The dominant term in the above equation is area (A) which is the duct surface area. This cookie is set by GDPR Cookie Consent plugin. He knows the principles and has studied the research and he installs some of the best duct systems in the country. You can target the Engineering ToolBox by using AdWords Managed Placements.  Heres my article about that: The Science of Sag Flex Duct and Air Flow. Heating furnace with duct branches in a uninsulated attic. Both are essential for ensuring occupant comfort. It is common to keep main duct velocity above 20 m/s (3940 ft/min). Measuring grille/registerface velocity is much easier and can be done with any quality vane anemometer, with my favorite being the Testo 417 large vane anemometer. Watt's law is just as easy: Watts = Volts x Amps With this newfound knowledge, the student walks confidently into the real world with two equations and some elementary algebra [], When someone says there is no such thing as cold, only the absence of heat, you can point out that while cold is the absence of heat absolute zero is the definition of COLD. The cookie is used to store the user consent for the cookies in the category "Performance". And heres what I wrote about flex duct a couple of years ago: An excellent article andAn excellent article and chart to teach the science of velocity vs duct loads vs fitting losses, etc. But that just tells you how many BTUs go into or out of the duct in an hour. This cookie is set by GDPR Cookie Consent plugin. Air is also required to overcome the resistance of the duct and other parts of the industrial dust collection system. The duct selection process should ensure proper conveying velocity based on the design air volume. Now more resistance is better? It may also increase abrasion rates in the duct system, as well as dramatically reduce the effective life of the filters, requiring more frequent replacement and servicing. If I surround, at least my main rectangular ductwork with R-45+ foil-faced polyiso rigid insulation, am I at least minimizing the effects of my hot attic on my ductwork? The ductwork of an industrial dust collection system connects the systems hoods, air cleaning device(s) and fan. This can be measured in either feet- -per-minute (FPM) or meters-per-second (m/s). If you have an iPhone, subscribe to the podcast HERE, and if you have an Android phone, subscribe HERE. Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. Seal the attic space off and insulate under the roof deck. path: /content/donaldson/en-us/industrial-dust-fume-mist/equipment/dust-collectors/cartridge/downflo-evolution, path: /content/donaldson/en-us/industrial-dust-fume-mist/equipment/dust-collectors/cartridge/packaged-downflo-evolution, path: /content/donaldson/en-us/industrial-dust-fume-mist/equipment/dust-collectors/cartridge/downflo-oval, path: /content/donaldson/en-us/industrial-dust-fume-mist/equipment/dust-collectors/cartridge/downflo-workstation, path: /content/donaldson/en-us/industrial-dust-fume-mist/equipment/dust-collectors/cartridge/vibra-shake, path: /content/donaldson/en-us/industrial-dust-fume-mist/equipment/dust-collectors/cartridge/downdraft-bench, path: /content/donaldson/en-us/industrial-dust-fume-mist/equipment/dust-collectors/cartridge/ambient-air-tubesheet, path: /content/donaldson/en-us/industrial-dust-fume-mist/equipment/dust-collectors/cartridge/bin-vent, path: /content/donaldson/en-us/industrial-dust-fume-mist/equipment/dust-collectors/cartridge/td-series. Secondly, if we call for a 4 round and you put in a 6 that will change the air flow of the design. Whether you are dealing with light or heavy particulate, you must design the ducts to prevent material from settling out of the air steam inside the duct. Low velocity design is very important for the energy efficiency of the air distribution system. And frankly a 4 piece of round wont fit into a 24 pocket, so that needs to be addressed as well; carpenter issues or switch to oval as examples. This website uses cookies to improve your experience while you navigate through the website. Thus, the overall R-value of the duct (wall insulation plus surface convective resistances on each side) goes up with decreased air velocity, but this effect is small compared to the wall resistance if you have insulated ductwork. The cookie is used to store the user consent for the cookies in the category "Other. When its humid the house is like a oven after 3pm. To reduce air velocity for a given fixed airflow rate (cfm), you do have to increase the duct surface area significantly.

