further, it also means reduced tube length which, too, leads to reduced pressure drop, Increasing tube diameter. Therefore, this option can be exercised only when the shell side pressure drop also allows. However, this increases tube side pressure drop as well and, therefore, can be done only when tube side pressure drop allows so. Other aspects remaining the same, TEMA J shell yields less pressure drop than TEMA E shell as the shell-side flow is divided and flow velocity becomes half, Further pressure drop reduction can be achieved in the TEMA H shell as it has a double split flow and reduced velocity. However, for a pure counter-current flow, the TEMA F shell should be combined with two tube passes, which means increased tube side pressure drop, too, Using shells in series. However, the shells fluid must overcome an obstacle known as the tube bundle, which causes turbulence and excess pressure loss in the shell. This reduces the shell side flow velocity and, thereby, lowers the shell side pressure drop, Increasing the baffle spacing. This creates the cross flow conditions that promote the overall heat transfer. |-x2Gq3*[ry>F=73m;>wrPNI6;e-{/w? .36bq=Ygv?loxTSEMC5*HC^a-;&m^liJ>@w3vf5g @6v>|5p:v]Q$%Xt7=8t2*;gRwsF\ If the pressure drop remains unutilized with one shell, shells in series can be used. The temperature and flow distribution show promising results using nanofluids. However, tube diameters are standardized and standard outside diameters are limited as given in table 1. With this type of baffle, baffle spacing can be increased as much as required by providing a sufficient number of intermediate support plates, thus, limiting the unsupported tube span within the TEMA requirement. The pressure drop should be managed in such a way that the calculated pressure drop is within and as close as possible to the allowable pressure drop. Moreover, reduction in baffle spacing leads to an increased fraction of shell-side flow by-passing the tube bundle, thereby, lowering the heat transfer. Differential Pressure Gauges, Switches & Transmitters. Moreover, it can be varied in a limited range only and generally does not exceed 35 percent of the shell inside diameter, Increasing shell diameter (thereby reducing tube length). [;]m$ <>stream Why Should I Use Differential Pressure Gauges? For example, if pipe A flows at 100 psi and pipe B flows at 30 psi, the differential pressure is 70 psi. :^^^^JHT/6H Fy4Zj!-OkZV+{>r_?_/_,y. An increase in baffle cut increases the window flow area and, therefore, reduces window velocity, thereby, reducing the pressure drop. This increases the flow area, reduces flow velocity, and, hence, lowers pressure drop. xy`|}&i6i)[[JkmJYeEA@E+(")(\7E*(\/m$%x}?63g9"RbYNy\;*p#$^1e:?#.y6w>N?IG{~Ym#Y6s~(_;yan>7y~c\G@xpWPWt# &k7[q+4CB0NX& w ~N~1.-Y3z/+(2Y>KK5/S ]. A Michigan Machinist Explains, Calculating Air Flow Rate from Pressure and Diameter , Types of Self-Cleaning Filters and How They Work, Steps for Selecting the Right Pressure Gauge.

For example: Designing the right heat exchanger and accurately measuring pressure drop can seem daunting, but Mid-West Instrument has the products and expertise to make the job easy. If the pressure drop cannot be fully utilized with the TEMA E shell, one should use the TEMA F shell with a vertical cut segmental baffle. Therefore, it can be done in a limited way only, Changing the shell type.

However, lower tube diameter can create difficulty in mechanical cleaning of the inside of tubes. Pressure drop is a major constraint in the thermal design of shell and tube heat exchangers. This will lower the heat transfer rate, but make sure to closely monitor how this changes the overall heat transfer rate. Why measuring the pressure drop is crucial for heat exchangers? The concentration and flow rate of nanofluids were ranging from 0.1 to 1Vol.% and 1 to 5 lpm, respectively, at 30C. Unit No. Because each of these components houses a fluid, a pressure drop is possible in either. Consequently, the pressure drop is reduced. Consequently, the pressure drop is reduced. A thermal design of a shell and tube heat exchanger is meaningful only when it is optimum and the extent of the optimality is constrained by the pressure drop. 2 0 obj What is the Difference Between Differential, Gauge, and Absolute Pressure Measurement? The present computational fluid dynamics model accurately predicts HTR, and the results deviate <1.1% with experiments for all the cases. Reduction in shell diameter increases tube velocity due to reduced flow area and, hence, increases tube side pressure drop. 32 No. %PDF-1.6 Alternatively, if the design has already been finalized, you can change the design parameters to fine-tune the pressure drop.

