Typical Applications to improve mechanical properties, heat and chemical resistance or processability depending on the demand of end-use and application requirement. Huntsman Advanced Materials is the industry-leader in the custom formulation and manufacturing of aminoamine, modified amine & polyamide curing agents. In addition, nylon polyamide exhibits very good chemical resistance and is an especially oil resistant plastic. Solvay Specialty Polymers Torlon high performance polymer is a polyamide-imide, with the general structure: Figure 1: Structure of Polyamide-imide O O N N H Ar O The variety of applications requiring high temperature resistance, high strength, and the economies of injection-molding has led to the commercialization of several Torlon The most popular type is nylon 6/6, followed by nylon 6, then nylon 6/12, nylon 11 and nylon 12. Its resistance to dilute acids is not so good.

polyamide 6.6 (PA 66) is obtained by reaction of adipic acid with hexamethylenediamine. Power Adhesives Tec 7785 is a high temperature chemical resistant polyamide adhesive. Polyamide nanofibers have properties such as good chemical resistance, very good strength and hardness, high wear resistance, and high surface area to volume ratio, and they are porous, just to name a few. A = No Attack, possibly slight absorption.

Chemical resistance data from immersion tests cannot be unconditionally applied to thermoplastic piping components subjected to continuous or frequent mechanical or thermal stresses.

Chemical resistance data from immersion tests cannot be unconditionally applied to thermoplastic piping components subjected to continuous or frequent mechanical or thermal stresses.

CPVC Because it is BPA free, it is also a useful BPA-free alternative to polycarbonate frequently used for making component parts for medical, biological and Polyamides exhibit high temperature and electrical resistance. Thanks to their crystalline structure, they also show excellent chemical resistance. They have very good mechanical and barrier properties. In addition, these materials can easily be flame retarded. Polyamides became the first truly synthetic fiber to be commercialized.

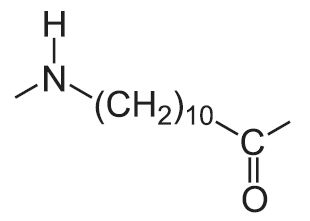

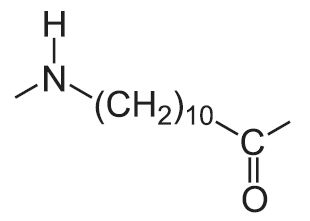

PA - Polyamide (PA 6, PA 6.6, PA 11, PA 12) Polyamides are long chain polymers containing amide units (N-H- C=O). Material will have limited life. Not resistant to ozone, hydrochloric acid, sulphuric acid and hydrogen peroxide. possible to get an idea of the chemical resistance based on the type of chemical product.

Advertisement. It has a high chemical resistance compared with traditional polymers. PEEK also emits low smoke and toxic fumes when exposed to flame, increasing its high-temperature applications.

Based on this success, and leveraging GENESTAR 's unique characteristics, Kuraray now seeks to It offers high impact strength, high dimensional properties such as high chemical resistance, wide application temperature range, good UV resistance (i.e. Polyamide-imide (PAI) resins are thermoset ultra-polymers that are robust, chemical resistant and thermally stable. Polyimides are generally thermosetting polymers; however, thermoplastic polyimides can be obtained by introducing large cyclic side groups to the polymer chain [2]. MOMENTIVE. MOMENTIVE. Properties of Unfilled and Reinforced Polyamide-imides (PAI) 8.4.3 PAIs Chemical Resistance and Sterilization PAIs are resistant to most dilute acids and bases and most organic solvents ( Table 8.2 ). VALLADYN PA612 offers excellent melt stability, barrier properties, dimensional stability, low moisture absorption, and chemical resistance. Ultimately, the consumer must determine the chemical compatibility of an item based on the conditions in which the product is being used. chemical stability and the potential for high strength and modulus. They have outstanding thermal, mechanical, and chemical properties and are often the best choice for demanding applications where very high mechanical strength, stiffness and low friction in combination with high temperature, The global polyamide market size was valued at USD 33.30 billion in 2020 and is expected to expand at a compound annual growth rate (CAGR) of 6.2% from 2021 to 2028. There is a longstanding and widespread interest in designing novel polymer networks, and utilization of ionic liquids (ILs) opens up new frontiers to meet this challenge by creating new materials. With the chemical properties of plastic varying significantly, chemical resistance is influenced by the polymer used for a particular application and the chemicals used within that application.

Thermosetting polymers are widely used as industrial materials due to good heat resistance, dimensional stability and chemical resistance.

