Make a PLC Ladder diagram for Automatic car washing process using PLC program in RSLOGIX 500 software.

Copyright 2022 Nevon Projects | All Rights Reserved. It may vary from real time. Be the first to get exclusive content straight to your email. The system has a IR sensor to check if a car has been parked in the system.

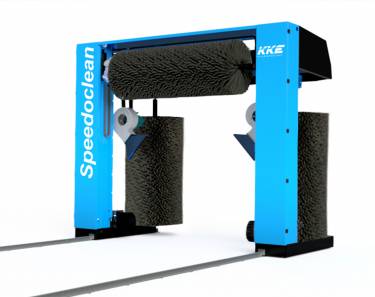

Copyright 2022 Nevon Projects | All Rights Reserved. It may vary from real time. Be the first to get exclusive content straight to your email. The system has a IR sensor to check if a car has been parked in the system.  2011-2022 Sanfoundry. The system consists of a small conveyor type belt that holds on to a car. Car entry sensor triggers the process and turns conveyor belt ON to move the car. ON/OFF operation of conveyor motor is happening in this rung using various conditions like Sensor input and timer done output. This stage has a preliminary sprayer that sprays water on the car and passes it to the next stage. Dryer turns ON when stage 4 sensors detects the car and do the process for certain time. The next stage is s dual sprayer that sprays water from top as well as bottom to wash the car from both sides. Choose I/O Simulation and simulate this program. To browse Academia.edu and the wider internet faster and more securely, please take a few seconds toupgrade your browser. The next one is a spinning brush system that spins dual brushes to further clean and wipe the vehicle. Ltd grows exponentially through its research in technology. Each stage will be activated by a sensor while the motor driving the conveyor in a constant speed. To practice all PLC programs, here is complete set of 100+ PLC Problems and Solutions. And RUNG002 is used to generate a time delay which terminates the Soaping process by using XIO of T4:0/DN bit after a definite time. IR sensor detects everything whatever restricts the signal but in load cell, particular Low Level and High Level can be set to detect heavily weighted cars only. The system consists of a 4 stage car wash system. Iconic Research and Engineering Journals, 2019, Design of PLC Based Automatic Energy Drink Manufacturing System, Implementation of Smart Car Washing Using GSM PLC, A PROTOTYPE PLC BUILT AUTOMATIC VEHICLE WASHING SYSTEM USING VFD, Design of Automatic Strapping Machine of Express Box for Taobao Sellers, MELSEC FX Series Programmable Logic Controllers Introduction to FX Positioning Control Systems, Review Paper on Automatic Car Washing System, IJSTE - International Journal of Science Technology and Engineering, GOOD PRACTICES GUIDE FOR CAR WASH INSTALLATIONS, Siemens Standard Drives Application Handbook, LM6000-50/60 HZ Gas Turbine Generator Set Product Specification GE Energy 1333 West Loop South Houston, TX 77027 Telephone: 713-803-0900 LM6000 -60Hz Classic 6/2008, Automating Manufacturing Systems with PLCs, Wiring Manual | 2011 Command and Signalling Automation Motor Applications Power Management, DESIGN OF CAR WASHING MACHINE INDUSTRIAL DESIGN PROJECT REPORT, Softstarters Type PSTX30PSTX1250 Installation and commissioning manual, Implementation of Programmable Logic Control Based Industrial Timer Control, ScheduleETechnicalSpecificationHQ120111[1].pdf, DBR - Mechanization Rev 5_April.2013_.pdf, " PLC, SCADA, MOTORS & FREQUENCY DRIVES AT SOFCON INDIA PVT LTD. " VOCATIONAL TRAINING REPORT. You can simulate this process on LogixPro and check all the Test Cases. RUNG001 is used to activate Soaping process which is operated by a switch input I:1/1, when car is detected, Soap sprinklers are activated. The belt now takes the car to the last step there we have DC fans to dry up the vehicle after the wash. At the end of the conveyor, a limit switch is mounted which stops the conveyor and till then Drying is done through RUNG006 and RUNG007 similar to previous operations. RUNG000: This rung is used to create a Master Coil, in other words, Master Start and Stop which controls the entire system. Once the car moves pass the sensor, the stage will be deactivated right away and the next stage is on as long as its sensor detects the car. Here we demonstrate a smart PLC based car wash system that allows for completely automated car washing process. Save my name, email, and website in this browser for the next time I comment. As soon as Soaping is done, RUNG003 has Washing outputs which washes the car by water sprinklers and RUNG004 is used to generate a time delay which terminates the washing process by using XIO of T4:1/DN bit after a definite time. I think we dont need a timer for any stage here. Derived Function Block, #16 PLC Best Practices Create Trend for Cycle Time on HMI.

