Identify risks and opportunities and proactively drive improvement initiatives, Bachelors Degree or equivalent in engineering related field preferred, Demonstrated project management expertise, Minimum of 5 years of experience in quoting and estimating experience in the Injection Molding and Plastics space, Minimum of 2 years of experience in a team lead or management experience, Proficiency in reading mechanical drawings and understanding GD&T. Welcome to the latest edition of our 3D printing jobs and career moves update for the additive manufacturing sector.

Molds for injection molding are normally CNC machined out of aluminum or tool steel, EDM machined to shape a workpiece, or 3D printed. You can also stay connected by following us onTwitterand liking us onFacebook.

plastic injection molding rib mold sink moulding mechanical ribs guide guidelines parts ratio warp boss 3d engineering hinge living plastics Monitoring costs: Despite the reliance on automation, equipment operators are expected to monitor the progress of the injection molding process.

injection molding problems steps fix chart try plastics conversation

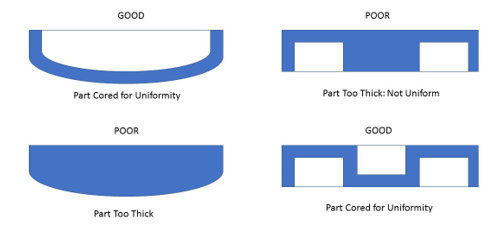

This reduces the molds size and the material used to develop the model. You might have a standard list of materials that you keep in stock and you don't really strive outside of that list.

Special-purpose machines are used for injection molding that can range from smaller desktop injection molding machines that businesses can use in-house to large industrial injection molding machines that are mostly operated by service providers, contract manufacturers, and large manufacturers. In a release the company said acquiring Thomas will expand its buyer and seller base, and give it the chance to leverage Thomass marketing and data services, which are utilized by manufacturers to help drive business.

Lafayette-based manufacturer NOA Brands America is seeking a 3D Printing and Scanning Technician to be responsible for operating its in-house 3D printers and 3D scanners. One of the important process parameters to establish and record for any injection molded part is its injection or fill time. In this white paper, learn how to combine rapid tooling with traditional manufacturing processes like injection molding, thermoforming, or casting. California Do Not Track Notice. Low volume projects might require 3D printed or lower-grade machined aluminum molds, while large production volumes will require high-grade steel molds or even multiple molds to manage the process without wear and tear affecting the quality of produced items.

The technical sales engineer at Xometry, the worlds largest digital manufacturing marketplace, goes on to explains that injection molding parts can be found in anything that you can see around your house, from consumables, and medical, to aerospace and defense. (See more injection molded products here.). Production grades are usually Class 102-104, with Class 101 used for an extremely high production mold and Class 105 for a simple prototype. Global manufacturing marketplace Xometry has appointed former PayPal executive Ranjana Clark to its Board of Directors. The platform hosts 2 million sourcing sessions/month.

The technical sales engineer at Xometry, the worlds largest digital manufacturing marketplace, goes on to explains that injection molding parts can be found in anything that you can see around your house, from consumables, and medical, to aerospace and defense. (See more injection molded products here.). Production grades are usually Class 102-104, with Class 101 used for an extremely high production mold and Class 105 for a simple prototype. Global manufacturing marketplace Xometry has appointed former PayPal executive Ranjana Clark to its Board of Directors. The platform hosts 2 million sourcing sessions/month.

Operator wages accrued during the process are added to the total cost of injection molding. Setup/configuration cost: The setup labor focuses on the time taken to configure the utilized equipment to produce the mold and the finished product. As we mentioned in the introduction, mold costs or tooling costs are usually the main cost driver in injection molding. Sign up here to get the days top stories delivered straight to your inbox. Hayley is a Technology Journalist for 3DPI and has a background in B2B publications spanning manufacturing, tools and cycling. Privacy Statement and