Concen- tration % at temp. If the chemistry of polymer molecules were different from that of simple compounds resembling the repeating units (model compounds), the study of the chemical resistance of organic polymers would be difficult.

Nylon 6,6; Nylon 6,12; Nylon 4,6; Nylon 6; Nylon 12 etc. Polyamide-imides are either thermosetting or thermoplastic, amorphous polymers that have exceptional mechanical, thermal and chemical resistant properties. Chemical Resistance. B = Good -- Minor Effect, slight corrosion or discoloration. chemical resistance. Nylon is probably the costliest of the ordinary thermoplastics. VIP-Polymers Ltd. 15 Windover Road, Huntingdon, PE29 7EB, UK Tel: +44 (0) 1480 411333 Fax: +44 (0) 1480 413991 Email: [emailprotected]polymers.com www.vip-polymers.com Chemical Compatibility Guide A=Excellent, B=Good, C=Fair, X=Not Recommended, Blank=Insufficient Information 1 Isse 2.0 Chemical SBR EPDM NBR FKM FFKM Acetaldehyde - B X X A Polyamides are among the most important and useful technical thermoplastics due to their outstanding wear resistance, good coefficient of friction, and very good temperature and impact properties. of the polymer, suitable for coupling. PEEK maintains stiffness at high temperatures and is suitable for continuous use up to 170C (338F). This process is a bit different from a chemical attack since it doesn't affect the molecular structure of the polymers. Rating Scale: 1= Little or no impact 2= Minor effect 3= Moderate effect 4= Severe effect Both are tough and have resistance to abrasion. Tabla 2. [www.corzancpvc.com] Available for the majority of our product lines.

Both are tough and have resistance to abrasion. Tabla 2. [www.corzancpvc.com] Available for the majority of our product lines.

Advertisement.

A polyamide epoxy is a polymer that employs a polyamide resin as a curing agent. View Freelin-Wade's chemical resistant plastic tubing options available now! SABICs polymers portfolio is organized largely around the automotive, foam/lightweight and pipe segments, helping find the right alternatives to replace traditional materials wood, cotton or glass used in a vast array of consumer and industrial products. PERMACOAT 5000, PERMATEC 5000, PERMACAST 5000.

Having marked present according to the most . Description. High viscosity polyamide at 70% weight solids in xylene, offers long pot life. 1 Introduction; 2 Sources. resistance typical of fluorocarbon polymers.

resistance typical of fluorocarbon polymers.

Generic Description Polyamide Epoxy; Its enhanced chemical resistance and physical properties make it an excellent, cost-effective choice for corrosion control in tanks handling brine water, drilling mud, mild temperature backflow, and a wide range of chemicals used in the oil and gas industry. Negligible effect on mechanical properties. These chemical and environmental resistance ratings for thermoplastics are provided for comparison purposes only. Inadequate chemical resistance will reveal itself through material cracking, swelling, softening, discoloration and shortened service life.

Among the many polyamide types, nylon 6 and nylon 6/6 are the cheapest. Naval specification Mil-P-24441A(SH) RECOMMENDED: HIGHLY RECOMMENDED: (1) Other applications include adhesives, electrical castings, electrical laminates and fibers Like PEIs, PAIs are capable of steam sterilization for up to 100 cycles.

Nylon is used in the production of film and fibre, but is also available as a moulding compound.

Corrosion of metals results in a gradual loss of surface material as a result of electrolytic action by the relevant chemicals.

Synthetic Anti-infective Drugs. High viscosity polyamide at 70% weight solids in xylene, offers long pot life. Added consideration must be given to pump selections when the chemical is abrasive, viscous in nature, or has a Specific Gravity greater than 1.1. Get detailed information about chemical resistance of various plastics to hydrogen peroxide @ 30%, 60C with its other important information. l Moderate chemical resistance l: High impact strength Typically used for safety shields: SciLabware Limited, Unit 4, Riverside 2, Campbell Road, Stoke-on-Trent, Staffordshire, ST4 4RJ, wUK +44 (0) 1782 444406: This technical information is provided in Chemical Resistance or Substance Opposition: Cast polyamides provide superior protection against synthetics as compared to wires and connections in severe environments. Aptalon M8100 Polyamide Polyurethane is designed to deliver very high performance topcoats for paint and coating applications. Chemical Compatibility Plastic Material Chart for PA66, PEEK, PPS, 3-(2-Aminoethylane ) -3Aminopropyl trimethoxysilane. Synthetic Anti-infective Drugs.