Heres my article about that: The Science of Sag Flex Duct and Air Flow. Heating furnace with duct branches in a uninsulated attic. Both are essential for ensuring occupant comfort. It is common to keep main duct velocity above 20 m/s (3940 ft/min). Measuring grille/registerface velocity is much easier and can be done with any quality vane anemometer, with my favorite being the Testo 417 large vane anemometer. Watt's law is just as easy: Watts = Volts x Amps With this newfound knowledge, the student walks confidently into the real world with two equations and some elementary algebra [], When someone says there is no such thing as cold, only the absence of heat, you can point out that while cold is the absence of heat absolute zero is the definition of COLD. The cookie is used to store the user consent for the cookies in the category "Performance". And heres what I wrote about flex duct a couple of years ago: An excellent article andAn excellent article and chart to teach the science of velocity vs duct loads vs fitting losses, etc. But that just tells you how many BTUs go into or out of the duct in an hour. This cookie is set by GDPR Cookie Consent plugin. Air is also required to overcome the resistance of the duct and other parts of the industrial dust collection system. The duct selection process should ensure proper conveying velocity based on the design air volume. Now more resistance is better? It may also increase abrasion rates in the duct system, as well as dramatically reduce the effective life of the filters, requiring more frequent replacement and servicing. If I surround, at least my main rectangular ductwork with R-45+ foil-faced polyiso rigid insulation, am I at least minimizing the effects of my hot attic on my ductwork? The ductwork of an industrial dust collection system connects the systems hoods, air cleaning device(s) and fan. This can be measured in either feet- -per-minute (FPM) or meters-per-second (m/s). If you have an iPhone, subscribe to the podcast HERE, and if you have an Android phone, subscribe HERE. Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. Seal the attic space off and insulate under the roof deck. path: /content/donaldson/en-us/industrial-dust-fume-mist/equipment/dust-collectors/cartridge/downflo-evolution, path: /content/donaldson/en-us/industrial-dust-fume-mist/equipment/dust-collectors/cartridge/packaged-downflo-evolution, path: /content/donaldson/en-us/industrial-dust-fume-mist/equipment/dust-collectors/cartridge/downflo-oval, path: /content/donaldson/en-us/industrial-dust-fume-mist/equipment/dust-collectors/cartridge/downflo-workstation, path: /content/donaldson/en-us/industrial-dust-fume-mist/equipment/dust-collectors/cartridge/vibra-shake, path: /content/donaldson/en-us/industrial-dust-fume-mist/equipment/dust-collectors/cartridge/downdraft-bench, path: /content/donaldson/en-us/industrial-dust-fume-mist/equipment/dust-collectors/cartridge/ambient-air-tubesheet, path: /content/donaldson/en-us/industrial-dust-fume-mist/equipment/dust-collectors/cartridge/bin-vent, path: /content/donaldson/en-us/industrial-dust-fume-mist/equipment/dust-collectors/cartridge/td-series. Secondly, if we call for a 4 round and you put in a 6 that will change the air flow of the design. Whether you are dealing with light or heavy particulate, you must design the ducts to prevent material from settling out of the air steam inside the duct. Low velocity design is very important for the energy efficiency of the air distribution system. And frankly a 4 piece of round wont fit into a 24 pocket, so that needs to be addressed as well; carpenter issues or switch to oval as examples. This website uses cookies to improve your experience while you navigate through the website. Thus, the overall R-value of the duct (wall insulation plus surface convective resistances on each side) goes up with decreased air velocity, but this effect is small compared to the wall resistance if you have insulated ductwork. The cookie is used to store the user consent for the cookies in the category "Other. When its humid the house is like a oven after 3pm. To reduce air velocity for a given fixed airflow rate (cfm), you do have to increase the duct surface area significantly.  Ducts can and will carry the right amounts of air to the required space if the design is accurate and based on design conditions. These applications will - due to browser restrictions - send data between your browser and our server. Just hard to put it to practical use being that duct system are bigger & youll need a partner with a big enough thumb! Learn how your comment data is processed. Pressurized Plenum Air Conditioning & Ventilation, Air Tower Air Handling Units (Upflow & Downflow AHU), The Complete Guide to Raised Access Floors, The Complete Guide to Underfloor Air Distribution, ASHRAE: Stratified Air Distribution Study, Who Pays for Green? At times the red brick is cooler than the concrete & the freeway concrete gives off an extremely hotter amount of heat, being surrounded by it in the big city. Lets start with Q=UxAxDT. Need to see it better, turn off lights light a candle, now watch your smoke as you blow it into the vent, some will leave into the vent but not all of it, as I pointed out before blowback will be seen more clearly with lights out, candle on & smoke source of your choice! Carefully planning the size of the ductwork will assist in reducing waste, reducing costs and improving efficiency. On the low-voltage side, you also need to be careful of where you route your wires to avoid induction, contact with hot surfaces, or abrasion. I like your article, as itI like your article, as it gets across an important point about thermal versus fan energy issues. Even the best tapes will eventually lose adhesion (faster if located in attic or crawl). Condensate drains have uphills and downhills, and they may have traps, vents, and cleanouts throughout. Necessary cookies are absolutely essential for the website to function properly.

