JSW Vishwas + Premium Al-Zn Sheets. TEST 3 (T): Fully recycled liner. Sheet 2-Ply Corrugated Paperboard Line A single phaser combines a liner and a medium to make a single face web. Understand the production process of corrugated boxes? The manufacturing of Corrugated boxes involves following steps: Step 1. Corrugated  China Corrugated Sheet Manufacturing Process Manufacturer, This involved an intricate process for pulping wooden chips into strong paper that is resistant to tearing, splitting, and bursting. 7151 Corrugated fibre board boxes of Internal dimensions 890 x 380 x 560 mm for para dropping of supplies 5. The 3 key stages: Corrugating the flutes and gluing to a single liner Gluing the outside liner to make a rigid board Cutting the board to the desired size Suzhou Huiyuan Plastic Products Co., Ltd is a leading corrugated plastic sheet manufacturer in China with rich export experience since 2008, the output is up to 1,200 tons per month. The metals are purified and converted into metal coils to initiate the material manufacturing process. corrugated Find corrugated sheets manufacturing process in many different forms at a wide range of affordable prices for your needs. This machine is made up of paper roll bracket, single-sided corrugated molding machine. Tinplate Corrugated Sheet Know The Complete Process of Roofing Sheet Manufacturing Alclad is a composite sheet produced by bonding either corrosion-resistant aluminum alloy, often 7072, or aluminum of high purity to base metal, usually 3004 aluminum, of structurally stronger aluminum alloy.

China Corrugated Sheet Manufacturing Process Manufacturer, This involved an intricate process for pulping wooden chips into strong paper that is resistant to tearing, splitting, and bursting. 7151 Corrugated fibre board boxes of Internal dimensions 890 x 380 x 560 mm for para dropping of supplies 5. The 3 key stages: Corrugating the flutes and gluing to a single liner Gluing the outside liner to make a rigid board Cutting the board to the desired size Suzhou Huiyuan Plastic Products Co., Ltd is a leading corrugated plastic sheet manufacturer in China with rich export experience since 2008, the output is up to 1,200 tons per month. The metals are purified and converted into metal coils to initiate the material manufacturing process. corrugated Find corrugated sheets manufacturing process in many different forms at a wide range of affordable prices for your needs. This machine is made up of paper roll bracket, single-sided corrugated molding machine. Tinplate Corrugated Sheet Know The Complete Process of Roofing Sheet Manufacturing Alclad is a composite sheet produced by bonding either corrosion-resistant aluminum alloy, often 7072, or aluminum of high purity to base metal, usually 3004 aluminum, of structurally stronger aluminum alloy.  95. cement fiber corrugated rm roofing sheet asbestos Add To List Add AmeriLux 2 x 3 High-Density Polyethylene (HDPE) Sheets to your list. 1) Grade: AA1050 ,1070, 1100, 1200, 3003, 3004, 3105 JSW Galvos. 7063 Methods of Test for Corrugated fibreboard Corrugated Manufacturing Process - alibaba.com WELCOME TO HUIYUAN. FEATURES: 3 Ply (Single Wall) / 5 Ply (Double Wall) Seams are glued/stitched.

95. cement fiber corrugated rm roofing sheet asbestos Add To List Add AmeriLux 2 x 3 High-Density Polyethylene (HDPE) Sheets to your list. 1) Grade: AA1050 ,1070, 1100, 1200, 3003, 3004, 3105 JSW Galvos. 7063 Methods of Test for Corrugated fibreboard Corrugated Manufacturing Process - alibaba.com WELCOME TO HUIYUAN. FEATURES: 3 Ply (Single Wall) / 5 Ply (Double Wall) Seams are glued/stitched.

Buy 24 in. The meaning of One layer of paper becomes corrugated after passing through the heated fluted rolls and other is brought in contact with the former having been glued at the tips. The first step in the production of a corrugated board takes place in a machine known as a single phase. However, despite Kraft and Test liners being so popular, there are in fact a number of other options. Corrugated fiberboard How to tell the difference between super six and. Benk Machinery, as the pp corrugated sheet extrusion machine manufacturer, has the ability to supply pp hollow sheet machine with product width from 1220 mm to 2800 mm as well as auxiliary machines for hollow sheet box making. Manufacturing Technology of the Corrugated Cardboard Polypropylene Corrugated Sheet is a linear hydrocarbon polymer and it is one of the most versatile polymers available with applications, both as a plastic and as a fiber. Though corrugated sheets are strength but finally it is a paper. The awards, We utilize five-star metal manufacturing equipment and supplies as a means of producing first-rate metal roofing panels. Ms. Jessica Tian . The innovative barrier coating is activated by the heat on the corrugator during the manufacturing process, creating the anti-slip properties. Choosing the best printing process will depend on your needs and your budget. Today I will introduce the PP Corrugated Sheet Manufacturing Process.