With high heat resistance, this plastic resin is suitable for high-temperature applications. Leading Provider. PAI (Polyamide-imide) PAI is another high-performance thermoplastic with high-temperature resistance, high thermal stability, good chemical resistance, and supreme wear properties with temperatures up to 275C. EPIKURE 3125A. Good to excellent resistance to greases, oils, fuels, hydraulic fluids, and many solvents as well as to salt solutions and other chemicals. The name "nylons" refers to the group of plastics known as polyamides. Medium viscosity polyamide, provides non- critical combining ratios, toughness, flexibility, corrosion- and water- resistance. However, it does seriously affect the physical structure of the plastic part. Adhesives / Sealants: Epoxy Polyamide cured systems impart good wetting of the substrates giving good adhesion, water and chemical resistance. PVC Polyvinyl Chloride - Chemical Resistance - Chemical resistance of Polyvinyl Chloride PVC. Other factors influencing chemical resistance include the reagent, reagent concentration, temperature, exposure time and whether the polymer is under stress. Polyamide 12 is a polymer from an extremely versatile petrochemical origin, with features that can vary from rigid, with Elastic Moduli of around 1400MPa, to super flexible with Elastic Moduli of around 250MPa.In addition, its affinity with olefinic rubbers allows it to have optimal resistance to low temperatures. Polyimide Physical Properties - Chemical Resistance ot Days 365 23cc 365 @ 230C 365 @ 230 365 @ wc 5 @ % ot Tensile % ot Elongation Resistance To: Benzene Toluene Methanol Aceton e Sodium Hydroxide Transformer Oil Water pH = I pH 10 Degrades Degrades 180 @ 150'C 150ac 1 oooc 230 14 166 @ Polyester, Acrylic, Polyamide & Aramyd

It features a low surface tension, second lowest compared to fluorine polymers, giving it excellent release-ability against various materials.

Medium viscosity polyamide, provides non- critical combining ratios, toughness, flexibility, corrosion- and water- resistance. Polyamides are prone to oxidation and yellowing in sunlight. Reagens PA 6 PA 6 PA 12 PU PP PVC SI* TPE NBR. Other Chemical Drugs. Acetaldehyde, hydrous 40 20 o o + + - o 20C o Acetic acid 10 20 o o o - + + o + - Acetic acid pure 100 20 o o Polypropylene, Polyvinyl, Politetrafluoro-Etilenica, Glass & Cotton. Explore chemical resistance & polymer properties of many engineering plastics. cyclohexane), fats and oils, and to solvents of medium polarity (methyl ethyl ketone) and high polarity (isopropanol).

COMPANY WITH QUALITY SYSTEM CERTIFIED BY DNV GL = UNI EN ISO 9001:2015 = It absorbs little water and as a result its mechanical properties and high dimensional stability change little when exposed to fluctuating environmental humidity. CPVC Corzan is a highquality and durable - compound of CPVC, which outlasts most other CPVC compounds. 1994. It possesses moderate resistance to most of the halogenated hydrocarbons. [www.corzancpvc.com] Available for the majority of our product lines. Based on its structure you can classify the reagent into one of the chemical groups figuring in Table II on page 25: aldehydes, ketones, inorganic acids Of course, to do so, some chemistry knowledge is required. The data below shows PVDF chemical resistance results for both our homopolymer and copolymer 3D printing filaments. This information is intended is intended as a guide only. There are several types of coatings pipe such as fiberglass, polymers and elastomers, but the fluoropolymers In certain environments, the chemical resistance of standard epoxies and urethanes just won't cut it. Polyamide Polyamide Polyamide Thermoplastic Polypropylene % +C Polyurethane Reagent PA 6 PA 66 PA 12 PU PP Ethylene oxide, liquid 100 20 o Ferric cyanide, hydrous saturated 60 + Ferrous chloride, hydrous, indiff. Kevlar is similar in structure to nylon-6,6 except that instead of the amide links joining chains of carbon atoms together, they join benzene rings. The polymer, however, may be attacked by saturated steam, strong bases, and some high-temperature acid systems. Nervous System Drugs. Broad chemical resistance includes strong acids and most organics. Polyamides have several advantages over other classes of engineering polymers. Table 1. Chemical Properties. of Industrial Flooring. Longer durability Unique mechanical properties at various temperatures and low permeability make Technyl grades the materials of choice for applications where long service life is a vital factor.

Ensinger Special Polymers, Inc. 12331 Cutten Road, Houston, TX 77066 Tel: 281-580-3600 Chemically resistant to many acids, oxidizing / reducing agents, neutral and acid salt solutions, greases, oils, detergents, saturated, aliphatic and cycloaliphatic hydrocarbons and alcohols. Digestive System Drugs. PA1010 is semicrystalline, which is the reason for its high mechanical resistance and chemical stability.