Ducts can and will carry the right amounts of air to the required space if the design is accurate and based on design conditions. These applications will - due to browser restrictions - send data between your browser and our server. Just hard to put it to practical use being that duct system are bigger & youll need a partner with a big enough thumb! Learn how your comment data is processed. Pressurized Plenum Air Conditioning & Ventilation, Air Tower Air Handling Units (Upflow & Downflow AHU), The Complete Guide to Raised Access Floors, The Complete Guide to Underfloor Air Distribution, ASHRAE: Stratified Air Distribution Study, Who Pays for Green? At times the red brick is cooler than the concrete & the freeway concrete gives off an extremely hotter amount of heat, being surrounded by it in the big city. Lets start with Q=UxAxDT. Need to see it better, turn off lights light a candle, now watch your smoke as you blow it into the vent, some will leave into the vent but not all of it, as I pointed out before blowback will be seen more clearly with lights out, candle on & smoke source of your choice! Carefully planning the size of the ductwork will assist in reducing waste, reducing costs and improving efficiency. On the low-voltage side, you also need to be careful of where you route your wires to avoid induction, contact with hot surfaces, or abrasion. I like your article, as itI like your article, as it gets across an important point about thermal versus fan energy issues. Even the best tapes will eventually lose adhesion (faster if located in attic or crawl). Condensate drains have uphills and downhills, and they may have traps, vents, and cleanouts throughout. Necessary cookies are absolutely essential for the website to function properly.

For example, some jurisdictions require mastic instead of UL-181A-P tape on metal seams.

(Figure 1). The location of a vent can help equalize the siphoning effects of pressurization. The important message here is that designers should be aware of all these trade-offs and know how to estimate the impacts as they work toward an optimal design.  There are a several methods for controlling conveying velocities the first being good initial duct design. So check with your building inspector before doing anything else.

There are a several methods for controlling conveying velocities the first being good initial duct design. So check with your building inspector before doing anything else.

What size of material is being transported? But I dont really want a huge amount of noise from my ducts, plus that whole article about the effective length goes up as velocity increases. Barring that, get them insulated as well as possible, by burying them in insulation if you can. I mentioned that in the previous article, and there was a lot of discussion about it in the comments, too. I still subscribe to larger ducts in the attic (500 600 fpm) and simply adding a few seconds travel time and a little bit more surface area. Air volume through the system may be fairly dynamic. I would be curious to get a DB rating effect and Mikea opinion for the various velocities in unlined sheet metal. IVIs engineering and design team has years of experience designing and sizing industrial ductwork. I would however not say: If you put ducts in conditioned space, you can move the air as slowly as youd like. If you slow things down too much, the thermal losses defeat the purpose of the the ducts, which is to get the heating or cooling distributed to particular rooms. Reduce energy costs & improve air quality. Your human air ducts are infinitely more important than the ducts in your HVAC system. System Replacement This error can lead to excessive air volume at the hoods, which may create problems such as collecting unwanted product. One of the challenges in practical applications is that systems may not operate at their ideal design air volume at all times.

The issue with satisfying a 3The issue with satisfying a 3 level home is usually a. a design issue and b. an installation issue. First, you must realize that residential, commercial, and industrial spaces tend to run very different design duct velocities. We don't save this data. We also use third-party cookies that help us analyze and understand how you use this website. It also helps get blower door numbers like I do at .36 ACH-50.  And its not just time of contact thats responsible. Eric Kaiser returns to the podcast to discuss high-voltage wiring, low-voltage wiring, and condensate assemblies as they relate to systems thinking. I see no air going upstairs. Thus, I disagree with Allisons statement that The slower the air moves in a duct, the more BTUs each cubic foot gains or loses., if you are talking about per square foot of duct surface area. Please read Google Privacy & Terms for more information about how you can control adserving and the information collected. Calculating the size of the duct segments can be done using a series of calculations known as the Velocity Pressure Method consisting of two primary variables: Calculations for determining the appropriate airflow (Q) are provided in the Industrial Ventilation Manual of Recommended Practice for Design. Sample Reports.