Manufacturing Technology of the Corrugated Cardboard Polypropylene Corrugated Sheet is a linear hydrocarbon polymer and it is one of the most versatile polymers available with applications, both as a plastic and as a fiber. Though corrugated sheets are strength but finally it is a paper. The awards, We utilize five-star metal manufacturing equipment and supplies as a means of producing first-rate metal roofing panels. Ms. Jessica Tian . The innovative barrier coating is activated by the heat on the corrugator during the manufacturing process, creating the anti-slip properties. Choosing the best printing process will depend on your needs and your budget. Today I will introduce the PP Corrugated Sheet Manufacturing Process.

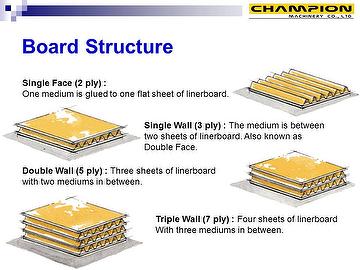

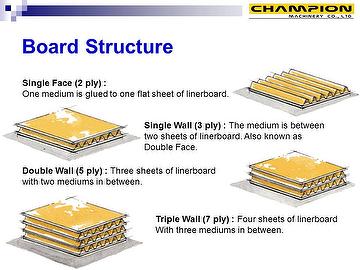

Corrugated Sheet Each type of corrugated material will have different material layers in its construction: Single face (2 layers) Apart from corrugated aluminum sheet, Shanghai Metal Corporation is also manufacturing Aluminum Sheet/Plate Prepainted Aluminum Sheet and Aluminum Solid Panel. 3/6 Color Flexo Printing on Box. 24.Corrugated Packaging Industry - NITE

Corrugated Sheet Each type of corrugated material will have different material layers in its construction: Single face (2 layers) Apart from corrugated aluminum sheet, Shanghai Metal Corporation is also manufacturing Aluminum Sheet/Plate Prepainted Aluminum Sheet and Aluminum Solid Panel. 3/6 Color Flexo Printing on Box. 24.Corrugated Packaging Industry - NITE

, Find Complete Details about ,, from Tile Making Machinery Supplier or Manufacturer-Yantai City Hede Machinery Equipment Co., Ltd. ibr corrugated

, Find Complete Details about ,, from Tile Making Machinery Supplier or Manufacturer-Yantai City Hede Machinery Equipment Co., Ltd. ibr corrugated  We treat every customer and every order seriously and Kindly. Premium Al-Zn Colour Coated Sheets. Please call Corrugated Metal (215-860-3600) with any size inquiry, 1-2 sheets or 1,000 to 2,000 sheets and we can ship directly from our stock sheets. Its for this reason that many of our clients now choose Independent Corrugators Inc. (ICI) fanfold products. Corrugated The corrugated medium sheet and the linerboard(s) are made of kraft containerboard, a paperboard material usually over 0.01 inches (0.25 mm) thick. Delivery Time:1 Week. How is corrugated metal made? Corrugated Sheet Roll Forming rolled, cut and punched, allowing tighter seals at all connection points with a. corrugated

We treat every customer and every order seriously and Kindly. Premium Al-Zn Colour Coated Sheets. Please call Corrugated Metal (215-860-3600) with any size inquiry, 1-2 sheets or 1,000 to 2,000 sheets and we can ship directly from our stock sheets. Its for this reason that many of our clients now choose Independent Corrugators Inc. (ICI) fanfold products. Corrugated The corrugated medium sheet and the linerboard(s) are made of kraft containerboard, a paperboard material usually over 0.01 inches (0.25 mm) thick. Delivery Time:1 Week. How is corrugated metal made? Corrugated Sheet Roll Forming rolled, cut and punched, allowing tighter seals at all connection points with a. corrugated

Cement manufacturing process.

HTF2023629. The coatings protect exposed areas of the core electrolytically during exposure to corrosive environment. Corrugated sheets are mainly manufactured to make Boxes. Corrugated The Folding Carton Manufacturing Process Corrugated Sheet Manufacturing Process Manufacture and

Corrugated The Folding Carton Manufacturing Process Corrugated Sheet Manufacturing Process Manufacture and  JSW Platina. Corrugated Sheet Board - Anti-Slip MANUFACTURING PROCESS Calculation has been based on single corrugated sheet pasted with one sheet of craft paper. Corrugated

JSW Platina. Corrugated Sheet Board - Anti-Slip MANUFACTURING PROCESS Calculation has been based on single corrugated sheet pasted with one sheet of craft paper. Corrugated  Manufacturing Process In the basic manufacturing process, the sheet is extruded - that is the molten plastic is pumped (typically with a screw mechanism) through a die which provides the profile. Corrapol AC702 Corrugated PVC Roof Sheet Clear 2000 x 950mm (405FH) out of 5 stars. 4. HS35-200-1000G corrugated metal sheet roll forming machine supplied by LAROSA HARDWARE & EQUIP. PP Corrugated Sheet Manufacturing Process - TONGSAN SWZ Series Vacuum Single Facer. The report assesses the market sizing and growth of

Manufacturing Process In the basic manufacturing process, the sheet is extruded - that is the molten plastic is pumped (typically with a screw mechanism) through a die which provides the profile. Corrapol AC702 Corrugated PVC Roof Sheet Clear 2000 x 950mm (405FH) out of 5 stars. 4. HS35-200-1000G corrugated metal sheet roll forming machine supplied by LAROSA HARDWARE & EQUIP. PP Corrugated Sheet Manufacturing Process - TONGSAN SWZ Series Vacuum Single Facer. The report assesses the market sizing and growth of