Excellent wear resistance When blended with internal lubricants, offers excellent tribological properties.

Fluid, Electrolyte, and Acid-base Balance.

Polyamideimides (PAIs) are high performance amorphous engineering thermoplastics of yellow to brown color. A polyamide in an epoxy is essentially an organic compound very similar to ammonia, but has had one of its hydrogen atoms replaced with another atom. Single Source. Before permanent installation, test the equipment with the chemicals and under the specific conditions of your application. Advantages Excellent surface finish even when reinforced Strength Stiffness Chemical resistance to hydrocarbons Limitations High water absorption Poor chemical resistance to strong acids and bases OverviewBecause of nylons versatility, it is one of the most widely used engineering thermoplastics. Semi-Crystalline Characteristics. Polyamides (PA) can be modified with fillers, fibers, internal lubricants, impact modifiers etc. While this polyamide The first semi-transparent polyamide Chemical resistance Ultramid Vision shows excellent chemical resistance. .

The ratings for these materials are based upon the chemical resistance only. Vitamins and Minerals Medicines. In addition, nylon is easy to injection mold and extrude. They are produced both in solid form and as fibres. 1 Introduction . Fluid, Electrolyte, and Acid-base Balance. Coatings, adhesives, caulks and grouts. End users should conduct their own evaluation of RTP Company compounds to ensure satisfactory compatibility with any environmental or physical conditions PERMACOAT 3000, PERMATEC 3000, PERMACAST 3000. Polyamide resin has extremely amazing resistance against attack by aliphatic, aromatic hydrocarbons.

CPVC Corzan is a highquality and durable - compound of CPVC, which outlasts most other CPVC compounds. CHEMICAL RESIStANCE ViCTrEx PEEk Polymers. B = Slight attack by absorption.

Acrylic (PMMA) biocompatibility PMMA is very biocompatible with human tissue.

A polyamide epoxy is commonly used as a coating or an adhesive.

The easy to use Ancamide2832 & Ancamide 2864 curing agents not only provide faster turnaround, but they also provide exceptional asset protection, aesthetics, high corrosion and chemical resistance, and excellent blush resistance for a high The name "nylons" refers to the group of plastics known as polyamides.

Polyester, Acrylic, Polyamide & Aramyd. PEEK is a high-performance plastic that is incredibly resistant to harsh chemicals, fresh and saltwater, and steam. Coatings, adhesives, caulks and grouts. Nylon is generally chemically resistant to oils and fuels, gasoline, mineral spirits, and some alcohols Nylon has a high melting point, around 256C / 492F NOT compatible with ozone, most acids Nylon Chemical Compatibility Chart: Check the chemical compatibility of Nylon with various chemicals, solvents, alcohols and other products. PA46 is the polyamide exhibiting the highest temperature resistance. Many conditions can affect material chioices. The material selection platform Polyamide 6-6: Non Satisfactory PA 66 30% GF: Polyamide 6-6 30% glass fiber: Non Satisfactory PA 66 30% mineral filled: Polyamide 6-6 30% mineral filled: Thermosetting polymers are widely used as industrial materials due to good heat resistance, dimensional stability and chemical resistance. 2.1.1 Integrated 3D-printed reactionware for chemical synthesis and analysis; 2.1.2 Configurable 3D-Printed millifluidic and microfluidic 'lab on a chip' reactionware devices; 2.1.3 Continuous parallel ESI-MS analysis of reactions carried out in a bespoke 3D printed device; 2.1.4 Combining 3D printing and liquid handling to produce user Chemical Resistance Guide 4 Nylon (Polyamide) is one of the first thermoplastics used as rubber cords, belts, sports apparel, and structural parts such as valve bearings. A polyamide epoxy is a polymer that employs a polyamide resin as a curing agent.

Corotech V400 Polyamide Epoxy is a multi-use epoxy designed for coating items including tanks, machinery, floors, structural members, walls and other industrial and commercial substrates requiring a durable and resistant finish. Chemical resistance is based on testing at ambient temperatures in the specific chemical. Americhem utilizes the inherent properties in polymers to create customized blends that bring about a desired balance of properties, including the enhanced chemical resistance of plastics. For elevated temperature exposure contact ChemProof Polymers for a product recommendation. For example, they are more resistant to alkaline hydrolysis than polyesters but not as resistant to acid hydrolysis. We offer customized variations of Shakespeare PA612 products to suit specific processing needs and end use applications.