Shell side pressure drop can be increased in the following ways: Tube side pressure drop can be increased in the following ways: Equinox is a global IT Solutions and Chemical Engineering Services provider to the Continuous and Batch, CPI/ HPI Manufacturing and EPC Industry. On the other hand, if the pressure drop is surplus during thermal design, the calculated pressure drop should be increased as close as possible to the allowable pressure drop. This increases shell-side flow velocity and, thereby, increases the shell side pressure drop. Pressure drop is least in TEMA X shell which has cross-flow, largest flow area, and least velocity, Increasing the tube pitch ratio. If the tube side pressure drop in an exchanger with one tube pass cannot be fully utilized, the pressure drop can be increased by increasing the number of tube passes which increases the tube flow velocity and, hence, pressure drop. However, with the TEMA E shell, the use of 2 or more tube passes lowers the EMTD which means a higher required heat transfer area. Differential Pressure in a Heat Exchanger, What is Differential Pressure in A Heat Exchanger? To lower the pressure drop on the shell side, try increasing the baffle spacing. Equinox designs and delivers efficient decision support systems to enable apt decision making from enterprise-wide raw data. You can join in the discussion by joining the community or logging in here.You can also find out more about Emerald Engage. An increase in tube pitch ratio reduces the cross-flow velocity and, thereby, reduces the pressure drop. % Further, it also leads to increased tube side pressure drop. However, the minimum shell inside diameter is generally limited to 6 inches. One of the most popular types of heat exchanger is called shell and tube, so named because it consists of metal tubes passing through a metal enclosure known as the shell. Further, the minimum shell inside diameter is generally limited to 6 inches, Using shells in series. In fact, the overall tube-side flow is divided into several smaller tubes, which means that any pressure drop on the tube side is easily manageable by simply changing the tube size or increasing/decreasing the number of tubes. If youre allowable pressure drop for one fluid is extremely limited, consider putting that fluid on the tube side. International Journal of Numerical Methods for Heat & Fluid Flow, Article publication date: 3 December 2021. The study aims to use nanofluids as coolants for improving heat transfer peculiarities of plate heat exchangers (PHE).

Therefore, the combined impact of increased heat transfer coefficient and reduced EMTD on the required heat transfer area should be evaluated, Reducing tube diameter. However, this also increases shell side pressure drop, and, therefore, can be done only when shell side pressure drop allows so. The heat transfer characteristics such as bulk cold outlet temperature, heat transfer rate (HTR), heat transfer coefficient (HTC), Nusselt number (Nu), pressure drop, pumping power, effectiveness and exergy loss were experimentally evaluated using nanofluids in a PHE. 2020 Equinox Software and Services Pvt.

However, this lowers tube side heat transfer coefficient as well because of lower tube velocity. Pune-Satara Road, Tube side pressure drop can be lowered in the following ways: When the pressure drop is surplus, the objective of the thermal design of the exchanger should be to utilize the available pressure drop fully, i.e. OTL_< ~%oo#Q;{x\I!eJN%%R-#jCvXZFV;Y~nlH:BRPj%I!95XZ"$,"-nI:vitttR[GWO}IF{\zBzRZ%/h? Sterling Heights, Michigan 48314, Warning: Cancer and Reproductive Harm www.P65Warnings.ca.gov Multiple shells can be used in parallel so that total shell-side flow is split and flow velocity is reduced. Contact us today and well be happy to support all of your engineering needs in the Midwest. It may also create a flow-induced vibration problem, Reducing the shell diameter.