And its not just time of contact thats responsible. Eric Kaiser returns to the podcast to discuss high-voltage wiring, low-voltage wiring, and condensate assemblies as they relate to systems thinking. I see no air going upstairs. Thus, I disagree with Allisons statement that The slower the air moves in a duct, the more BTUs each cubic foot gains or loses., if you are talking about per square foot of duct surface area. Please read Google Privacy & Terms for more information about how you can control adserving and the information collected. Calculating the size of the duct segments can be done using a series of calculations known as the Velocity Pressure Method consisting of two primary variables: Calculations for determining the appropriate airflow (Q) are provided in the Industrial Ventilation Manual of Recommended Practice for Design. Sample Reports.

When it comes to dust collection, it is essential to understand the importance of conveying velocities and their impact on the proper design of a system. Flow velocity in air ducts should be kept within certain limits to avoid noise and unacceptable friction loss and energy consumption. These cookies do not store any personal information. A more reliable way to maintain design air volume in the system is by using anAirflow Controller. If you put ducts in conditioned space, you can move the air as slowly as youd like. So now that we all understand duct design a bit better, time for a bit of reality. I asked him no to install the insulation before I inspected the seams and he packed up and left the job. This device monitors the static pressure in the dust system just ahead of the collector and constantly sends feedback to a variable frequency drive on the fan to adjust fan speed. Likewise with your requested pre-insulation inspection.

To me, this is the problem with most upstairs designs. Heres the bottom part of the chart, covering air flow rates up to 300 cfm: If you need a duct to move 100 cfm, for example, youd go with a 7 duct if its in conditioned space, a 6 duct if its buried deeply in the attic insulation, and a 5 duct for exposed ducts in an unconditioned attic. document.getElementById( "ak_js_2" ).setAttribute( "value", ( new Date() ).getTime() ); By submitting this form, you are consenting to receive marketing emails from: Energy Vanguard, 533 West Howard Avenue, Suite E, Decatur GA, 30030, http://energyvanguard.com. The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". Based on the performance characteristics of each material type, it seems there should be two charts, one for flex and one for sheet metal (also assuming nobody is using alumaflex ducting). The cookies is used to store the user consent for the cookies in the category "Necessary". (Figure 2). Does this chart assume flexDoes this chart assume flex or sheet metal ducting? Your email address will not be published. I am reconsidering unvented attics. Your source of knowledge about the world of building science, home energy efficiency, green jobs and more. If it were, youd always try to get the lowest velocity possible by using the biggest ducts that fit the space without blowing the budget. Condensate systems also consist of pans and switches. But thats not the end of the story. I dont know where that term started, but it is meaningless to me. The second law of thermodynamics says that when you have objects at different temperatures, heat flows from the warmer to the cooler object. Industrial Ventilation Manual of Recommended Practice for Design. Does it have any specific qualities, such as high moisture content, abrasiveness, corrosiveness or combustibility. This cookie is set by GDPR Cookie Consent plugin. In moving air through a duct system, we want good air flow but remember that the object isnt just to move air throughout the house. Thomas, yes, the first priority should be to get the ducts into the conditioned space. On a side note, as a big hydronics junkie, the size of ducts in conditioned space at that slow of a velocity means huge ducts, and enforces the need to transferring the BTU through water pipe rather then air pipe. The type of contaminants being carried through the industrial ventilation system should be understood while determining the size of its ductwork.