The main properties of wholly aromatic polyamides include thermal and. The two monomers are benzene-1,4-dicarboxylic acid and 1,4-diaminobenzene.

Acrylic (PMMA) biocompatibility PMMA is very biocompatible with human tissue. Chemical 73F 23C 212F 100C 392F 200C E t HERS Diethylether A A Dioxane A Ether A A Ethylene Oxide (EtO) A Tetrahydrofuran (THF) A HALOGENAtED ORGANICS 1,1,1 Trichloroethane (Genklene1) A 1,2 Dichloroethane A Carbon Tetrachloride A A

polyamide 6.6 (PA 66) is obtained by reaction of adipic acid with hexamethylenediamine. Power Adhesives Tec 7785 is a high temperature chemical resistant polyamide adhesive. Polyamide nanofibers have properties such as good chemical resistance, very good strength and hardness, high wear resistance, and high surface area to volume ratio, and they are porous, just to name a few. A = No Attack, possibly slight absorption.

Chemical resistance data from immersion tests cannot be unconditionally applied to thermoplastic piping components subjected to continuous or frequent mechanical or thermal stresses.

Chemical resistance data from immersion tests cannot be unconditionally applied to thermoplastic piping components subjected to continuous or frequent mechanical or thermal stresses. CPVC Because it is BPA free, it is also a useful BPA-free alternative to polycarbonate frequently used for making component parts for medical, biological and Polyamides exhibit high temperature and electrical resistance. Thanks to their crystalline structure, they also show excellent chemical resistance. They have very good mechanical and barrier properties. In addition, these materials can easily be flame retarded. Polyamides became the first truly synthetic fiber to be commercialized.

PA - Polyamide (PA 6, PA 6.6, PA 11, PA 12) Polyamides are long chain polymers containing amide units (N-H- C=O). Material will have limited life. Not resistant to ozone, hydrochloric acid, sulphuric acid and hydrogen peroxide. possible to get an idea of the chemical resistance based on the type of chemical product.

Advertisement. It has a high chemical resistance compared with traditional polymers. PEEK also emits low smoke and toxic fumes when exposed to flame, increasing its high-temperature applications.

Based on this success, and leveraging GENESTAR 's unique characteristics, Kuraray now seeks to It offers high impact strength, high dimensional properties such as high chemical resistance, wide application temperature range, good UV resistance (i.e. Polyamide-imide (PAI) resins are thermoset ultra-polymers that are robust, chemical resistant and thermally stable. Polyimides are generally thermosetting polymers; however, thermoplastic polyimides can be obtained by introducing large cyclic side groups to the polymer chain [2]. MOMENTIVE. MOMENTIVE. Properties of Unfilled and Reinforced Polyamide-imides (PAI) 8.4.3 PAIs Chemical Resistance and Sterilization PAIs are resistant to most dilute acids and bases and most organic solvents ( Table 8.2 ). VALLADYN PA612 offers excellent melt stability, barrier properties, dimensional stability, low moisture absorption, and chemical resistance. Ultimately, the consumer must determine the chemical compatibility of an item based on the conditions in which the product is being used. chemical stability and the potential for high strength and modulus. They have outstanding thermal, mechanical, and chemical properties and are often the best choice for demanding applications where very high mechanical strength, stiffness and low friction in combination with high temperature, The global polyamide market size was valued at USD 33.30 billion in 2020 and is expected to expand at a compound annual growth rate (CAGR) of 6.2% from 2021 to 2028. There is a longstanding and widespread interest in designing novel polymer networks, and utilization of ionic liquids (ILs) opens up new frontiers to meet this challenge by creating new materials. With the chemical properties of plastic varying significantly, chemical resistance is influenced by the polymer used for a particular application and the chemicals used within that application.

Thermosetting polymers are widely used as industrial materials due to good heat resistance, dimensional stability and chemical resistance.

Concen- tration % at temp. If the chemistry of polymer molecules were different from that of simple compounds resembling the repeating units (model compounds), the study of the chemical resistance of organic polymers would be difficult.