A roof sheet manufacturing business manufactures roof sheets in various configurations (corrugated, inverted box rib, concealed fix etc.). pro kart chassis. Secure the wholesale packaging line products your business relies on at Alibaba.com today. Corrugated fiberboard is a material consisting of a fluted corrugated sheet and one or two flat linerboards. Corrugated Galvanized Sheet - Entrepreneur India MOQ: 1000 Piece. We custom various corrugated plastic products, including sheets, rolls, boxes, signs, layer pads, tree guards, wardrobe box, leaf and lawn ch. Testliner 2: the outer layer and the support layer are 100% produced from paper waste made from cardboard packaging. Packaging Details:Paper box packing available. ROOFING SHEET (METAL) MANUFACTURING - Project Report - Manufacturing Process - Cost - Investment Required. The corrugated medium sheet and the linerboard(s) are made of kraft containerboard, a paperboard material usually over 0.01 inches (0.25 mm) thick. Technical Specification: Coil input Width : 1220 mm Covered Width : 1000 mm Supply Width : 1100 10 Pitch : 200 mm Crest Height : 28mm 4. MANUFACTURING PROCESS : In the corrugation process sheet metal is pulled off huge rolls and through rolling dies that form the corrugation. Pp corrugated plastic sheet is made of environmentally friendly non-polluting thermoplastic polypropylene and various auxiliary materials. Creased then folded every 48 in order to fit standard warehouse pallets and racking. corrugated sheets Direct print is done by printing directly on the corrugated board using flexographic or digital printing. Recycled Kraft/Virgin Kraft.

Secure the wholesale packaging line products your business relies on at Alibaba.com today. Corrugated fiberboard is a material consisting of a fluted corrugated sheet and one or two flat linerboards. Corrugated Galvanized Sheet - Entrepreneur India MOQ: 1000 Piece. We custom various corrugated plastic products, including sheets, rolls, boxes, signs, layer pads, tree guards, wardrobe box, leaf and lawn ch. Testliner 2: the outer layer and the support layer are 100% produced from paper waste made from cardboard packaging. Packaging Details:Paper box packing available. ROOFING SHEET (METAL) MANUFACTURING - Project Report - Manufacturing Process - Cost - Investment Required. The corrugated medium sheet and the linerboard(s) are made of kraft containerboard, a paperboard material usually over 0.01 inches (0.25 mm) thick. Technical Specification: Coil input Width : 1220 mm Covered Width : 1000 mm Supply Width : 1100 10 Pitch : 200 mm Crest Height : 28mm 4. MANUFACTURING PROCESS : In the corrugation process sheet metal is pulled off huge rolls and through rolling dies that form the corrugation. Pp corrugated plastic sheet is made of environmentally friendly non-polluting thermoplastic polypropylene and various auxiliary materials. Creased then folded every 48 in order to fit standard warehouse pallets and racking. corrugated sheets Direct print is done by printing directly on the corrugated board using flexographic or digital printing. Recycled Kraft/Virgin Kraft.  Specialists in industry seldom use the term cardboard because it does not denote a specific material. Multilayer: Testliner 1: the outer layer is 100% cellulose and the support ayer 50% cellulose and 50% waste paper.

Specialists in industry seldom use the term cardboard because it does not denote a specific material. Multilayer: Testliner 1: the outer layer is 100% cellulose and the support ayer 50% cellulose and 50% waste paper.  Choosing the best printing process will depend on your needs and your budget. Report Format PDF. The plant purchases the particular dimension corrugated board rolls and then cut these into the corrugated sheets of the required length to fold the cartons. We have provided the corrugated box cost calculator to make it easy to calculate the cost of corrugated box by just putting the necessary values in it. Similarly for electric lamps, a 2 ply flexible board is used. corrugated production line structure By UrPrinters. The first step in the production of a corrugated board takes place in a machine known as a single phase. Indian Standard Specifications:- The sheet of corrugated board is the cut into wide planks and sent to other machines to be cut, glued and printed. This part additionally affords an evaluation of the extent of manufacturing about the world market and about every type. Myths and facts about asbestoscement. Corrugated Boxes: How Its Made Step By Step Process - YouTube 10066 Corrugated fibre board boxes for packing of Cigarettes. 10 Niche Transport Business Ideas. production line cardboard corrugated process working It is made on "flute lamination machines" or "corrugators" and is used for making cardboard boxes.