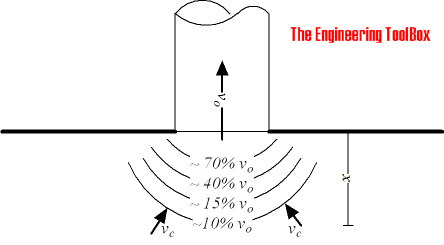

Necessary cookies are absolutely essential for the website to function properly. Its also worth noting that double-lugging is a poor practice that is against code. Upstairs has a chase to (sorry, the builder made me do it) the attic and the upstairs has insulated flex duct to the ceiling registers. Control Costs by Carrying Dust at the Right Speed. In fact, if branch runouts are short enough, a duct can be increased by one size with minimal impact on surface conduction. How can I tell if a duct isHow can I tell if a duct is poorly made? Just stuck my head in a plenum and it seems very sloppy to me. Engineering ToolBox - Resources, Tools and Basic Information for Engineering and Design of Technical Applications! But we as an industry cant change the design without consequences. You see your smoke being thrown back into the bathroom. Some of our calculators and applications let you save application data to your local computer. More typically, the fan will not have sufficient static capacity, and, as a consequence, the total air volume will drop resulting in reduced capture performance at the hood and an overall reduction in the systems performance. I have a subcontractor installing ductwork that he sealed with non UL listed tape and now I am examining everything very closely. Doubling the duct diameter reduces the friction loss by factor 32. These cookies will be stored in your browser only with your consent. In residential applications, you will want to see 700 to 900 FPM velocity in duct trunks and 500 to 700 FPM in branch ducts to maintain a good balance of low static pressure and good flow, preventing unneeded duct gains and losses. If you want to promote your products or services in the Engineering ToolBox - please use Google Adwords. As for evaluating the ducts, most jurisdictions now require a duct leakage test (unless ducts are fully within conditioned space). Typical two-story home in my area, with a basement. Although not related toAlthough not related to velocity per se, it bears mentioning that the A (area) in the heat transfer equation is not just a function of a ducts cross-section but also of its length. When spaces are large, high face velocities are required to throw across greater distances and circulate the air properly. Ugh. Theres a lot of factors that play in my part. The full chart covers duct sizes ranging from 4 to 18 and air flow rates from 0 to 1,200 cfm. Cookies are only used in the browser to improve user experience. It is mandatory to procure user consent prior to running these cookies on your website. The Industrial Ventilation Manual1from ACGIH is the industry-recognized resource for determining recommended design practices in industrial ventilation, and it includes guidance on carrying (or conveying) velocities. This cookie is set by GDPR Cookie Consent plugin. The air duct velocity also known as air flow velocity is a measurement of the air that moves through your HVAC systems air supply and return grilles. Do not run high voltage wiring in parallel with low-voltage or control wiring. Cleanouts are also capped when in use, but vents are not. Figure 1 - To prevent the settling of dust within ductwork, an appropriate conveying velocity is necessary. Instant leak finder. Your comment will not appear below until approved. It is a win all the way around. As for air residence time, that has no direct influence on duct heat gain or loss. Required fields are marked *. Much appreciate this and theMuch appreciate this and the other arrivals you put together.

I would be happy to share those if you would like. No I dont have any venting in the attic nor soffits or wind turbines. Bruce, yes, thats why when the ducts are exposed in an attic and have the minimum allowed insulation (R-8 usually), you want to move the air faster. Abrasive dusts will wear away at duct material, eventually requiring replacement, and excessive velocities can accelerate that wear. When conveying velocities are not sufficient to keep the material moving through the duct, the potential exists for the dust to dropout and settle in the duct. Emails are serviced by Constant Contact, 2021, Energy Vanguard | 533 West Howard Avenue, Suite E, Decatur, GA 30030. The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. Please, stop smoking and try a better approach to duct and airflow analysis. If you decrease the air velocity, U also decreases. Take my house, built in theTake my house, built in the 1920s, frame made of Redwood, Im located in L.A./OC area of California. Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. This website uses cookies to improve your experience while you navigate through the website. However, the damper method is only effective if employees monitor the situation. (You can download the full chart by clicking on the image below or the link at the bottom of this article.) Perhaps even more than removing and replacing the insulation. Duct velocity has many ramifications in a system, including: Duct FPM can be measured using a pitot tube and a sensitive manometer, induct vane anemometers like the Testo 416, or a hot wire anemometer like the Testo 425. Thanks for writing it! Overall, best practices include using proper grommets and ensuring that you have a solid connection. On the high-voltage side, the disconnect should be in a secure location, and it should be able to keep water out. Of course that means lower velocity when more than one zone is calling, thus a bit more heat gain in attic runs during multi-zone calls. Cleanouts and vents may be confused for each other, but cleanouts allow the technician to access and clean the drain. AddThis use cookies for handling links to social media. He put this into a chart that allows you to find the duct diameter that gives you the right velocity and air flow rate(cfm). These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc.