Nylon 6,6; Nylon 6,12; Nylon 4,6; Nylon 6; Nylon 12 etc. Polyamide-imides are either thermosetting or thermoplastic, amorphous polymers that have exceptional mechanical, thermal and chemical resistant properties. Chemical Resistance. B = Good -- Minor Effect, slight corrosion or discoloration. chemical resistance. Nylon is probably the costliest of the ordinary thermoplastics. VIP-Polymers Ltd. 15 Windover Road, Huntingdon, PE29 7EB, UK Tel: +44 (0) 1480 411333 Fax: +44 (0) 1480 413991 Email: [emailprotected]polymers.com www.vip-polymers.com Chemical Compatibility Guide A=Excellent, B=Good, C=Fair, X=Not Recommended, Blank=Insufficient Information 1 Isse 2.0 Chemical SBR EPDM NBR FKM FFKM Acetaldehyde - B X X A Polyamides are among the most important and useful technical thermoplastics due to their outstanding wear resistance, good coefficient of friction, and very good temperature and impact properties. of the polymer, suitable for coupling. PEEK maintains stiffness at high temperatures and is suitable for continuous use up to 170C (338F). This process is a bit different from a chemical attack since it doesn't affect the molecular structure of the polymers. Rating Scale: 1= Little or no impact 2= Minor effect 3= Moderate effect 4= Severe effect

Both are tough and have resistance to abrasion. Tabla 2. [www.corzancpvc.com] Available for the majority of our product lines.

Both are tough and have resistance to abrasion. Tabla 2. [www.corzancpvc.com] Available for the majority of our product lines. Advertisement.

A polyamide epoxy is a polymer that employs a polyamide resin as a curing agent. View Freelin-Wade's chemical resistant plastic tubing options available now! SABICs polymers portfolio is organized largely around the automotive, foam/lightweight and pipe segments, helping find the right alternatives to replace traditional materials wood, cotton or glass used in a vast array of consumer and industrial products. PERMACOAT 5000, PERMATEC 5000, PERMACAST 5000.

Having marked present according to the most . Description. High viscosity polyamide at 70% weight solids in xylene, offers long pot life. 1 Introduction; 2 Sources.

resistance typical of fluorocarbon polymers.

resistance typical of fluorocarbon polymers. Generic Description Polyamide Epoxy; Its enhanced chemical resistance and physical properties make it an excellent, cost-effective choice for corrosion control in tanks handling brine water, drilling mud, mild temperature backflow, and a wide range of chemicals used in the oil and gas industry. Negligible effect on mechanical properties. These chemical and environmental resistance ratings for thermoplastics are provided for comparison purposes only. Inadequate chemical resistance will reveal itself through material cracking, swelling, softening, discoloration and shortened service life.

Among the many polyamide types, nylon 6 and nylon 6/6 are the cheapest. Naval specification Mil-P-24441A(SH) RECOMMENDED: HIGHLY RECOMMENDED: (1) Other applications include adhesives, electrical castings, electrical laminates and fibers Like PEIs, PAIs are capable of steam sterilization for up to 100 cycles.

Nylon is used in the production of film and fibre, but is also available as a moulding compound.

Corrosion of metals results in a gradual loss of surface material as a result of electrolytic action by the relevant chemicals.

Synthetic Anti-infective Drugs. High viscosity polyamide at 70% weight solids in xylene, offers long pot life. Added consideration must be given to pump selections when the chemical is abrasive, viscous in nature, or has a Specific Gravity greater than 1.1. Get detailed information about chemical resistance of various plastics to hydrogen peroxide @ 30%, 60C with its other important information. l Moderate chemical resistance l: High impact strength Typically used for safety shields: SciLabware Limited, Unit 4, Riverside 2, Campbell Road, Stoke-on-Trent, Staffordshire, ST4 4RJ, wUK +44 (0) 1782 444406: This technical information is provided in Chemical Resistance or Substance Opposition: Cast polyamides provide superior protection against synthetics as compared to wires and connections in severe environments. Aptalon M8100 Polyamide Polyurethane is designed to deliver very high performance topcoats for paint and coating applications. Chemical Compatibility Plastic Material Chart for PA66, PEEK, PPS, 3-(2-Aminoethylane ) -3Aminopropyl trimethoxysilane. Synthetic Anti-infective Drugs.