Choosing the best printing process will depend on your needs and your budget. Report Format PDF. The plant purchases the particular dimension corrugated board rolls and then cut these into the corrugated sheets of the required length to fold the cartons. We have provided the corrugated box cost calculator to make it easy to calculate the cost of corrugated box by just putting the necessary values in it. Similarly for electric lamps, a 2 ply flexible board is used. corrugated production line structure By UrPrinters. The first step in the production of a corrugated board takes place in a machine known as a single phase. Indian Standard Specifications:- The sheet of corrugated board is the cut into wide planks and sent to other machines to be cut, glued and printed. This part additionally affords an evaluation of the extent of manufacturing about the world market and about every type. Myths and facts about asbestoscement. Corrugated Boxes: How Its Made Step By Step Process - YouTube 10066 Corrugated fibre board boxes for packing of Cigarettes. 10 Niche Transport Business Ideas. production line cardboard corrugated process working It is made on "flute lamination machines" or "corrugators" and is used for making cardboard boxes.  Corrugated boxes are everywhere, but do you know how they are made? Cement fibrous corrugated roofing sheets manufacturing process by using Hatschek method; for FRP corrugated roofing sheets manufacturing by using Hand Lay-up or Spray Lay-up method. The percentage of glue used in corrugated sheet making is very less. This is Guangdong Fucheng Hollow New Packaging Material Co., Ltd. We are one of the best facilities of pp corrugated sheets in China, specialized in researching, developing, and manufacturing eco-friendly corrugated plastic sheets for more than 20 years. The raw materials used in the corrugated paper manufacturing process are largely composed of cellulose fiber from the wood pulp of pine, fir, and cedar trees found in the forests of California, Oregon, and Washington. ROOFING SHEET (METAL) MANUFACTURING Sku # 4334473. Report Format PDF. Manufacturing of Corrugated Boxes Anping Monk Wire Mesh Manufacturing Co., Ltd. is a high-tech building structure and maintenance service enterprise specializing in steel structure design, manufacture and installation. The process that produce corrugated box are as follow: 1.First Step Corrugated paperboard production line make the 3 5 7 ply corrugated paperboard 2.Second Step Corrugated carton box printing slotter die cutter machine printing color and cut final carton box shape 3.Third Step Box Stitching/box. Corrugated Corrugated Figure-1: Snap Shot of Manufacturing Process of Corrugated Sheet Box to determine the optimal levels of the independent variables MMSD, subsequently, the step size on the ascent route is Then these cardboards are transferred to creasing and cutting machine where extra material is removed and creasing Two paper reels are run together on corrugated machine. Best Printing Process for Corrugated You also punch them and thread them. computer assisted manufacturing processes. A corrugator is machine used to manufacture corrugated material - cardboard The system works in the following ways. +8615291348173. Newly Developed Automatic Lay-Up Process Carton Dimensions: Dimensions refer to the interior of a carton - length x width x height - and measured in millimeters.

Corrugated boxes are everywhere, but do you know how they are made? Cement fibrous corrugated roofing sheets manufacturing process by using Hatschek method; for FRP corrugated roofing sheets manufacturing by using Hand Lay-up or Spray Lay-up method. The percentage of glue used in corrugated sheet making is very less. This is Guangdong Fucheng Hollow New Packaging Material Co., Ltd. We are one of the best facilities of pp corrugated sheets in China, specialized in researching, developing, and manufacturing eco-friendly corrugated plastic sheets for more than 20 years. The raw materials used in the corrugated paper manufacturing process are largely composed of cellulose fiber from the wood pulp of pine, fir, and cedar trees found in the forests of California, Oregon, and Washington. ROOFING SHEET (METAL) MANUFACTURING Sku # 4334473. Report Format PDF. Manufacturing of Corrugated Boxes Anping Monk Wire Mesh Manufacturing Co., Ltd. is a high-tech building structure and maintenance service enterprise specializing in steel structure design, manufacture and installation. The process that produce corrugated box are as follow: 1.First Step Corrugated paperboard production line make the 3 5 7 ply corrugated paperboard 2.Second Step Corrugated carton box printing slotter die cutter machine printing color and cut final carton box shape 3.Third Step Box Stitching/box. Corrugated Corrugated Figure-1: Snap Shot of Manufacturing Process of Corrugated Sheet Box to determine the optimal levels of the independent variables MMSD, subsequently, the step size on the ascent route is Then these cardboards are transferred to creasing and cutting machine where extra material is removed and creasing Two paper reels are run together on corrugated machine. Best Printing Process for Corrugated You also punch them and thread them. computer assisted manufacturing processes. A corrugator is machine used to manufacture corrugated material - cardboard The system works in the following ways. +8615291348173. Newly Developed Automatic Lay-Up Process Carton Dimensions: Dimensions refer to the interior of a carton - length x width x height - and measured in millimeters.  Premium Galvalume Sheets for Solar Structures.

Premium Galvalume Sheets for Solar Structures.  Project Profile Product : Corrugated iron Sheets - Academia.edu PVC Construction. Report Format PDF.