2011-2022 Sanfoundry. The system consists of a small conveyor type belt that holds on to a car. Car entry sensor triggers the process and turns conveyor belt ON to move the car. ON/OFF operation of conveyor motor is happening in this rung using various conditions like Sensor input and timer done output. This stage has a preliminary sprayer that sprays water on the car and passes it to the next stage. Dryer turns ON when stage 4 sensors detects the car and do the process for certain time. The next stage is s dual sprayer that sprays water from top as well as bottom to wash the car from both sides. Choose I/O Simulation and simulate this program. To browse Academia.edu and the wider internet faster and more securely, please take a few seconds toupgrade your browser. The next one is a spinning brush system that spins dual brushes to further clean and wipe the vehicle. Ltd grows exponentially through its research in technology. Each stage will be activated by a sensor while the motor driving the conveyor in a constant speed. To practice all PLC programs, here is complete set of 100+ PLC Problems and Solutions. And RUNG002 is used to generate a time delay which terminates the Soaping process by using XIO of T4:0/DN bit after a definite time. IR sensor detects everything whatever restricts the signal but in load cell, particular Low Level and High Level can be set to detect heavily weighted cars only. The system consists of a 4 stage car wash system. Iconic Research and Engineering Journals, 2019, Design of PLC Based Automatic Energy Drink Manufacturing System, Implementation of Smart Car Washing Using GSM PLC, A PROTOTYPE PLC BUILT AUTOMATIC VEHICLE WASHING SYSTEM USING VFD, Design of Automatic Strapping Machine of Express Box for Taobao Sellers, MELSEC FX Series Programmable Logic Controllers Introduction to FX Positioning Control Systems, Review Paper on Automatic Car Washing System, IJSTE - International Journal of Science Technology and Engineering, GOOD PRACTICES GUIDE FOR CAR WASH INSTALLATIONS, Siemens Standard Drives Application Handbook, LM6000-50/60 HZ Gas Turbine Generator Set Product Specification GE Energy 1333 West Loop South Houston, TX 77027 Telephone: 713-803-0900 LM6000 -60Hz Classic 6/2008, Automating Manufacturing Systems with PLCs, Wiring Manual | 2011 Command and Signalling Automation Motor Applications Power Management, DESIGN OF CAR WASHING MACHINE INDUSTRIAL DESIGN PROJECT REPORT, Softstarters Type PSTX30PSTX1250 Installation and commissioning manual, Implementation of Programmable Logic Control Based Industrial Timer Control, ScheduleETechnicalSpecificationHQ120111[1].pdf, DBR - Mechanization Rev 5_April.2013_.pdf, " PLC, SCADA, MOTORS & FREQUENCY DRIVES AT SOFCON INDIA PVT LTD. " VOCATIONAL TRAINING REPORT. You can simulate this process on LogixPro and check all the Test Cases. RUNG001 is used to activate Soaping process which is operated by a switch input I:1/1, when car is detected, Soap sprinklers are activated. The belt now takes the car to the last step there we have DC fans to dry up the vehicle after the wash. At the end of the conveyor, a limit switch is mounted which stops the conveyor and till then Drying is done through RUNG006 and RUNG007 similar to previous operations. RUNG000: This rung is used to create a Master Coil, in other words, Master Start and Stop which controls the entire system. Once the car moves pass the sensor, the stage will be deactivated right away and the next stage is on as long as its sensor detects the car. Here we demonstrate a smart PLC based car wash system that allows for completely automated car washing process. Save my name, email, and website in this browser for the next time I comment. As soon as Soaping is done, RUNG003 has Washing outputs which washes the car by water sprinklers and RUNG004 is used to generate a time delay which terminates the washing process by using XIO of T4:1/DN bit after a definite time. I think we dont need a timer for any stage here. Derived Function Block, #16 PLC Best Practices Create Trend for Cycle Time on HMI.