With high heat resistance, this plastic resin is suitable for high-temperature applications. Leading Provider. PAI (Polyamide-imide) PAI is another high-performance thermoplastic with high-temperature resistance, high thermal stability, good chemical resistance, and supreme wear properties with temperatures up to 275C. EPIKURE 3125A. Good to excellent resistance to greases, oils, fuels, hydraulic fluids, and many solvents as well as to salt solutions and other chemicals. The name "nylons" refers to the group of plastics known as polyamides. Medium viscosity polyamide, provides non- critical combining ratios, toughness, flexibility, corrosion- and water- resistance. However, it does seriously affect the physical structure of the plastic part. Adhesives / Sealants: Epoxy Polyamide cured systems impart good wetting of the substrates giving good adhesion, water and chemical resistance. PVC Polyvinyl Chloride - Chemical Resistance - Chemical resistance of Polyvinyl Chloride PVC. Other factors influencing chemical resistance include the reagent, reagent concentration, temperature, exposure time and whether the polymer is under stress. Polyamide 12 is a polymer from an extremely versatile petrochemical origin, with features that can vary from rigid, with Elastic Moduli of around 1400MPa, to super flexible with Elastic Moduli of around 250MPa.In addition, its affinity with olefinic rubbers allows it to have optimal resistance to low temperatures. Polyimide Physical Properties - Chemical Resistance ot Days 365 23cc 365 @ 230C 365 @ 230 365 @ wc 5 @ % ot Tensile % ot Elongation Resistance To: Benzene Toluene Methanol Aceton e Sodium Hydroxide Transformer Oil Water pH = I pH 10 Degrades Degrades 180 @ 150'C 150ac 1 oooc 230 14 166 @ Polyester, Acrylic, Polyamide & Aramyd

It features a low surface tension, second lowest compared to fluorine polymers, giving it excellent release-ability against various materials.

Medium viscosity polyamide, provides non- critical combining ratios, toughness, flexibility, corrosion- and water- resistance. Polyamides are prone to oxidation and yellowing in sunlight. Reagens PA 6 PA 6 PA 12 PU PP PVC SI* TPE NBR. Other Chemical Drugs. Acetaldehyde, hydrous 40 20 o o + + - o 20C o Acetic acid 10 20 o o o - + + o + - Acetic acid pure 100 20 o o Polypropylene, Polyvinyl, Politetrafluoro-Etilenica, Glass & Cotton. Explore chemical resistance & polymer properties of many engineering plastics. cyclohexane), fats and oils, and to solvents of medium polarity (methyl ethyl ketone) and high polarity (isopropanol).

COMPANY WITH QUALITY SYSTEM CERTIFIED BY DNV GL = UNI EN ISO 9001:2015 = It absorbs little water and as a result its mechanical properties and high dimensional stability change little when exposed to fluctuating environmental humidity. CPVC Corzan is a highquality and durable - compound of CPVC, which outlasts most other CPVC compounds. 1994. It possesses moderate resistance to most of the halogenated hydrocarbons. [www.corzancpvc.com] Available for the majority of our product lines. Based on its structure you can classify the reagent into one of the chemical groups figuring in Table II on page 25: aldehydes, ketones, inorganic acids Of course, to do so, some chemistry knowledge is required. The data below shows PVDF chemical resistance results for both our homopolymer and copolymer 3D printing filaments. This information is intended is intended as a guide only. There are several types of coatings pipe such as fiberglass, polymers and elastomers, but the fluoropolymers In certain environments, the chemical resistance of standard epoxies and urethanes just won't cut it. Polyamide Polyamide Polyamide Thermoplastic Polypropylene % +C Polyurethane Reagent PA 6 PA 66 PA 12 PU PP Ethylene oxide, liquid 100 20 o Ferric cyanide, hydrous saturated 60 + Ferrous chloride, hydrous, indiff. Kevlar is similar in structure to nylon-6,6 except that instead of the amide links joining chains of carbon atoms together, they join benzene rings. The polymer, however, may be attacked by saturated steam, strong bases, and some high-temperature acid systems. Nervous System Drugs. Broad chemical resistance includes strong acids and most organics. Polyamides have several advantages over other classes of engineering polymers. Table 1. Chemical Properties. of Industrial Flooring. Longer durability Unique mechanical properties at various temperatures and low permeability make Technyl grades the materials of choice for applications where long service life is a vital factor.

Ensinger Special Polymers, Inc. 12331 Cutten Road, Houston, TX 77066 Tel: 281-580-3600 Chemically resistant to many acids, oxidizing / reducing agents, neutral and acid salt solutions, greases, oils, detergents, saturated, aliphatic and cycloaliphatic hydrocarbons and alcohols. Digestive System Drugs. PA1010 is semicrystalline, which is the reason for its high mechanical resistance and chemical stability.

Excellent wear resistance When blended with internal lubricants, offers excellent tribological properties.

Fluid, Electrolyte, and Acid-base Balance.