Writing news and features, she holds a keen interest in emerging technologies which are impacting the world we live in. Find and evaluate OEMs, Custom Manufacturers, Service Companies and Distributors. injection Copyright 2017 | All Rights Reserved | 3D Printing Industry, New 3D printing jobs at NOA Brands America, appointments at Xometry, 9T Labs and more, Evatronix launches eviXscan Quadro+ 3D scanner technical specifications and pricing, Revopoint launches the MINI 3D scanner on Kickstarter technical specifications and pricing, Shining 3D launches its FreeScan UE Pro 3D scanner technical specifications and pricing, Thales Alenia Space and MIPRONS to develop innovative water-powered satellite thruster, Students 3D print unique 23-foot-high learning lab that fits inside SpaceXs Starship rocket, 3D Systems and Fleet Space partner to 3D print patch antennas for satellites, BMF to accelerate microprinting expansion after raising another $43M, Prodways raises guidance after seeing record-breaking sales in H1 2022, Stratasys comments on poison pill filing after Nano Dimension purchase fuels takeover speculation, SME and Wi3DP team up to advance workforce diversity in 3D printing, Powder Handling and Flow for Additive Manufacturing: Short course, Somerset Community College to provide 3D printing technology training for those in need, CONTEXT reports reversal of pandemic 3D printing trends amid robust full-year growth projections, Powering the renewable energy transition with 3D printing: Component optimization, Powering the renewable energy transition with 3D printing: Decarbonization, Dentists develop unique 2-in-1 3D printed toothbrush handle for people with dexterity impairments, Triastek and Eli Lilly partner to 3D print gastrointestinal drugs, 3D printed cornea transplants at Precise Bio gain new R&D funding from Carl Zeiss Meditec, Alstom and Replique aim for rolling stock series production with 3D printing technology, Eplus3D unveils brake discs produced using 3D printing technology, Alstom slashes spare part lead times by 95% using Stratasys 3D printing technology, how to get a job in the 3D printing industry, New 3D printing jobs at Penn State, polySpectra and MetShape, appointments at XJet, Markforged and more, New 3D printing jobs at Cartier, appointments at Azul 3D, Desktop Metal, Wi3DP and more, New 3D printing jobs, hires and facilities at Kymera International, Desktop Metal, Launcher, 3YOURMIND and more, New 3D printing jobs at Rapid Liquid Print, hires at MxD, GE, Sculpteo, and facilities at Huawei and Renishaw, New 3D printing jobs, hires at AMGTA, Autodesk, Carbon, facilities at Collins and more, New 3D printing jobs at Hephaestus Labs, hires at XJet, Carbon, facilities at Artec 3D and more, New 3D printing jobs, appointments and facilities at DigiFabster, 3D Systems, XJet, Roboze, ICON, EOS and more, New 3D printing jobs at Headmade Materials, Eaton, NanoAL, hires at Sigma Labs, Xaar, Renishaw, facilities at GE Aviation, CAES and more, New 3D printing jobs at HP, hires at 9T Labs and AddUp, and facilities at Linde, ITDI and more, New 3D printing jobs, hires at Made Smarter, and facility news from ABB, Additive Engineering, SABIC and more, New 3D printing jobs, hires, and facility news from Fleet Space, Thales, Slant 3D and more, New 3D printing jobs at Eaton Aerospace and Y-12, appointments at UpNano, MxD, Carbon, Velo3D and more. The company has expanded its executive team with the appointment of Fabian Pusch to the role of Chief Technology Officer (CTO) and strengthened its commercial team with the hire of Arne Bttner as Sales Manager for the DACH region. The discharges are responsible for shaping the workpiece electrode into the final mold. Diving a little bit deeper into that, if you're limited to just what you have under one roof, you might not be able to do complex side actions or geometries like we do. The machined or printed part is then finished to achieve the desired standard. Even if you're prototyping in nylon, and then you want an injection molded nylon, that material isn't going to be the exact same. has acquired Thomas for $300 million, pairing two online marketplaces and directories of advanced manufacturing, with a goal of monetizing the buying and selling of services like injection molding, 3D printing, CNC machining and more. The biggest one is our ability to operate off of a partner network. This affects the cost of the mold, but of course, the increased cost of high volume molds is distributed among more parts, which normally leads to a lower per part cost.

While injection molding is traditionally considered a manufacturing process only for mass production due to its high tooling costs, leveraging 3D printing to fabricate injection molds empower you to use this process to produce high-quality and repeatable parts for prototyping and low-volume production. Website Last Modified July 29, 2022. 3D printed molds can produce 100+ parts affordably and within a few days. This role will lead, manage, support, mentor and grow the injection molding manual quoting team here at Xometry.

Electrical discharge machining (EDM): The EDM method is generally used to create highly complex mold designs that cannot be easily reproduced using standard machining methods. The same thing goes for any type of specific testing that needs to be done. injection moulding machine plastic molding mold rapid sketch coupler dust cap dc type ideal guide core material polypropylene flow Thus, cooling channels play an important role, especially for high-volume production, and should be included in the design of the mold.  2022 Gardner Business Media, Inc. Privacy Policy

2022 Gardner Business Media, Inc. Privacy Policy

Xometry is looking to hire a Quoting Manager, Molding department. The most popular materials are various thermoplastics, such as ABS, PS, PE, PC, PP, or TPU, but metals and ceramics can be injection molded as well.