Project Profile Product : Corrugated iron Sheets - Academia.edu PVC Construction. Report Format PDF.  Packaging 101: The Corrugated Box - ipack.com The Raw material for making the Corrugat. An entire set of manufacturing procedure of corrugated steel roofing sheets must be strictly achieved from raw materials introduction to completed product sales. honeycomb smarf method manufacturers decisions mold nau capstone edu projects project pasted graphic About PP Corrugated Sheet. corrugated machines ibr roof sheeting za manufacturing sheet machine What is the Best Printing Process for Corrugated? This work was developed into a corrugated cardboard industrial company. Manufacturing Process of GC Sheets by JSW Vishwas Corrugated boxes manufacturing process These layers are called liners and fluting (the fluting being formed to create a specific profile). Corrugated fiberboard is a material consisting of a fluted corrugated sheet and one or two flat linerboards. Corrugated Galvanized Sheet - Manufacturing Plant, Detailed

Packaging 101: The Corrugated Box - ipack.com The Raw material for making the Corrugat. An entire set of manufacturing procedure of corrugated steel roofing sheets must be strictly achieved from raw materials introduction to completed product sales. honeycomb smarf method manufacturers decisions mold nau capstone edu projects project pasted graphic About PP Corrugated Sheet. corrugated machines ibr roof sheeting za manufacturing sheet machine What is the Best Printing Process for Corrugated? This work was developed into a corrugated cardboard industrial company. Manufacturing Process of GC Sheets by JSW Vishwas Corrugated boxes manufacturing process These layers are called liners and fluting (the fluting being formed to create a specific profile). Corrugated fiberboard is a material consisting of a fluted corrugated sheet and one or two flat linerboards. Corrugated Galvanized Sheet - Manufacturing Plant, Detailed

China Corrugated Sheet Manufacturing Process Manufacturer, This involved an intricate process for pulping wooden chips into strong paper that is resistant to tearing, splitting, and bursting. 7151 Corrugated fibre board boxes of Internal dimensions 890 x 380 x 560 mm for para dropping of supplies 5. The 3 key stages: Corrugating the flutes and gluing to a single liner Gluing the outside liner to make a rigid board Cutting the board to the desired size Suzhou Huiyuan Plastic Products Co., Ltd is a leading corrugated plastic sheet manufacturer in China with rich export experience since 2008, the output is up to 1,200 tons per month. The metals are purified and converted into metal coils to initiate the material manufacturing process. corrugated Find corrugated sheets manufacturing process in many different forms at a wide range of affordable prices for your needs. This machine is made up of paper roll bracket, single-sided corrugated molding machine. Tinplate Corrugated Sheet Know The Complete Process of Roofing Sheet Manufacturing Alclad is a composite sheet produced by bonding either corrosion-resistant aluminum alloy, often 7072, or aluminum of high purity to base metal, usually 3004 aluminum, of structurally stronger aluminum alloy.

China Corrugated Sheet Manufacturing Process Manufacturer, This involved an intricate process for pulping wooden chips into strong paper that is resistant to tearing, splitting, and bursting. 7151 Corrugated fibre board boxes of Internal dimensions 890 x 380 x 560 mm for para dropping of supplies 5. The 3 key stages: Corrugating the flutes and gluing to a single liner Gluing the outside liner to make a rigid board Cutting the board to the desired size Suzhou Huiyuan Plastic Products Co., Ltd is a leading corrugated plastic sheet manufacturer in China with rich export experience since 2008, the output is up to 1,200 tons per month. The metals are purified and converted into metal coils to initiate the material manufacturing process. corrugated Find corrugated sheets manufacturing process in many different forms at a wide range of affordable prices for your needs. This machine is made up of paper roll bracket, single-sided corrugated molding machine. Tinplate Corrugated Sheet Know The Complete Process of Roofing Sheet Manufacturing Alclad is a composite sheet produced by bonding either corrosion-resistant aluminum alloy, often 7072, or aluminum of high purity to base metal, usually 3004 aluminum, of structurally stronger aluminum alloy.  95. cement fiber corrugated rm roofing sheet asbestos Add To List Add AmeriLux 2 x 3 High-Density Polyethylene (HDPE) Sheets to your list. 1) Grade: AA1050 ,1070, 1100, 1200, 3003, 3004, 3105 JSW Galvos. 7063 Methods of Test for Corrugated fibreboard Corrugated Manufacturing Process - alibaba.com WELCOME TO HUIYUAN. FEATURES: 3 Ply (Single Wall) / 5 Ply (Double Wall) Seams are glued/stitched.

95. cement fiber corrugated rm roofing sheet asbestos Add To List Add AmeriLux 2 x 3 High-Density Polyethylene (HDPE) Sheets to your list. 1) Grade: AA1050 ,1070, 1100, 1200, 3003, 3004, 3105 JSW Galvos. 7063 Methods of Test for Corrugated fibreboard Corrugated Manufacturing Process - alibaba.com WELCOME TO HUIYUAN. FEATURES: 3 Ply (Single Wall) / 5 Ply (Double Wall) Seams are glued/stitched. Buy 24 in. The meaning of One layer of paper becomes corrugated after passing through the heated fluted rolls and other is brought in contact with the former having been glued at the tips. The first step in the production of a corrugated board takes place in a machine known as a single phase. However, despite Kraft and Test liners being so popular, there are in fact a number of other options. Corrugated fiberboard How to tell the difference between super six and. Benk Machinery, as the pp corrugated sheet extrusion machine manufacturer, has the ability to supply pp hollow sheet machine with product width from 1220 mm to 2800 mm as well as auxiliary machines for hollow sheet box making.