Polyamideimides (PAIs) are high performance amorphous engineering thermoplastics of yellow to brown color. A polyamide in an epoxy is essentially an organic compound very similar to ammonia, but has had one of its hydrogen atoms replaced with another atom. Single Source. Before permanent installation, test the equipment with the chemicals and under the specific conditions of your application. Advantages Excellent surface finish even when reinforced Strength Stiffness Chemical resistance to hydrocarbons Limitations High water absorption Poor chemical resistance to strong acids and bases OverviewBecause of nylons versatility, it is one of the most widely used engineering thermoplastics. Semi-Crystalline Characteristics. Polyamides (PA) can be modified with fillers, fibers, internal lubricants, impact modifiers etc. While this polyamide The first semi-transparent polyamide Chemical resistance Ultramid Vision shows excellent chemical resistance. .

The ratings for these materials are based upon the chemical resistance only. Vitamins and Minerals Medicines. In addition, nylon is easy to injection mold and extrude. They are produced both in solid form and as fibres. 1 Introduction . Fluid, Electrolyte, and Acid-base Balance. Coatings, adhesives, caulks and grouts. End users should conduct their own evaluation of RTP Company compounds to ensure satisfactory compatibility with any environmental or physical conditions PERMACOAT 3000, PERMATEC 3000, PERMACAST 3000. Polyamide resin has extremely amazing resistance against attack by aliphatic, aromatic hydrocarbons.

CPVC Corzan is a highquality and durable - compound of CPVC, which outlasts most other CPVC compounds. CHEMICAL RESIStANCE ViCTrEx PEEk Polymers. B = Slight attack by absorption.

Acrylic (PMMA) biocompatibility PMMA is very biocompatible with human tissue.

A polyamide epoxy is commonly used as a coating or an adhesive.

The easy to use Ancamide2832 & Ancamide 2864 curing agents not only provide faster turnaround, but they also provide exceptional asset protection, aesthetics, high corrosion and chemical resistance, and excellent blush resistance for a high The name "nylons" refers to the group of plastics known as polyamides.

Polyester, Acrylic, Polyamide & Aramyd. PEEK is a high-performance plastic that is incredibly resistant to harsh chemicals, fresh and saltwater, and steam. Coatings, adhesives, caulks and grouts. Nylon is generally chemically resistant to oils and fuels, gasoline, mineral spirits, and some alcohols Nylon has a high melting point, around 256C / 492F NOT compatible with ozone, most acids Nylon Chemical Compatibility Chart: Check the chemical compatibility of Nylon with various chemicals, solvents, alcohols and other products. PA46 is the polyamide exhibiting the highest temperature resistance. Many conditions can affect material chioices. The material selection platform Polyamide 6-6: Non Satisfactory PA 66 30% GF: Polyamide 6-6 30% glass fiber: Non Satisfactory PA 66 30% mineral filled: Polyamide 6-6 30% mineral filled: Thermosetting polymers are widely used as industrial materials due to good heat resistance, dimensional stability and chemical resistance. 2.1.1 Integrated 3D-printed reactionware for chemical synthesis and analysis; 2.1.2 Configurable 3D-Printed millifluidic and microfluidic 'lab on a chip' reactionware devices; 2.1.3 Continuous parallel ESI-MS analysis of reactions carried out in a bespoke 3D printed device; 2.1.4 Combining 3D printing and liquid handling to produce user Chemical Resistance Guide 4 Nylon (Polyamide) is one of the first thermoplastics used as rubber cords, belts, sports apparel, and structural parts such as valve bearings. A polyamide epoxy is a polymer that employs a polyamide resin as a curing agent.

Corotech V400 Polyamide Epoxy is a multi-use epoxy designed for coating items including tanks, machinery, floors, structural members, walls and other industrial and commercial substrates requiring a durable and resistant finish. Chemical resistance is based on testing at ambient temperatures in the specific chemical. Americhem utilizes the inherent properties in polymers to create customized blends that bring about a desired balance of properties, including the enhanced chemical resistance of plastics. For elevated temperature exposure contact ChemProof Polymers for a product recommendation. For example, they are more resistant to alkaline hydrolysis than polyesters but not as resistant to acid hydrolysis. We offer customized variations of Shakespeare PA612 products to suit specific processing needs and end use applications.

The main properties of wholly aromatic polyamides include thermal and. The two monomers are benzene-1,4-dicarboxylic acid and 1,4-diaminobenzene.

Acrylic (PMMA) biocompatibility PMMA is very biocompatible with human tissue. Chemical 73F 23C 212F 100C 392F 200C E t HERS Diethylether A A Dioxane A Ether A A Ethylene Oxide (EtO) A Tetrahydrofuran (THF) A HALOGENAtED ORGANICS 1,1,1 Trichloroethane (Genklene1) A 1,2 Dichloroethane A Carbon Tetrachloride A A