Thomas uses cookies to ensure that we give you the best experience on our website.

troubleshooting Photo Credit: Getty.  injection plastic guide molding For molds with more complex geometries and primed for larger production runs of approximately 10,000+ units, the cost of mold can range from $5,000 to $100,000. Essentially, you start with nothing and end up with a part after the process is complete. They come to us saying, I got this feedback somewhere else that they couldn't make these. Connect and transact with thousands of top North American companies today This means that the variable costs of production are low and the process becomes more efficient and the cost per part decreases at higher volumes as the costs get distributed among hundreds or thousands of parts. Our objective is to produce the part as close to the initial design intent of the customer. It's not suited for really thick parts.

injection plastic guide molding For molds with more complex geometries and primed for larger production runs of approximately 10,000+ units, the cost of mold can range from $5,000 to $100,000. Essentially, you start with nothing and end up with a part after the process is complete. They come to us saying, I got this feedback somewhere else that they couldn't make these. Connect and transact with thousands of top North American companies today This means that the variable costs of production are low and the process becomes more efficient and the cost per part decreases at higher volumes as the costs get distributed among hundreds or thousands of parts. Our objective is to produce the part as close to the initial design intent of the customer. It's not suited for really thick parts.

Meanwhile, Swiss carbon fiber 3D printing specialist 9T Labs has announced a spate of new hires ahead of the launch of its hybrid 3D printing technology. The reason you dry certain plastics is to get the moisture out. Xometry is an equal opportunity employer.  For sellers, Xometry will offer access to buyers and a growing basket of seller services to help manufacturers more efficiently run their businesses..

For sellers, Xometry will offer access to buyers and a growing basket of seller services to help manufacturers more efficiently run their businesses..

But why does the moisture have to be taken out before processing? Other variables that impact the injection molding process and directly relate to the injection mold costs include: Part size: The larger the item or part to be molded, the larger its mold will be to accommodate the part. The $300 million purchase price included $198.5 million in cash and $101.5 in common stock. Xometry participates in E-Verify and after a job offer is accepted, will provide the federal government with your Form I-9 information to confirm that you are authorized to work in the U.S. Xometry (NASDAQ: XMTR) powers the industries of today and tomorrow by connecting the people with big ideas to the manufacturers who can bring them to life. The global company, headquartered in Gaithersburg, Maryland, provides 24-hour responses on quotes with design-for-manufacturing (DFM) feedback. Thomas Register and Furthermore, product development benefits from the ability to iterate on the design and test the end-use material before investing in hard tooling for mass production. The cost of purchasing materials for molds differs according to the material chosen.

Molds with complex Side A and Side B designs are generally more expensive to fabricate compared to simpler molds. However, as these costs get distributed among hundreds or thousands of parts, injection molding is an ideal process to mass-produce plastic parts affordably. The 3D Printing Industry jobs board is also free to use for employers to find 3D printing experts for their businesses. Injection molding is one of the leading processes for manufacturing plastics.

A degree in industrial design, engineering, 3D design or similar is also required, as is two or more years of work experience with 3D printers. We want to strive to be able to not provide any no quotes. Image Credit: Draftangle / Shutterstock.com, Additive Manufacturing / 3D Manufacturing, Select From Over 500,000 Industrial Suppliers. When a business outsources injection molding, the labor and the markup of the service provider are added to the service cost. Bttner, meanwhile, has spent seven years as a Sales Manager at AFPT, and Borlenghi has held prior roles at Roboze and 3devo.

Equipped with more than 30 years of executive experience in the financial services industry, Clark was named as one of the American Bankers Most Powerful Women in Banking in 2020. Subscribe to the3D Printing Industry newsletterfor the latest news in additive manufacturing.  In this webinar, we'll show you how to use stereolithography (SLA) 3D printed molds in the injection molding process to lower costs, reduce lead times, and bring better products to market. Xaars new facility houses the companys finance, HR, legal and marketing divisions, alongside a new purpose-built R&D laboratory.

In this webinar, we'll show you how to use stereolithography (SLA) 3D printed molds in the injection molding process to lower costs, reduce lead times, and bring better products to market. Xaars new facility houses the companys finance, HR, legal and marketing divisions, alongside a new purpose-built R&D laboratory.  Mold designs usually have 2 sides: sides A and B.

Mold designs usually have 2 sides: sides A and B.