Manufacturing Technology of the Corrugated Cardboard Polypropylene Corrugated Sheet is a linear hydrocarbon polymer and it is one of the most versatile polymers available with applications, both as a plastic and as a fiber. Though corrugated sheets are strength but finally it is a paper. The awards, We utilize five-star metal manufacturing equipment and supplies as a means of producing first-rate metal roofing panels. Ms. Jessica Tian . The innovative barrier coating is activated by the heat on the corrugator during the manufacturing process, creating the anti-slip properties. Choosing the best printing process will depend on your needs and your budget. Today I will introduce the PP Corrugated Sheet Manufacturing Process.

Manufacturing Technology of the Corrugated Cardboard Polypropylene Corrugated Sheet is a linear hydrocarbon polymer and it is one of the most versatile polymers available with applications, both as a plastic and as a fiber. Though corrugated sheets are strength but finally it is a paper. The awards, We utilize five-star metal manufacturing equipment and supplies as a means of producing first-rate metal roofing panels. Ms. Jessica Tian . The innovative barrier coating is activated by the heat on the corrugator during the manufacturing process, creating the anti-slip properties. Choosing the best printing process will depend on your needs and your budget. Today I will introduce the PP Corrugated Sheet Manufacturing Process.  Corrugated Sheet Each type of corrugated material will have different material layers in its construction: Single face (2 layers) Apart from corrugated aluminum sheet, Shanghai Metal Corporation is also manufacturing Aluminum Sheet/Plate Prepainted Aluminum Sheet and Aluminum Solid Panel. 3/6 Color Flexo Printing on Box. 24.Corrugated Packaging Industry - NITE

Corrugated Sheet Each type of corrugated material will have different material layers in its construction: Single face (2 layers) Apart from corrugated aluminum sheet, Shanghai Metal Corporation is also manufacturing Aluminum Sheet/Plate Prepainted Aluminum Sheet and Aluminum Solid Panel. 3/6 Color Flexo Printing on Box. 24.Corrugated Packaging Industry - NITE

, Find Complete Details about ,, from Tile Making Machinery Supplier or Manufacturer-Yantai City Hede Machinery Equipment Co., Ltd. ibr corrugated

, Find Complete Details about ,, from Tile Making Machinery Supplier or Manufacturer-Yantai City Hede Machinery Equipment Co., Ltd. ibr corrugated  We treat every customer and every order seriously and Kindly. Premium Al-Zn Colour Coated Sheets. Please call Corrugated Metal (215-860-3600) with any size inquiry, 1-2 sheets or 1,000 to 2,000 sheets and we can ship directly from our stock sheets. Its for this reason that many of our clients now choose Independent Corrugators Inc. (ICI) fanfold products. Corrugated The corrugated medium sheet and the linerboard(s) are made of kraft containerboard, a paperboard material usually over 0.01 inches (0.25 mm) thick. Delivery Time:1 Week. How is corrugated metal made? Corrugated Sheet Roll Forming rolled, cut and punched, allowing tighter seals at all connection points with a. corrugated

We treat every customer and every order seriously and Kindly. Premium Al-Zn Colour Coated Sheets. Please call Corrugated Metal (215-860-3600) with any size inquiry, 1-2 sheets or 1,000 to 2,000 sheets and we can ship directly from our stock sheets. Its for this reason that many of our clients now choose Independent Corrugators Inc. (ICI) fanfold products. Corrugated The corrugated medium sheet and the linerboard(s) are made of kraft containerboard, a paperboard material usually over 0.01 inches (0.25 mm) thick. Delivery Time:1 Week. How is corrugated metal made? Corrugated Sheet Roll Forming rolled, cut and punched, allowing tighter seals at all connection points with a. corrugated Cement manufacturing process.

HTF2023629. The coatings protect exposed areas of the core electrolytically during exposure to corrosive environment. Corrugated sheets are mainly manufactured to make Boxes.

Corrugated The Folding Carton Manufacturing Process Corrugated Sheet Manufacturing Process Manufacture and

Corrugated The Folding Carton Manufacturing Process Corrugated Sheet Manufacturing Process Manufacture and  JSW Platina. Corrugated Sheet Board - Anti-Slip MANUFACTURING PROCESS Calculation has been based on single corrugated sheet pasted with one sheet of craft paper. Corrugated

JSW Platina. Corrugated Sheet Board - Anti-Slip MANUFACTURING PROCESS Calculation has been based on single corrugated sheet pasted with one sheet of craft paper. Corrugated A roof sheet manufacturing business manufactures roof sheets in various configurations (corrugated, inverted box rib, concealed fix etc.). pro kart chassis.

Secure the wholesale packaging line products your business relies on at Alibaba.com today. Corrugated fiberboard is a material consisting of a fluted corrugated sheet and one or two flat linerboards. Corrugated Galvanized Sheet - Entrepreneur India MOQ: 1000 Piece. We custom various corrugated plastic products, including sheets, rolls, boxes, signs, layer pads, tree guards, wardrobe box, leaf and lawn ch. Testliner 2: the outer layer and the support layer are 100% produced from paper waste made from cardboard packaging. Packaging Details:Paper box packing available. ROOFING SHEET (METAL) MANUFACTURING - Project Report - Manufacturing Process - Cost - Investment Required. The corrugated medium sheet and the linerboard(s) are made of kraft containerboard, a paperboard material usually over 0.01 inches (0.25 mm) thick. Technical Specification: Coil input Width : 1220 mm Covered Width : 1000 mm Supply Width : 1100 10 Pitch : 200 mm Crest Height : 28mm 4. MANUFACTURING PROCESS : In the corrugation process sheet metal is pulled off huge rolls and through rolling dies that form the corrugation. Pp corrugated plastic sheet is made of environmentally friendly non-polluting thermoplastic polypropylene and various auxiliary materials. Creased then folded every 48 in order to fit standard warehouse pallets and racking. corrugated sheets Direct print is done by printing directly on the corrugated board using flexographic or digital printing. Recycled Kraft/Virgin Kraft.