document.getElementById("ak_js_1").setAttribute("value",(new Date()).getTime()); Automatic Coffee Vending Machine PLC Logic, PLC Motor Operation based on Time Cycle Sequence, Industrial Automation and Control Systems (IACS), How to Create DFB in Schneider PLC? Ladder Diagram for Automatic Car Wash Process. To operate this process, for soaping, washing, and drying, four different timers are used. We promise not to spam you. Your email address will not be published. PLC Program for Entry and Exit Control of Car Parking. Sink or Source? I think its simpler and you can see car wash tunnel system on Youtube to check the idea I proposed. You can also follow us on Facebook and Twitter to receive daily updates. Academia.edu no longer supports Internet Explorer. Why Orifice Flow Meter Flange is not Recommended 150# Rating ? You can unsubscribe at any time. NevonProjects works towards development of research based software, embedded/electronics and mechanical systems for research & development purposes. Brusher turns ON when stage 2 sensors detects the car and do the process for certain time. I have some ideas about this particular problem. The system allows for an automated car washing process using PLC to detect vehicle and control its movement at each step. The water poured on vehicle is collected under the mesh of the system and is passed through a filter to reuse for the next wash, thus saving a lot of water unnecessarily wasted in car washes. Allen Bradley PLC Interview Questions and Answers, Start the Counting from a Preset Value in PLC, Configuration of Profibus Network in Siemens PLC, Configuration of Input and Output Tags in Siemens Scada and PLC, Step-by-Step Guide to Choose Right Fuse for a Panel. Steps are, 1) Soaping, 2) Washing, 3) Rinsing and 4) Drying. 2022 Reproduction without explicit permission is prohibited. When a Car enters the hall, a certain sequence is to be followed automatically. Free Instrumentation Course for Trainee Engineers, Single Push button to ON and OFF a Bulb using Ladder Logic. Car wash systems allow for fully automated car wash in a short amount of time. Clean water sprinkler turns ON when stage 3 sensors detects the car and do the process for certain time. When car reached stage 4 sensor conveyor motor should stop and water sprinkler should ON for 10 sec.if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[336,280],'instrumentationtools_com-banner-1','ezslot_20',166,'0','0'])};if(typeof __ez_fad_position!='undefined'){__ez_fad_position('div-gpt-ad-instrumentationtools_com-banner-1-0')}; When car reached exit ,car exit sensor will trigger the car wash done indication lamp(O:0/7). At the end of water sprinkler timer, Conveyor will again ON because of the parallel contact in rung 0002. Download Project Document/Synopsis Many of the electronic appliances work on 12VDC, and if its portable appliance it, Download Project Document/Synopsis Drones are capable of highly advanced surveillance, and drones already in use by enforcement, Your email address will not be published. RUNG005 is activated as soon as the washing process is done. To detect the car automatically, load cells can be used, or any other sensor such as Infrared Sensor can also be used. This is a PLC Program to Implement an Automatic Car-Wash Process. Sanfoundry Global Education & Learning Series PLC Algorithms. Normally Open or Normally Closed? Soapy water sprinkler turns ON when stage 1 sensor detects the car and do the process for certain time. Load Cell can be here more effective here than IR sensors. 2WD Vehicle Drone Air + Land Surveillance, Design and Fabrication of Bucket Conveyor System, Signature verification System using Python, Car Lane Detection Using NumPy OpenCV Python. Car entry sensor triggers the memory bit which will turn on conveyor motor. To activate this system, this Master Start has to be pressed. Required fields are marked *. Here is PLC program to Implement an Automatic Car-Wash Process, along with program explanation and run time test cases. On detection the system now starts the belt movement using a motorized system and vehicle moves to the first stage. Car exit sensor triggers conveyor motor to turn off. -. You can download the paper by clicking the button above. When car reached stage 1 sensor conveyor motor should stop and water sprinkler should ON for 10 sec.

When car reached stage 2 sensor conveyor motor should stop and brusher should ON for 10 sec. The ladder logic of Automatic Car Washing Process using PLC Ladder Diagram explanation as follows : Latching rung to operate the system through Master Start and Stop PB. How to Size a Cable for Industrial AC Motors? Implement this process sequence in PLC using Ladder Diagram programming language. Program done in Allen Bradley RSLogix 500 PLC Software. How to use JUMP Instruction in PLC Ladder Logic? here is complete set of 100+ PLC Problems and Solutions, Prev - PLC Program to Maintain the Capacity of a Particular Classroom, Next - PLC Program to Operate 4 Outputs Simultaneously with Time Delay, PLC Program for Oil and Water Separation Process, PLC Program for Cleaning and Rinsing Bottles in Beverage Industries, PLC Program to Implement 2-bit Magnitude Comparator, C Program to Implement Binary Search with Window, PLC Program to Store Data of Various Process Sequentially, Mechatronics Questions and Answers Microprocessor Based Controllers, PLC Program to Control Conveyor Sequence with Interlock, PLC Program for Burglar Alarm Security System, C Program to Implement Rabin-Karp Method for Pattern Searching, Chemical Process Calculation MCQ Questions, Chemical Process Technology MCQ Questions. All Rights Reserved.

Worst cases are checked. Soaping, Washing, Rinsing and Drying are performed for a particular time, hence to generate time delay for these outputs become mandatory. The above explained automatic car wash using PLC is for example only. At the end of brushing process, Conveyor will again ON because of the parallel contact in rung 0002.if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[300,250],'instrumentationtools_com-box-4','ezslot_15',165,'0','0'])};if(typeof __ez_fad_position!='undefined'){__ez_fad_position('div-gpt-ad-instrumentationtools_com-box-4-0')}; When car reached stage 3 sensor conveyor motor should stop and water sprinkler should ON for 10 sec. It has motor coils output to run the conveyer on which car moves to the last step of car washing, drying of car. Started in 2012 NevonProjects an initiative by NevonSolutions Pvt. Enter the email address you signed up with and we'll email you a reset link. Sorry, preview is currently unavailable. If you liked this article, then please subscribe to our YouTube Channel for PLC and SCADA video tutorials.