Subscribe to ourYouTube channelfor the latest 3D printing video shorts, reviews and webinar replays. The core cavity approach involves sinking the wall cavities into the mold base, thereby reducing the need to mold steep draft angles while improving surface finish.

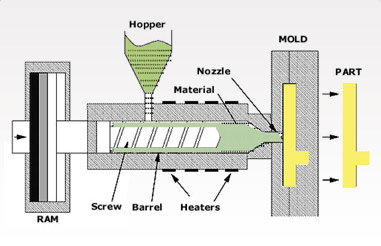

The equipment associated with injection molding is generally self-regulating and relies on automation to get the job done. Over the past decade, soft-touch overmolding has radically changed the look, feel, and function of a broad range of consumer products.  It is a fast, intensive process where high heat and pressure are involved to inject molten material inside a mold. Typically, anywhere you see injection molded parts they had to start somewhere with another process like a prototyping process such as CNC machining or 3D printing. In general, injection molding is the most efficient at higher volumes, as the costs then get distributed among thousands of parts.

It is a fast, intensive process where high heat and pressure are involved to inject molten material inside a mold. Typically, anywhere you see injection molded parts they had to start somewhere with another process like a prototyping process such as CNC machining or 3D printing. In general, injection molding is the most efficient at higher volumes, as the costs then get distributed among thousands of parts.

We have expanded our team and are happy to announce that Fabian Pusch, a molding expert with a strong business background, joins our executive team as CTO, said Martin Eichenhofer, 9T Labs CEO and Co-founder. The headquarters also provides a significantly reduced carbon footprint for the firm. [Log On], Robert Bosch Venture Capital Invests in Xometry's Manufacturing Marketplace, Stratasys Direct, Xometry Team to Deliver High-Performance 3D Printed Parts on Demand, Xometry Adds Carbon to Its Network Platform, Injection Molding: You Must Dry Hygroscopic Resins, How to Optimize Adhesion in Hard-Soft Overmolding, A New Look at Evaluating Fill Times For Injection Molding. Material cost is defined by a models design, the material chosen, and the amount of material used to execute the injection molding process. Welcome to Thomas Insights every day, we publish the latest news and analysis to keep our readers up to date on whats happening in industry. She will leverage the experience gained in her previous global marketing, strategy, and business leadership roles to accelerate Xometrys growth and advance its set of financial products and services to help its sellers manage cash flow at all stages of job production. In addition to possessing a high mechanical aptitude, the ideal candidate will have an in-depth knowledge of 3D printing and design processes and a working knowledge of CAD and 3D scanning.

Founded in 2013, Xometry expanded into Europe in 2019. Read on for the latest career moves, facility openings, and job opportunities from Xometry, NOA Brands America, 9T Labs, Xaar, and more. Injection molding does have a lot of design requirements that go into designing for this process.  CNC machining and 3D printing are both very commonly used processes to prototype for the injection molding process, which plays a much bigger role in the production environment when making plastic parts. The move builds on Xaars recent rebrand and launch of its ImagineX platform as it looks to advance the development of inkjet technology for 3D printing and manufacturing. KS: There are a few factors that go into choosing injection molding. Additionally, this role will be to serve as a working manager, essentially performing the standard work related to quoting and estimating activities, with a focus on high value, complex and strategically important initiatives, Daily, ensure quote queue is allocated to the various team members, Support team members through prioritization, technical discussions, quote strategies, Submit quotes to sales for review and customer presentations, Support technical presentations as required, Engage with manufacturing partners to confirm quote strategy and specific terms, Obtain/Prepare basic DFM feedback, along with general optimization ideas. Team-leading ability to motivate and influence others to support cost estimating, meet deadlines, and provide assumptions.

CNC machining and 3D printing are both very commonly used processes to prototype for the injection molding process, which plays a much bigger role in the production environment when making plastic parts. The move builds on Xaars recent rebrand and launch of its ImagineX platform as it looks to advance the development of inkjet technology for 3D printing and manufacturing. KS: There are a few factors that go into choosing injection molding. Additionally, this role will be to serve as a working manager, essentially performing the standard work related to quoting and estimating activities, with a focus on high value, complex and strategically important initiatives, Daily, ensure quote queue is allocated to the various team members, Support team members through prioritization, technical discussions, quote strategies, Submit quotes to sales for review and customer presentations, Support technical presentations as required, Engage with manufacturing partners to confirm quote strategy and specific terms, Obtain/Prepare basic DFM feedback, along with general optimization ideas. Team-leading ability to motivate and influence others to support cost estimating, meet deadlines, and provide assumptions.