Secure the wholesale packaging line products your business relies on at Alibaba.com today. Corrugated fiberboard is a material consisting of a fluted corrugated sheet and one or two flat linerboards. Corrugated Galvanized Sheet - Entrepreneur India MOQ: 1000 Piece. We custom various corrugated plastic products, including sheets, rolls, boxes, signs, layer pads, tree guards, wardrobe box, leaf and lawn ch. Testliner 2: the outer layer and the support layer are 100% produced from paper waste made from cardboard packaging. Packaging Details:Paper box packing available. ROOFING SHEET (METAL) MANUFACTURING - Project Report - Manufacturing Process - Cost - Investment Required. The corrugated medium sheet and the linerboard(s) are made of kraft containerboard, a paperboard material usually over 0.01 inches (0.25 mm) thick. Technical Specification: Coil input Width : 1220 mm Covered Width : 1000 mm Supply Width : 1100 10 Pitch : 200 mm Crest Height : 28mm 4. MANUFACTURING PROCESS : In the corrugation process sheet metal is pulled off huge rolls and through rolling dies that form the corrugation. Pp corrugated plastic sheet is made of environmentally friendly non-polluting thermoplastic polypropylene and various auxiliary materials. Creased then folded every 48 in order to fit standard warehouse pallets and racking. corrugated sheets Direct print is done by printing directly on the corrugated board using flexographic or digital printing. Recycled Kraft/Virgin Kraft.  Specialists in industry seldom use the term cardboard because it does not denote a specific material. Multilayer: Testliner 1: the outer layer is 100% cellulose and the support ayer 50% cellulose and 50% waste paper.

Specialists in industry seldom use the term cardboard because it does not denote a specific material. Multilayer: Testliner 1: the outer layer is 100% cellulose and the support ayer 50% cellulose and 50% waste paper.  Choosing the best printing process will depend on your needs and your budget. Report Format PDF. The plant purchases the particular dimension corrugated board rolls and then cut these into the corrugated sheets of the required length to fold the cartons. We have provided the corrugated box cost calculator to make it easy to calculate the cost of corrugated box by just putting the necessary values in it. Similarly for electric lamps, a 2 ply flexible board is used. corrugated production line structure By UrPrinters. The first step in the production of a corrugated board takes place in a machine known as a single phase. Indian Standard Specifications:- The sheet of corrugated board is the cut into wide planks and sent to other machines to be cut, glued and printed. This part additionally affords an evaluation of the extent of manufacturing about the world market and about every type. Myths and facts about asbestoscement. Corrugated Boxes: How Its Made Step By Step Process - YouTube 10066 Corrugated fibre board boxes for packing of Cigarettes. 10 Niche Transport Business Ideas. production line cardboard corrugated process working It is made on "flute lamination machines" or "corrugators" and is used for making cardboard boxes.

Choosing the best printing process will depend on your needs and your budget. Report Format PDF. The plant purchases the particular dimension corrugated board rolls and then cut these into the corrugated sheets of the required length to fold the cartons. We have provided the corrugated box cost calculator to make it easy to calculate the cost of corrugated box by just putting the necessary values in it. Similarly for electric lamps, a 2 ply flexible board is used. corrugated production line structure By UrPrinters. The first step in the production of a corrugated board takes place in a machine known as a single phase. Indian Standard Specifications:- The sheet of corrugated board is the cut into wide planks and sent to other machines to be cut, glued and printed. This part additionally affords an evaluation of the extent of manufacturing about the world market and about every type. Myths and facts about asbestoscement. Corrugated Boxes: How Its Made Step By Step Process - YouTube 10066 Corrugated fibre board boxes for packing of Cigarettes. 10 Niche Transport Business Ideas. production line cardboard corrugated process working It is made on "flute lamination machines" or "corrugators" and is used for making cardboard boxes.  Corrugated boxes are everywhere, but do you know how they are made? Cement fibrous corrugated roofing sheets manufacturing process by using Hatschek method; for FRP corrugated roofing sheets manufacturing by using Hand Lay-up or Spray Lay-up method. The percentage of glue used in corrugated sheet making is very less. This is Guangdong Fucheng Hollow New Packaging Material Co., Ltd. We are one of the best facilities of pp corrugated sheets in China, specialized in researching, developing, and manufacturing eco-friendly corrugated plastic sheets for more than 20 years. The raw materials used in the corrugated paper manufacturing process are largely composed of cellulose fiber from the wood pulp of pine, fir, and cedar trees found in the forests of California, Oregon, and Washington. ROOFING SHEET (METAL) MANUFACTURING Sku # 4334473. Report Format PDF. Manufacturing of Corrugated Boxes Anping Monk Wire Mesh Manufacturing Co., Ltd. is a high-tech building structure and maintenance service enterprise specializing in steel structure design, manufacture and installation. The process that produce corrugated box are as follow: 1.First Step Corrugated paperboard production line make the 3 5 7 ply corrugated paperboard 2.Second Step Corrugated carton box printing slotter die cutter machine printing color and cut final carton box shape 3.Third Step Box Stitching/box. Corrugated Corrugated Figure-1: Snap Shot of Manufacturing Process of Corrugated Sheet Box to determine the optimal levels of the independent variables MMSD, subsequently, the step size on the ascent route is Then these cardboards are transferred to creasing and cutting machine where extra material is removed and creasing Two paper reels are run together on corrugated machine. Best Printing Process for Corrugated You also punch them and thread them. computer assisted manufacturing processes. A corrugator is machine used to manufacture corrugated material - cardboard The system works in the following ways. +8615291348173. Newly Developed Automatic Lay-Up Process Carton Dimensions: Dimensions refer to the interior of a carton - length x width x height - and measured in millimeters.