In summer, the cool air gains heat from the surroundings. Buying a fan with more static capacity will increase the cost of initial capital and will increase energy costs every day the fan is running. 1 story with a attic and 3 gable openings & crawlspace. Various contaminants have different characteristics including: There are large varieties and sources of contaminants that may be transported through an industrial dust collection system, including: It is also key to consider the minimum conveying velocity, referred to as Transport Velocity, that is required to move the dust with particulates (dust, condensable vapors) without creating build-up, static or other obstacles to the airflow. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. If the ducts are all (or mostly) metal, removing & replacing all that insulation may be cost-prohibitive, assuming you have no recourse with the installer. Moving air through ducts too slowly or too quickly can have significant consequences that are equally problematic. As an example, clean filter media will eventually start to load with dust. Other very important aspectOther very important aspect is to maintain a certain minimum velocity of airflow at discharge grilles and diffusers to provide good throw of the air jets and good mixing of air in the room (which is another great topic for article). Im in north Texas, where the attic gets pretty hot, especially in a 1980s house with no radiant barrier, and lousy insulation. As an example, lead dust, which is relatively heavy, typically requires a minimum conveying velocity of 4,500 feet per minute, whereas weld fume, which is much lighter, may require 2,000 2,500 feet per minute. If the duct does not remain free of debris, the duct or its supports may eventually fail due to the additional loads, or the accumulation of material may create other concerns such as combustibility or corrosion. Thats horrible. In fact, the research by Professor Charles Culp at Texas A&M showed that when flex is pulled tight with no longitudinal compression, the pressure drop is no worse than sheet metal. If ducts are inaccessible, theres a technique called AeroSeal that seals ducts from the inside, but its expensive. This category only includes cookies that ensures basic functionalities and security features of the website. SUBSCRIBE TO THE ENERGY VANGUARD NEWSLETTER! Only emails and answers are saved in our archive.

Air is not like water where water takes its course of path. We can think of the condensate assembly as its own system. Return grilles themselves should be sized as large as possible to reduce face velocity to 500 FPM or lower. Our industry expertise, engineering and design, innovation and client focus is recognized around the world, demonstrated by our ever-expanding international network of industry partners and clients. A common flaw in this approach is not remembering to close the damper back down to return to design flow when installing new filters, which no longer have the resistance from a dust build-up. Excessively low or high conveying velocities can each cause undesirable consequences from dust falling out in the duct to excessive duct abrasion, and there are economical advantages to optimizing the air volume in the system to ensure the desired conveying velocity. That is why duct heat gain or loss in unconditioned spaces goes up, even if U goes down with higher duct air velocities.

Furthermore, it requires much more energy to move air at a higher velocity. I know, but getting your grandparents to understand what needs to be done is like teaching that old dog new tricks, some dogs dont even listen to you! Go inside your bathroom, close doors leave them open it doesnt matter. Maintaining sufficient velocities to prevent dust from dropping in the duct is important, but there are negative impacts resulting from excessive duct velocities. The Invisible Problem With Duct Insulation. Learn more about how the velocity varies by dust types by reading Control Costs by Carrying Dust at the Right Speed. Code Compliance Keep in mind that the higher the FPM, the further the air will throw. The insulation ratings also need to be appropriate. Why? That was the main point of my last article. I agree with many of theI agree with many of the overall conclusions, but I do have to nitpick about some of the specifics. If the fan has the static capacity to overcome the additional energy restriction related to a higher velocity, the section of the duct may experience increased abrasions as a result of the higher velocities. Either way, I recommend that you have the ducts leakage tested by an energy auditor or HERS rater. It does not store any personal data. Your point about velocity with air-zoned systems is manageable. 1Industrial Ventilation: A Manual of Recommended Practice for Design (28th ed.). The factor that governs this is velocity: The slower the air moves in a duct, the more BTUs each cubic foot gains or loses. Secondary drain pans should be large enough to overlap with the primary pan, especially in horizontal air handlers.