We advise adhering to design for manufacturing principles to drive down part costs with injection molding. Part design: Complex part designs with intricate geometries require complex molds to execute the project.  3D printing: 3D printing is a powerful solution to fabricate injection molds rapidly and at a low cost. CNC machines, EDM machines, and 3D printers rely on the specifications of the CAD design to produce a mold. molding injection xometry service capabilities

3D printing: 3D printing is a powerful solution to fabricate injection molds rapidly and at a low cost. CNC machines, EDM machines, and 3D printers rely on the specifications of the CAD design to produce a mold. molding injection xometry service capabilities

Online injection molding cost estimators or quotes from injection molding service providers can provide benchmarks and help you estimate the cost of injection molding specific parts. Increased press time slows down the production process which leads to increased cost. Giovanni Cavolina, 9T Labs CCO and fellow Co-founder, added: We also have expanded our sales territory and welcome both Arne Bttner, who will be managing DACH and brings strong expertise in automated, high-performance composites manufacturing, and Andrea Borlenghi who will manage Italy and has solid experience in 3D printing high-performance thermoplastic materials.. How Deep Under the Ocean Have Humans Explored?

Tooling costs for injection molding are very high and depend on a number of parameters and design complexity. But even though the cost per part for low-volume injection molding is slightly higher, it is still substantially more affordable for low-volume production than other manufacturing methods. Featured image shows the 3D Printing Industry Jobs Board. EDM involves the use of a workpiece and a tool electrode to create the desired mold shape.

Large industrial injection molding machines can cost anywhere from $50,000 to $200,000+.  We have dozens of similar job posts on our site, interested? guidelines moulding injection stepping conventional beyond spra followed started he Larger mold designs usually come at an increased cost compared to fabricating the same design but with smaller dimensions. Clark is the Head of Global Transaction Banking, Head of Transaction Banking Americas, and Bay Area President of Mitsubishi UFJ Financial Group (MUFG), and will provide counsel to Xometry on its payments and business strategies. Thomasnet Is A Registered Trademark Of Thomas Publishing Xometry provides a digital marketplace with real-time access to manufacturing capacity and demand. Side A, also known as the cosmetic side, is usually the side seen by the user. medical There are injection molding parts everywhere, says Kyra Stawson. Fabians experience with plastics machinery as well as computer-aided engineering will be very helpful as we work to round out our team..

We have dozens of similar job posts on our site, interested? guidelines moulding injection stepping conventional beyond spra followed started he Larger mold designs usually come at an increased cost compared to fabricating the same design but with smaller dimensions. Clark is the Head of Global Transaction Banking, Head of Transaction Banking Americas, and Bay Area President of Mitsubishi UFJ Financial Group (MUFG), and will provide counsel to Xometry on its payments and business strategies. Thomasnet Is A Registered Trademark Of Thomas Publishing Xometry provides a digital marketplace with real-time access to manufacturing capacity and demand. Side A, also known as the cosmetic side, is usually the side seen by the user. medical There are injection molding parts everywhere, says Kyra Stawson. Fabians experience with plastics machinery as well as computer-aided engineering will be very helpful as we work to round out our team..

If you're doing impact testing or tensile testing, you want to make sure that you're actually using an injection molded part because the difference in properties going from injection molding parts to 3D printed parts, for example, is going to be much different.

vdi xometry Part volume and cavities: Part volume refers to the cavity size of a mold. If the tools needed for injection molding are not readily available, then outsourcing reduces the cost associated with developing a mold. A lot of our competition is limited to what capabilities they have under one roof, while we can go out and talk amongst our 5,000-plus partners, who could do something when maybe other molders can't. Similar to CNC machining, EDM is also an industrial process that many companies outsource to machine shops. When calculating for the shrink rate, theres a further +/- 0.002. That said, for critical features, Xometry can machine to a steel-safe condition if an even tighter tolerance is needed. Evaluate the models design to eliminate unnecessary features. As a result, enterprises often outsource specific aspects of the injection molding process such as the design and fabrication of the mold. These machines also come with more stringent facility requirements and require skilled labor for operation, maintenance, and monitoring. The digital marketplace for on-demand manufacturing acquired the product sourcing, supplier selection and digital marketing provider for $300 million. molding handbook injection It is a cost-effective and extremely repeatable technology that yields high-quality parts for large series production. core mold mechanism lateral oblique injection parting pulling column slider guide die angle Developing more complex molds requires technical expertise.

Despite the considerable fixed start-up costs, the injection molding process has low variable costs due to the inexpensive thermoplastics materials, short cycle times, and the labor needs decrease progressively due to automation and economies of scale.