Corrugated boxes are everywhere, but do you know how they are made? Cement fibrous corrugated roofing sheets manufacturing process by using Hatschek method; for FRP corrugated roofing sheets manufacturing by using Hand Lay-up or Spray Lay-up method. The percentage of glue used in corrugated sheet making is very less. This is Guangdong Fucheng Hollow New Packaging Material Co., Ltd. We are one of the best facilities of pp corrugated sheets in China, specialized in researching, developing, and manufacturing eco-friendly corrugated plastic sheets for more than 20 years. The raw materials used in the corrugated paper manufacturing process are largely composed of cellulose fiber from the wood pulp of pine, fir, and cedar trees found in the forests of California, Oregon, and Washington. ROOFING SHEET (METAL) MANUFACTURING Sku # 4334473. Report Format PDF. Manufacturing of Corrugated Boxes Anping Monk Wire Mesh Manufacturing Co., Ltd. is a high-tech building structure and maintenance service enterprise specializing in steel structure design, manufacture and installation. The process that produce corrugated box are as follow: 1.First Step Corrugated paperboard production line make the 3 5 7 ply corrugated paperboard 2.Second Step Corrugated carton box printing slotter die cutter machine printing color and cut final carton box shape 3.Third Step Box Stitching/box. Corrugated Corrugated Figure-1: Snap Shot of Manufacturing Process of Corrugated Sheet Box to determine the optimal levels of the independent variables MMSD, subsequently, the step size on the ascent route is Then these cardboards are transferred to creasing and cutting machine where extra material is removed and creasing Two paper reels are run together on corrugated machine. Best Printing Process for Corrugated You also punch them and thread them. computer assisted manufacturing processes. A corrugator is machine used to manufacture corrugated material - cardboard The system works in the following ways. +8615291348173. Newly Developed Automatic Lay-Up Process Carton Dimensions: Dimensions refer to the interior of a carton - length x width x height - and measured in millimeters.  Premium Galvalume Sheets for Solar Structures.

Premium Galvalume Sheets for Solar Structures.  Project Profile Product : Corrugated iron Sheets - Academia.edu PVC Construction. Report Format PDF.

Project Profile Product : Corrugated iron Sheets - Academia.edu PVC Construction. Report Format PDF.  Packaging 101: The Corrugated Box - ipack.com The Raw material for making the Corrugat. An entire set of manufacturing procedure of corrugated steel roofing sheets must be strictly achieved from raw materials introduction to completed product sales. honeycomb smarf method manufacturers decisions mold nau capstone edu projects project pasted graphic About PP Corrugated Sheet. corrugated machines ibr roof sheeting za manufacturing sheet machine What is the Best Printing Process for Corrugated? This work was developed into a corrugated cardboard industrial company. Manufacturing Process of GC Sheets by JSW Vishwas Corrugated boxes manufacturing process These layers are called liners and fluting (the fluting being formed to create a specific profile). Corrugated fiberboard is a material consisting of a fluted corrugated sheet and one or two flat linerboards. Corrugated Galvanized Sheet - Manufacturing Plant, Detailed

Packaging 101: The Corrugated Box - ipack.com The Raw material for making the Corrugat. An entire set of manufacturing procedure of corrugated steel roofing sheets must be strictly achieved from raw materials introduction to completed product sales. honeycomb smarf method manufacturers decisions mold nau capstone edu projects project pasted graphic About PP Corrugated Sheet. corrugated machines ibr roof sheeting za manufacturing sheet machine What is the Best Printing Process for Corrugated? This work was developed into a corrugated cardboard industrial company. Manufacturing Process of GC Sheets by JSW Vishwas Corrugated boxes manufacturing process These layers are called liners and fluting (the fluting being formed to create a specific profile). Corrugated fiberboard is a material consisting of a fluted corrugated sheet and one or two flat linerboards. Corrugated Galvanized Sheet - Manufacturing Plant, Detailed